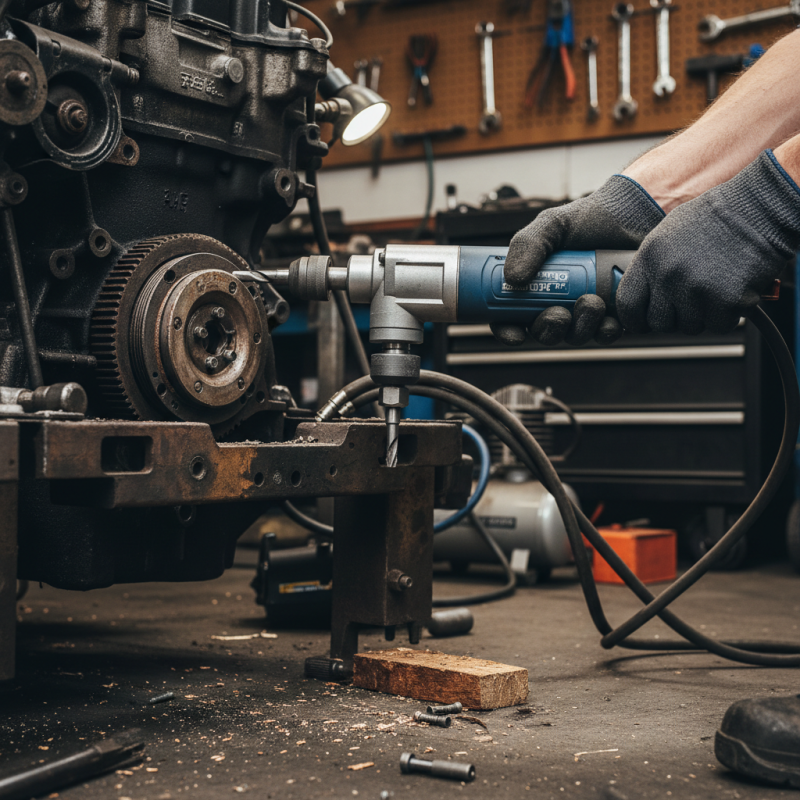

When it comes to optimizing your workshop efficiency and precision, choosing the right tools is essential. Among the myriad of options available for various tasks, the Pneumatic Right Angle Drill stands out as an invaluable asset for both professionals and hobbyists alike. These specialized tools are designed to access tight spaces and deliver formidable torque, making them ideal for a wide range of drilling applications. Whether you are working on automotive repairs, cabinetry, or intricate mechanical assemblies, the versatility of a pneumatic right angle drill can significantly ease the process.

In this article, we will explore the top ten pneumatic right angle drills that can cater to your workshop needs. From ergonomic designs to impressive power ratings, we will highlight the features that make each of these tools a must-have for any serious craftsman. Understanding the benefits and functionalities of these drills enables you to make an informed decision and enhance your project outcomes. Join us as we delve into the world of pneumatic right angle drills and uncover the best options to elevate your workshop efficiency.

Pneumatic right angle drills are essential tools for any workshop, offering distinct advantages over their electric counterparts. The primary benefit lies in their power and torque, which are generated through compressed air instead of an electric motor. This design allows for a lighter and more compact tool, making it easier to maneuver in tight spaces. Additionally, pneumatic drills are less likely to overheat during prolonged use, ensuring they can operate efficiently in demanding projects.

When selecting a pneumatic right angle drill, consider how frequently you'll use it and the types of materials you'll be working with. It's important to ensure that the drill has the appropriate torque settings for your needs. For optimal performance, maintain your air compressor and ensure the fittings of the drill are free of debris, as this can affect airflow and overall functionality.

Tip: Always use the right sized bits and attachments for your project. This not only enhances efficiency but also prolongs the life of your drill. Furthermore, wearing safety gear such as goggles and gloves is crucial to protect yourself from potential debris and ensure a safe working environment.

| Model | Max RPM | Air Consumption (CFM) | Weight (lbs) | Key Features |

|---|---|---|---|---|

| Model A | 2,000 | 4.5 | 2.5 | Compact Design, High Torque |

| Model B | 1,800 | 5.0 | 3.0 | Ergonomic Grip, Variable Speed |

| Model C | 2,500 | 6.0 | 2.2 | Durable Build, Fast Rotation |

| Model D | 2,200 | 5.5 | 2.8 | Lightweight, Adjustable Handle |

| Model E | 2,000 | 4.2 | 2.6 | Quiet Operation, Low Vibration |

| Model F | 1,900 | 5.8 | 3.1 | Strong Torque, Compact |

| Model G | 2,400 | 4.8 | 2.0 | Robust, High Performance |

| Model H | 1,750 | 6.2 | 3.3 | Flexibility in Tight Spaces |

| Model I | 2,100 | 5.1 | 2.4 | Versatile, Easy Control |

| Model J | 2,300 | 4.6 | 2.7 | Professional Grade, High Efficiency |

When selecting a pneumatic right angle drill for your workshop, several key features should be prioritized to ensure optimal performance and efficiency. First and foremost, the drill's torque specification is crucial, as it impacts the tool's ability to handle tough materials and various applications. Look for models that offer adjustable torque settings to provide versatility for different tasks, from driving screws to drilling into hard surfaces. Additionally, consider the drill's RPM (revolutions per minute) rating, as higher RPMs typically lead to faster work completion, particularly in tasks requiring precision.

Another essential aspect is the tool’s ergonomics and weight. A lightweight design can reduce operator fatigue, especially during extended use, while an ergonomic handle enhances grip and control. It is also important to check the size of the drill head; a compact design allows for operation in tight spaces, making your work more efficient. Lastly, be mindful of the noise level generated by the tool, as quieter models can contribute to a more comfortable working environment. By focusing on these features, you can choose a pneumatic right angle drill that best suits your workshop needs.

This chart compares the top 10 pneumatic right angle drills based on key features such as torque, air consumption, and weight. This information can help you make an informed decision for your workshop needs.

When it comes to equipping your workshop with the right tools, pneumatic right angle drills are essential for reaching tight spaces while providing ample power for various applications. These drills are designed to effectively handle tasks that require precision and torque, making them a favorite among professionals and hobbyists alike. When selecting a pneumatic right angle drill, factors such as torque output, RPM, and overall ergonomics should be considered to ensure optimal performance and comfort during prolonged use.

The top recommended pneumatic right angle drills combine lightweight construction with robust power delivery. Many models feature adjustable speed settings, allowing users to tailor their drilling experience based on the material and specific task at hand. Additionally, an ergonomic design minimizes fatigue, enabling users to work for extended periods without discomfort. Look for models with built-in safety features such as enhanced grips and reliable switches, which contribute to the overall safety and effectiveness of your drilling operations. These characteristics make the top choices ideal for woodworkers, metal fabricators, and maintenance professionals looking to streamline their workflow.

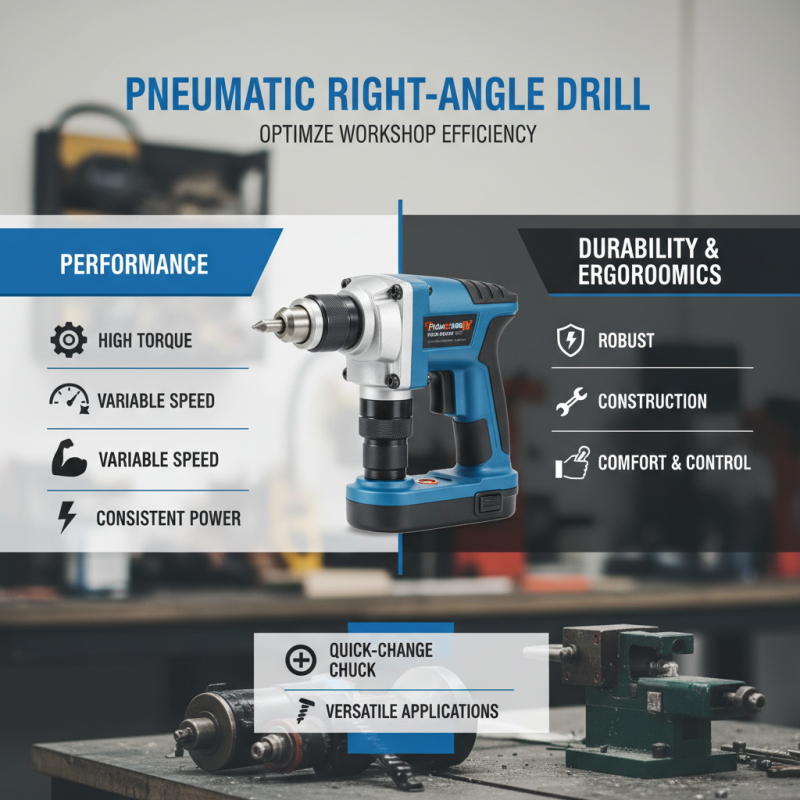

When it comes to pneumatic right angle drills, performance and durability are crucial factors that can significantly impact your workshop's efficiency. Performance is often measured by the tool's torque, speed, and ability to maintain consistent power under load. A drill that can deliver high torque while operating at varying speeds offers versatility for different tasks, from precision drilling to driving screws in tight spaces. Additionally, features like quick-change chucks and ergonomic designs enhance user comfort and facilitate faster work processes, making these drills ideal for both professional and DIY applications.

Durability, on the other hand, hinges on the quality of materials used in construction and the design's resilience to wear and tear. Tools made with robust metals and high-quality components tend to withstand the stresses of prolonged use, which is essential for maintaining reliability in demanding environments. Factors such as protective casings and enhanced lubrication systems also play a vital role in prolonging the lifespan of pneumatic drills. Ultimately, selecting a drill that balances performance with durability ensures that you are equipped to handle various tasks in your workshop for years to come.

Pneumatic right angle drills are essential tools in many workshops, known for their compact design and ability to navigate tight spaces. To ensure that these tools remain effective and long-lasting, proper maintenance is crucial. According to a report by the Machinery Maintenance Institute, nearly 40% of pneumatic tool failures are attributed to inadequate maintenance practices. Regular inspections and thorough cleaning of the tool can significantly reduce the risk of unexpected downtimes and extend its lifespan.

One effective maintenance tip is to routinely lubricate the air motor and other moving parts. Utilizing the right type of lubricant, as recommended by manufacturers, can enhance mechanical performance and reduce wear. It is also important to keep the air intake filter clean, as clogged filters can lead to reduced efficiency and overheating. Additionally, maintaining the correct air pressure—typically around 90 to 100 PSI for right angle drills—ensures optimal operation and prevents potential damage from excessive pressure, according to industry standards cited by the National Tool Association. By adopting these maintenance practices, users can greatly enhance the longevity and reliability of their pneumatic right angle drills, keeping their workshop running smoothly.