Using an Electric Conveyor Belt Cutter can enhance productivity in various industries. This tool simplifies cutting tasks, making it essential for many operations. However, to maximize its benefits, users must be well-informed.

Operating an Electric Conveyor Belt Cutter requires attention to detail. Safety is paramount. Understand the machine's components and functions before use. It’s easy to overlook maintenance, yet it is crucial for optimal performance. Regularly check for wear and tear.

Additionally, proper handling techniques are vital. Incorrect usage can lead to accidents or damaged materials. Train operators on best practices. Remember, practice is key. Mistakes happen, and learning from them is part of the process. Ultimately, mastering the Electric Conveyor Belt Cutter improves workflow and efficiency.

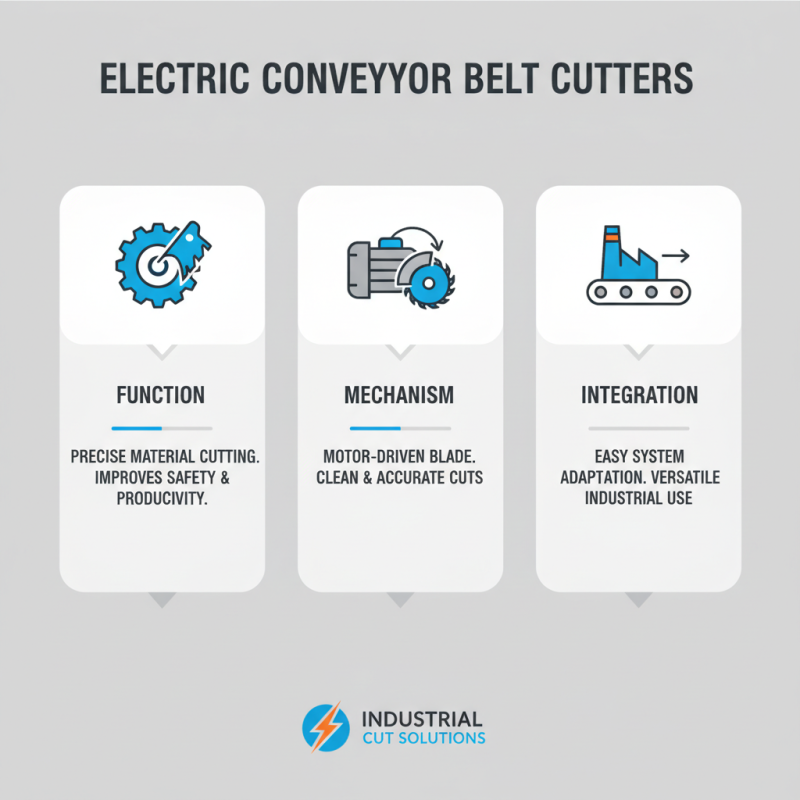

Electric conveyor belt cutters are essential tools in a variety of industries. They are used to cut different materials efficiently. Understanding how they work can improve safety and productivity. These cutters operate using a motor to drive a blade. The blade makes a clean and precise cut. Their design allows for easy integration into existing systems.

Using an electric cutter requires some knowledge. It's crucial to select the right type of blade for the material. This choice affects the cutting quality. Operators need to be trained to use the equipment properly. Safety protocols must be followed to prevent accidents. Mistakes can lead to injuries or damage to the machine. Regular maintenance is also necessary. A dull blade can cause issues and affect performance.

There are challenges when using these cutters. They require a power source and can have operational limits. Unforeseen problems may occur during the cutting process. Adjustments might be needed to maintain efficiency. Learning from these experiences can lead to improvements in operations. Understanding the basics helps in addressing these challenges effectively.

Electric conveyor belt cutters are essential tools in various industries. However, safety precautions are crucial to prevent accidents. According to industry reports, over 30% of workplace injuries involve machinery accidents. Proper handling of electric conveyor belt cutters can significantly reduce these risks.

Always wear protective gear, such as gloves and goggles. This minimizes exposure to potential hazards. Keep the cutting area clean and organized. Clutter can obscure visibility, leading to mishaps. Training is vital as well. Workers should know how to operate the cutter safely and efficiently.

In 2021, the Occupational Safety and Health Administration (OSHA) reported nearly 1,500 injuries related to improper machine use. Double-check that the machine is correctly set up before starting. Misalignment can cause severe injuries. Regular inspection and maintenance reduce the chances of equipment failure. Remember, even small lapses in safety can lead to significant consequences. Stay vigilant and prioritize safety.

Setting up an electric conveyor belt cutter can seem daunting. Start by choosing a flat, stable surface for your machine. Ensure it is close to a power source. This will make the process smoother. Position the conveyor belt properly to allow free movement.

Before using the cutter, check the blade's sharpness. Dull blades can lead to uneven cuts. Always wear safety gloves for protection. Adjust the height of the conveyor belt. This ensures that materials are fed in easily. A proper height reduces the risk of accidents.

Here are some tips. Regularly inspect all parts of the cutter. Check for any signs of wear or damage. Lubricate moving parts to prevent friction. Also, keep the workspace clear. This minimizes distractions during operation. It’s easy to overlook small details. But, small mistakes can lead to bigger problems. Taking a moment to reflect on these aspects ensures a safer cutting experience.

When using an electric conveyor belt cutter, proper technique is crucial for effective cutting. Start by ensuring the material is securely positioned on the conveyor belt. Loose materials can shift during cutting, leading to uneven edges. Take time to adjust the speed settings on your cutter. A slower speed often results in cleaner cuts. However, too slow can lead to friction and singeing.

Pay attention to the blade condition. A dull blade can create a rough finish and increase cutting time. Regularly inspect the blade for damage or wear. Replace it if necessary to maintain cutting quality. When operating the cutter, keep hands clear of moving parts. It’s easy to become distracted, especially in a busy environment. Focus on the task at hand.

Setting up the work area matters as well. Ensure good lighting to see the cutting line clearly. Clutter can be distracting and pose hazards. Remember that practice makes perfect. If your cuts are not as precise as desired, take a moment to assess your approach. Reflect on your pressure and speed. With attention to detail, efficiency improves over time.

Maintaining an electric conveyor belt cutter is crucial for its longevity. Regular cleaning helps prevent dust and debris buildup. Use a soft brush or cloth to wipe the surfaces. Ensure the blade area is free of obstructions. It’s easy to overlook this step, yet it can lead to reduced performance over time.

Inspect the cutting blade frequently. A dull blade causes more wear on the machine. Replace it when necessary. Sharp blades ensure cleaner cuts and reduce motor strain. Don’t forget to lubricate moving parts. This helps maintain smooth operation. However, be careful. Over-lubrication can attract dirt and grime.

Check the electrical components regularly. Look for frayed wires or loose connections. These issues can lead to unexpected failures. Keeping an eye on these elements is often neglected. Document any maintenance actions. This creates awareness about what needs attention. By focusing on these details, you can extend the life of your electric conveyor belt cutter significantly.