In the ever-evolving landscape of manufacturing and construction, the significance of

precision tools cannot be overstated. The

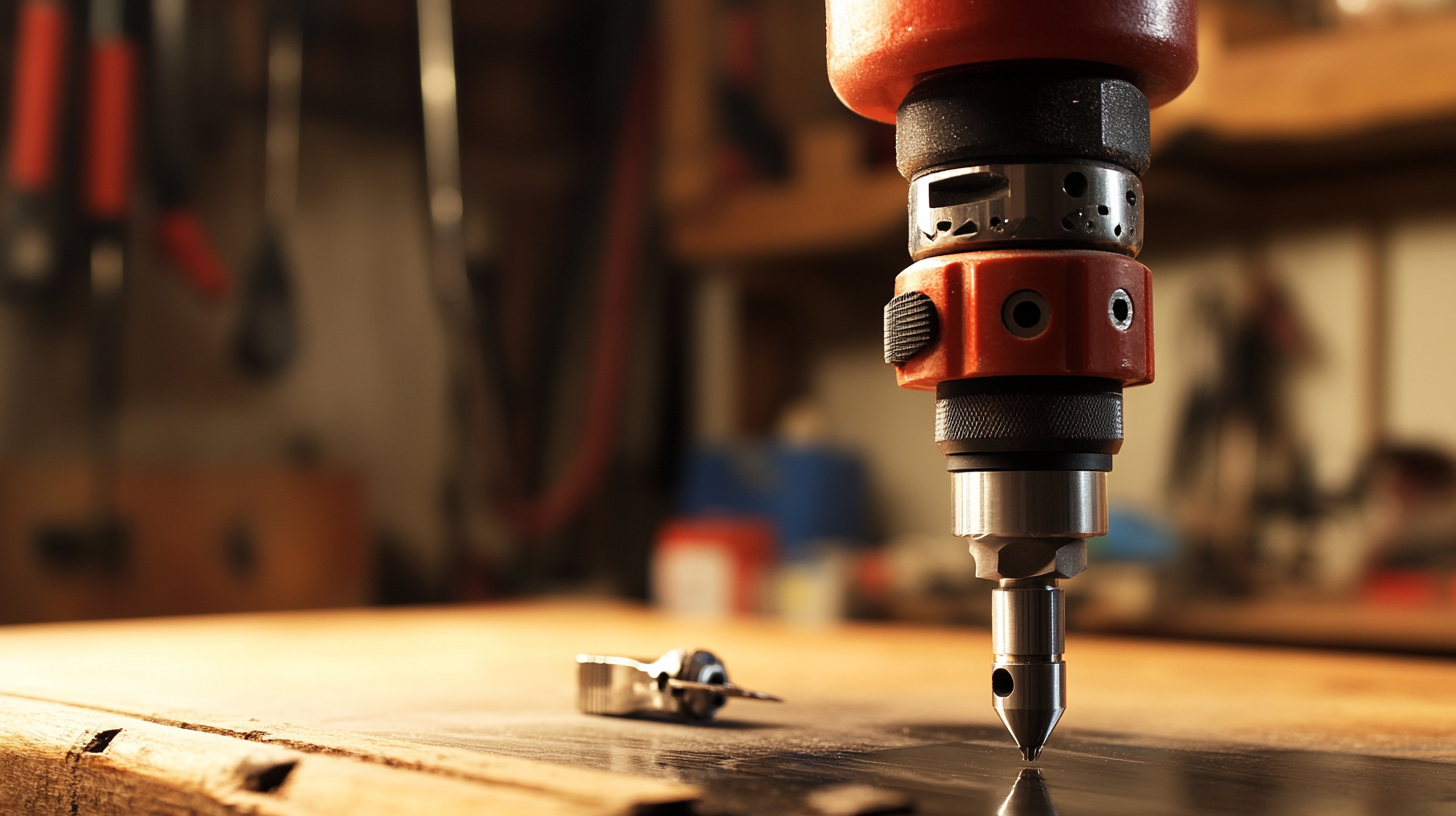

Pneumatic Right Angle Drill emerges as a vital instrument,

particularly in applications requiring accessibility in constrained spaces. According to industry reports,

the global pneumatic tools market is projected to reach

USD 18.3 billion by 2026, growing at a CAGR of

5.3% from 2021. This increase is driven by the

rising demand for efficient and reliable tools across numerous sectors, including automotive, aerospace,

and construction. The unique design of the Pneumatic Right Angle Drill allows for enhanced maneuverability,

enabling operators to execute intricate drilling tasks that would otherwise be challenging with traditional drills.

As China continues to lead the way in manufacturing innovation, the integration of advanced technology

into these tools not only bolsters productivity but also reinforces the strength of

"China's manufacturing power" on the global stage.

In the ever-evolving landscape of manufacturing and construction, the significance of

precision tools cannot be overstated. The

Pneumatic Right Angle Drill emerges as a vital instrument,

particularly in applications requiring accessibility in constrained spaces. According to industry reports,

the global pneumatic tools market is projected to reach

USD 18.3 billion by 2026, growing at a CAGR of

5.3% from 2021. This increase is driven by the

rising demand for efficient and reliable tools across numerous sectors, including automotive, aerospace,

and construction. The unique design of the Pneumatic Right Angle Drill allows for enhanced maneuverability,

enabling operators to execute intricate drilling tasks that would otherwise be challenging with traditional drills.

As China continues to lead the way in manufacturing innovation, the integration of advanced technology

into these tools not only bolsters productivity but also reinforces the strength of

"China's manufacturing power" on the global stage.

Pneumatic right angle drills are a game changer in various industrial applications, offering a unique blend of power and precision that traditional tools often lack. Their compact design allows them to access tight spaces where larger equipment may struggle to operate, making them ideal for tasks in automotive assembly lines, machinery maintenance, and even in construction scenarios where maneuverability is key. The ergonomic design of these drills minimizes user fatigue, enabling professionals to work efficiently without compromising on performance.

In addition to their capability for high torque output, pneumatic right angle drills excel in environments where electric tools may face limitations, such as explosive atmospheres or wet conditions. Industries like manufacturing and aerospace have embraced these tools for their reliability and reduced risk, paving the way for innovative applications. As technology continues to evolve, these drills remain integral to workflows that demand both strength and flexibility, ensuring they stay at the forefront of industrial tool solutions.

Pneumatic right angle drills have become a favorite among professionals for their unique capabilities and benefits, especially when compared to traditional electric models. One of the most significant advantages is their superior power-to-weight ratio. These air-powered tools deliver high torque while remaining lightweight, making them ideal for use in tight, confined spaces where electric drills might struggle. This feature is particularly beneficial in automotive and industrial settings, where precision and efficiency are paramount.

Pneumatic right angle drills have become a favorite among professionals for their unique capabilities and benefits, especially when compared to traditional electric models. One of the most significant advantages is their superior power-to-weight ratio. These air-powered tools deliver high torque while remaining lightweight, making them ideal for use in tight, confined spaces where electric drills might struggle. This feature is particularly beneficial in automotive and industrial settings, where precision and efficiency are paramount.

Another key benefit of pneumatic right angle drills lies in their consistent performance. Unlike electric models, which can experience fluctuations in power as battery levels deplete, pneumatic drills maintain a steady output, allowing for uninterrupted work even on the most demanding tasks. Furthermore, they tend to generate less heat and are less prone to overheating, contributing to a longer lifespan. As the industry evolves, the resurgence of pneumatic tools in various applications highlights their enduring relevance and effectiveness, making them a go-to choice for professionals seeking reliability in their toolkit.

The rise of pneumatic tools in manufacturing and construction is a significant trend driving innovation and efficiency across various industries. As the demand for high-performance tools increases, the pneumatic tools and accessories market is expected to grow substantially, reaching approximately USD 18.10 billion by 2034. This surge highlights the growing preference for pneumatic options over traditional electric tools due to their superior power-to-weight ratio and versatility.

Pneumatic right angle drills are powerful tools often used in tight spaces where traditional drills can't reach. However, safety considerations must be prioritized to ensure efficient and safe operation. According to industry reports, over 45% of hand tool injuries occur due to improper use or lack of safety measures. To mitigate these risks, always wear appropriate personal protective equipment (PPE), including safety goggles and gloves, to protect against debris and potential pinch points in tight working environments.

When utilizing pneumatic right angle drills, it’s essential to maintain a firm grip and control over the tool. Tips for safe operation include securing the workpiece to prevent it from moving during drilling, using the right air pressure as specified by the manufacturer, and ensuring the drill's hoses are free from damage. A well-maintained drill can operate at pressures typically ranging from 80 to 100 PSI, but it's crucial to adhere to the specified limits to prevent tool failure and accidents.

Furthermore, regular inspections and maintenance of both the tool and its air supply are vital for safety and optimal performance. Keep an eye out for signs of wear, and replace any damaged components immediately. Engaging in preventive measures can significantly reduce the likelihood of tool-related injuries and enhance the overall efficiency of your pneumatic right angle drill.

| Application | Safety Considerations | Best Practices |

|---|---|---|

| Automotive Assembly | Ensure proper ventilation to avoid fume inhalation. | Use a torque controller for consistent results. |

| Woodworking | Wear safety goggles to protect against debris. | Keep work area clear of obstacles. |

| Construction | Check for loose clothing that could get caught in the drill. | Regularly inspect drill for air leaks. |

| Metal Fabrication | Use hand protection to avoid cuts and abrasions. | Maintain sharp drill bits for efficiency. |

| Electronics Assembly | Be cautious of static electricity; use anti-static gear. | Work on grounded surfaces. |

Pneumatic right angle drills are increasingly recognized for their versatility and efficiency in various industries, from automotive to construction. A recent industry report indicates that the global pneumatic tools market is projected to reach $28 billion by 2026, highlighting the growing reliance on these tools for precision tasks. Case studies from manufacturers reveal that pneumatic right angle drills excel in tight spaces, significantly improving assembly line productivity. For example, one automotive assembly plant reported a 25% reduction in time spent on bolt installation due to the ergonomic design and power efficiency of pneumatic right angle drills.

When utilizing pneumatic right angle drills, safety and efficiency are paramount. Tip: Always ensure proper ventilation and use appropriate personal protective equipment (PPE) to mitigate any risks associated with compressed air tools. Additionally, consider using high-performance drill bits designed for specific materials to enhance durability and performance. This tailored approach not only boosts productivity but also extends the life of your tools.

Another notable application can be found in the renovation sector, where contractors use pneumatic right angle drills for tasks like drywall installation and plumbing. A 2022 survey found that 78% of contractors reported improved access to confined spaces when using these drills, leading to faster project completion times. Tip: Regular maintenance of your pneumatic tools is essential; a clean and well-lubricated drill will perform better and last longer, ensuring maximum efficiency on the job site.