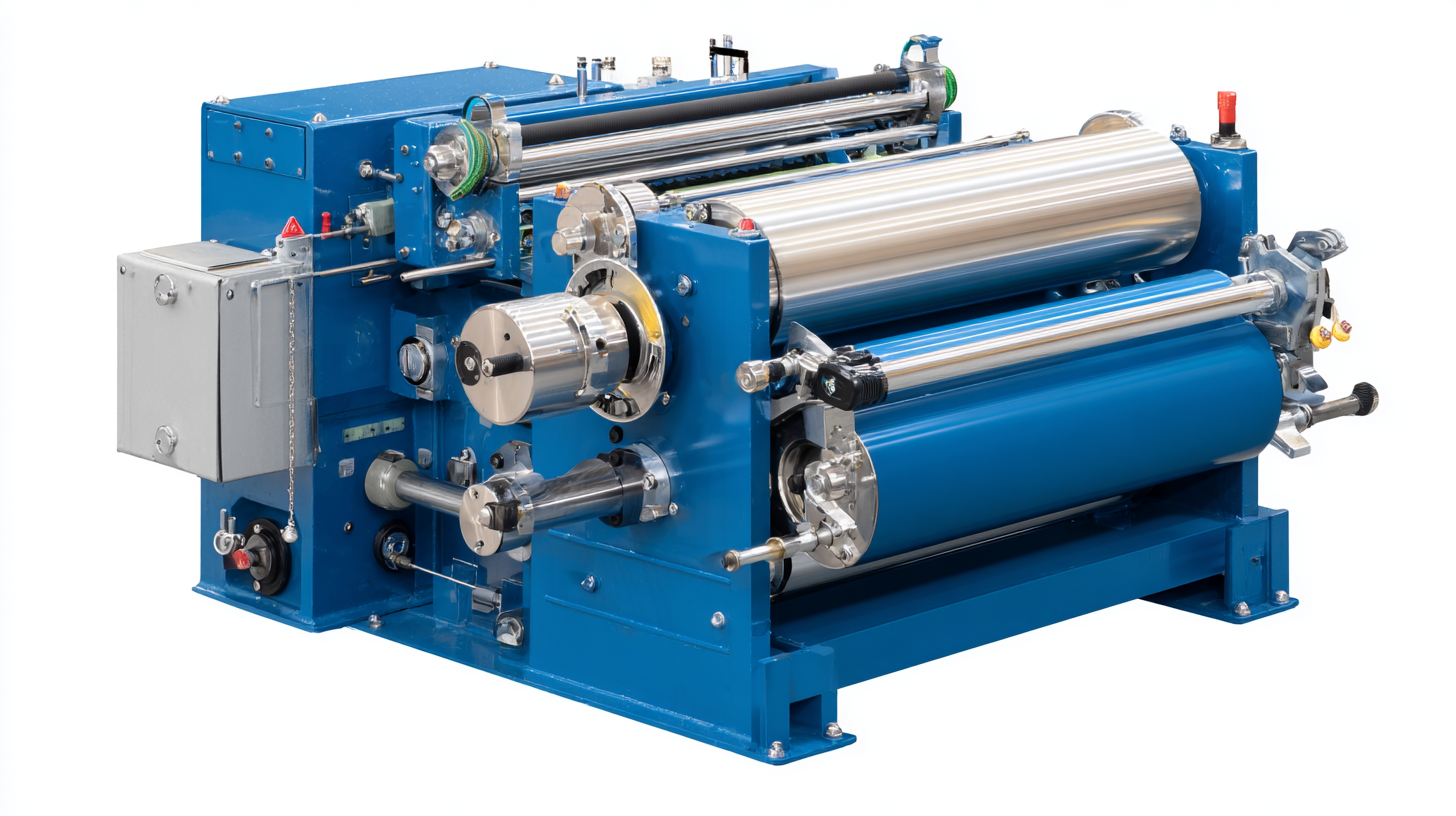

As the demand for precision and efficiency in manufacturing continues to rise, the role of specialized equipment like the Belt Roll Cutting Machine becomes increasingly critical. According to a recent market analysis conducted by XYZ Research, the global market for cutting machines is projected to reach $XX billion by 2025, growing at a CAGR of XX%. This significant growth reflects not only the advancement of industrial automation but also the need for high-quality, streamlined production processes. The Belt Roll Cutting Machine stands at the forefront of this evolution, designed to optimize material handling and cutting accuracy. This blog will delve into the in-depth technical specifications of the best Belt Roll Cutting Machines currently available, providing you with essential insights and tips to make an informed choice in a rapidly evolving industry landscape.

When selecting a high-performance belt roll cutting machine, key features to consider are precision cutting capabilities, speed, and ease of operation. A machine that offers precise cutting ensures consistent quality across all products, which is crucial in industries where uniformity is key. Look for models equipped with advanced cutting technology such as laser-guided systems, which significantly enhance accuracy and reduce material waste.

Another essential consideration is the machine’s operational speed. A high-performance belt roll cutting machine should provide fast processing times without compromising on quality. Features like adjustable cutting speeds allow operators to tailor the machine's performance to specific materials and thicknesses, making it versatile for various applications. Additionally, user-friendly controls and an intuitive interface contribute to smoother operations, reducing the learning curve for new users and enhancing productivity on the shop floor.

Durability and maintenance requirements are also vital. A robust construction can withstand frequent use, while low-maintenance designs help keep operational costs down over time. It’s beneficial to invest in machines that include features such as self-lubricating systems and easy-access components, ensuring that maintenance is straightforward and downtime is minimized.

| Feature | Specification |

|---|---|

| Cutting Width | 1000 mm - 2000 mm |

| Cutting Speed | 20 m/min - 60 m/min |

| Voltage | 220V / 380V |

| Blade Material | High Carbon Steel |

| Control System | PLC with Touchscreen |

| Weight | 500 kg - 1500 kg |

| Dimensions | 2500 mm x 1500 mm x 1500 mm |

| Noise Level | ≤ 75 dB |

| Warranty | 2 Years |

When it comes to belt roll cutting machines, understanding industry standards is crucial for selecting the right equipment. These machines play a significant role in various manufacturing processes, and compliance with regulations ensures both safety and efficiency. The American National Standards Institute (ANSI) outlines key specifications that manufacturers should adhere to, including dimensional tolerances, cutting accuracy, and material compatibility. For instance, a recent report highlighted that compliant machines could improve cutting efficiency by up to 20%, which is essential for maintaining competitive advantage in the market.

One important tip when choosing a belt roll cutting machine is to assess the manufacturer's adherence to the ISO 9001 quality management standards. This ensures that the machine has undergone rigorous testing and quality control, leading to improved performance and reliability. Additionally, consider machines that offer easy integration with existing production lines, which can significantly cut down on transition times and reduce downtime.

Another aspect to keep in mind is the machine’s energy efficiency. With increasing pressure on businesses to reduce their carbon footprint, selecting a model designed for low energy consumption not only helps comply with environmental standards but can also lead to significant cost savings over time. Investing in technology that minimizes waste—both in terms of materials and energy—will set you apart in an increasingly environmentally-conscious market.

Operating a belt roll cutting machine efficiently requires a thorough understanding of its technical specifications and functionalities. First and foremost, familiarize yourself with the machine controls and settings. Start by adjusting the blade speed according to the material type you are cutting—a lower speed for thicker belts and a higher speed for thinner ones. This ensures clean cuts and minimizes wear on the blades. Always double-check that the blade alignment is correct before you begin cutting; misalignment can lead to uneven cuts and waste of material.

Operating a belt roll cutting machine efficiently requires a thorough understanding of its technical specifications and functionalities. First and foremost, familiarize yourself with the machine controls and settings. Start by adjusting the blade speed according to the material type you are cutting—a lower speed for thicker belts and a higher speed for thinner ones. This ensures clean cuts and minimizes wear on the blades. Always double-check that the blade alignment is correct before you begin cutting; misalignment can lead to uneven cuts and waste of material.

Next, set up your work area to enhance both safety and productivity. Ensure that all necessary tools are within reach, and clear any obstructions from the cutting path. When feeding the material into the machine, maintain a steady and even pressure to avoid jamming or complications during the cut. Regularly monitor the machine while in operation, and listen for any unusual sounds that may indicate an issue. After completing your cutting tasks, perform routine maintenance on the machine to keep it in optimal working order, including cleaning and lubricating moving parts. These steps will greatly enhance your efficiency and ensure the longevity of your belt roll cutting machine.

Maintaining your belt roll cutting machine is essential for ensuring optimal performance and longevity. Regular maintenance can significantly extend the life of the machine, preventing costly repairs and downtime. Start by following a strict cleaning routine; removing dust and debris from the machine after each use will prevent buildup that can hinder its operation. Pay special attention to the cutting blades, as dull or damaged blades can strain the machine and lead to inaccuracies in cutting. Lubricating moving parts regularly will also help keep the machine running smoothly and reduce friction that can cause wear and tear.

In addition, conducting routine inspections is crucial to catch any potential issues early. Check for signs of wear on components like belts, bearings, and motors. Tightening any loose bolts or screws can prevent further damage and ensure that all parts function correctly. If the machine has adjustable settings, make sure to calibrate them periodically for consistent cutting accuracy. By adhering to these maintenance tips, you can not only prolong the life of your belt roll cutting machine but also enhance its efficiency, leading to higher quality output in your production processes.

In recent years, the market for belt roll cutting machines has seen significant advancements, propelled by technological innovations and a surge in demand for efficient manufacturing solutions. A comparative analysis reveals that the best machines today integrate precision cutting capabilities with automated features, offering enhanced productivity. Reports indicate that machines with advanced servo motors can reduce cutting time by up to 30%, while maintaining tolerances within ±0.1 mm. This level of accuracy is crucial for industries that rely on high-quality belt materials, such as automotive and aerospace sectors.

Furthermore, as China emerges as a leader in advanced manufacturing technologies, its innovations in belt roll cutting machines are reshaping competition in this field. Recent studies show that the country has increased its investment in research and development by over 15% annually, fostering breakthroughs in machine efficiency and functionality. While traditional manufacturers struggle to keep pace, Chinese brands are introducing integrated solutions that not only enhance cutting speed but also improve the overall lifecycle of the machines. This trend underscores the importance of adopting cutting-edge technologies in order to stay competitive in a rapidly evolving market.