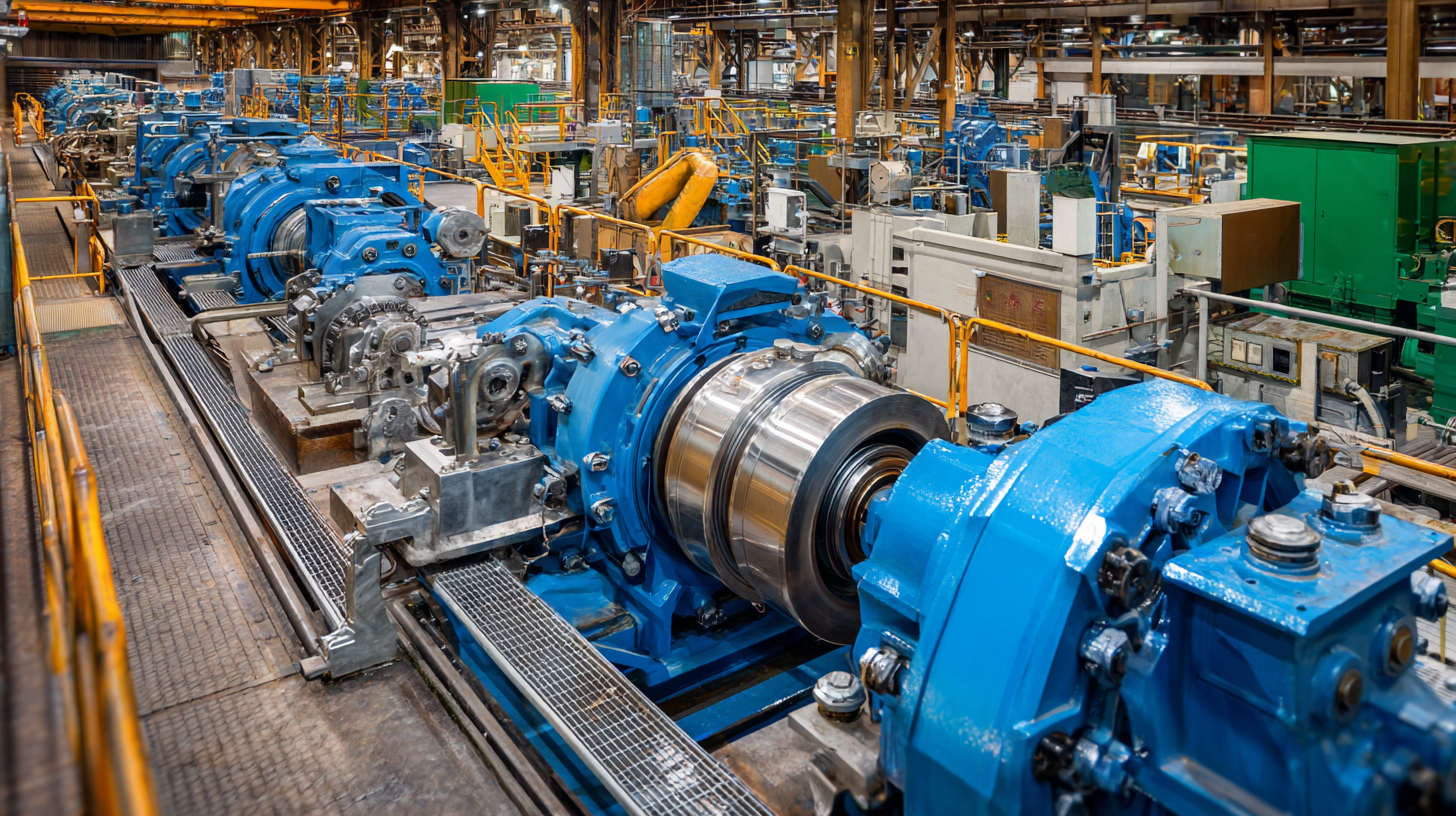

In the fast-evolving landscape of industrial operations, the role of Rubber Belt Traction Machines has emerged as a pivotal factor in enhancing efficiency and productivity. According to a recent report by Markets and Markets, the global belt drive market is projected to reach USD 24.4 billion by 2025, underscoring the growing significance of advanced traction systems across various industries. These machines not only optimize material handling processes but also significantly reduce energy consumption, with studies indicating a potential energy savings of up to 30% compared to traditional systems. As manufacturers increasingly adopt automation and smart technologies, Rubber Belt Traction Machines stand at the forefront, offering innovative solutions that cater to the demands of modern production environments. By harnessing their capabilities, industries can expect not only to streamline operations but also to achieve sustainable growth and improved operational metrics.

Rubber Belt Traction Machines have become pivotal in enhancing industrial performance through their efficient movement and transportation capabilities. Understanding their mechanisms reveals how the rubber belt's design contributes to smooth operation, reduced wear, and improved load handling. The traction provided by rubber belts allows for better control and speed variations, making them ideal for various applications, from manufacturing to distribution. Their adaptability to different environments highlights their significance in optimizing workflows, particularly in industries that require robust and reliable conveyor systems.

However, the effectiveness of these machines heavily relies on stringent adherence to safety protocols and the fit-for-purpose design of the conveyor systems. In sectors like quarrying, the implementation of safety measures—including anti-rollback technology—is essential to mitigate the inherent risks associated with heavy machinery. Neglecting such protocols can lead to devastating consequences, as shown in recent reports regarding safety failures in various settings. Therefore, understanding the operational mechanisms of rubber belt traction machines is not just about enhancing efficiency; it is equally about prioritizing safety and ensuring a secure working environment for all employees involved.

This bar chart illustrates the efficiency percentage of rubber belt traction machines over the first seven months of the year, showcasing a significant increase in performance through this period.

Rubber belt traction machines are transforming the landscape of industrial performance by offering a range of key benefits that streamline operations and enhance productivity. One significant advantage is their ability to improve operational efficiency. These machines provide consistent power transmission, allowing for smoother and more reliable workflow across various industrial processes. As a result, businesses can reduce downtime and optimize their production schedules.

Rubber belt traction machines are transforming the landscape of industrial performance by offering a range of key benefits that streamline operations and enhance productivity. One significant advantage is their ability to improve operational efficiency. These machines provide consistent power transmission, allowing for smoother and more reliable workflow across various industrial processes. As a result, businesses can reduce downtime and optimize their production schedules.

Tip: When implementing rubber belt traction, ensure proper installation and maintenance to maximize their lifespan and performance. Regular inspections can help identify wear and prevent potential breakdowns, ultimately saving costs in the long run.

Another notable benefit is the flexibility of rubber belt systems. They can be easily adapted to various applications, making them suitable for industries ranging from manufacturing to logistics. This adaptability ensures that businesses can tailor their machinery to meet specific operational needs without significant reconfiguration.

Tip: Choose the right type of rubber belt based on the materials being transported and the environment in which they operate. Using specialized belts can enhance traction and reduce slippage, contributing to overall effectiveness in performance.

Maintaining rubber belt traction machines is crucial for maximizing their efficiency and long-term performance in various industries. According to a report by the International Rubber Study Group, proper maintenance can enhance the lifespan of rubber belts by up to 30%, significantly reducing the frequency of replacements. Regular inspections, which include checking for wear and tear, alignment issues, and tension levels, are vital in preventing unexpected breakdowns that could lead to costly downtime.

Furthermore, optimizing the operating conditions of these systems can yield substantial efficiency gains. A study from the Belt Conveyor Manufacturer’s Association highlights that adjusting the tension and ensuring proper lubrication can improve energy efficiency by as much as 15%. Implementing these best practices not only helps in maintaining optimal performance but also contributes to sustainability by reducing energy consumption and material waste. As industries continue to evolve, integrating these maintenance strategies will ensure that rubber belt traction machines remain a cornerstone of operational excellence.

The comparative analysis of rubber belt traction machines and traditional conveyor systems reveals significant advancements in industrial efficiency. Rubber belt traction machines have emerged as a revolutionary alternative, particularly in sectors requiring high precision and flexibility. While traditional conveyor systems often exhibit limitations in speed and maintenance costs, rubber belt traction machines leverage improved traction and streamlined designs, enhancing material handling capabilities across various industries.

Recent developments in material handling technologies, such as pneumatic conveying systems, further underscore the transition toward more efficient operational methodologies. These advancements allow for the transport of materials using air flow, reducing the energy required compared to conventional systems. The integration of high-tech solutions, including magnetic drive technology, suggests a shift towards versatile and sustainable manufacturing practices. As industries continue to embrace automation and smart manufacturing, rubber belt traction solutions stand out as essential components for future efficiency and productivity gains.

| Criteria | Rubber Belt Traction Machines | Traditional Conveyor Systems |

|---|---|---|

| Efficiency | Up to 30% more efficient | Standard efficiency |

| Maintenance Frequency | Lower - biannual inspections | Higher - monthly maintenance |

| Operational Noise | Quieter operations | Noisy operations |

| Load Handling Capability | Higher load capacity | Standard load capacity |

| Energy Consumption | 10-20% less energy usage | Standard energy usage |

The advancement of rubber belt technology is set to significantly impact various industrial sectors, enhancing both efficiency and productivity. According to a report by MarketsandMarkets, the global market for conveyor belts is projected to grow from USD 4.29 billion in 2020 to USD 5.59 billion by 2025, at a CAGR of 5.4%. This growth is driven by innovations in rubber composition and design, which have improved traction and durability, making these belts suitable for a wider range of applications, from heavy manufacturing to food processing.

Emerging technologies, such as the integration of smart sensors and IoT capabilities, are also redefining rubber belt traction machines. The ability to monitor belt performance in real-time leads to predictive maintenance, reducing downtime and maintenance costs. A study from Research and Markets highlighted that incorporating such technologies could reduce operational costs by up to 30% for manufacturers. As industries continue to embrace sustainability, advancements in eco-friendly rubber materials promise to deliver not only performance but also a reduced environmental footprint, aligning with global sustainability goals.