In the fast-paced world of manufacturing, efficiency is key to maintaining a competitive edge. One of the most effective ways to optimize your production line is by incorporating a Conveyor Belt Slitting Machine. This specialized equipment streamlines the process of cutting conveyor belts to custom widths, ensuring that your production line operates smoothly and meets specific operational requirements. By utilizing a Conveyor Belt Slitting Machine, manufacturers can reduce material waste, improve product quality, and enhance workflow efficiency. Throughout this guide, we will explore various strategies and best practices for integrating this vital machinery into your production line, helping you harness its full potential to achieve operational excellence and drive productivity to new heights.

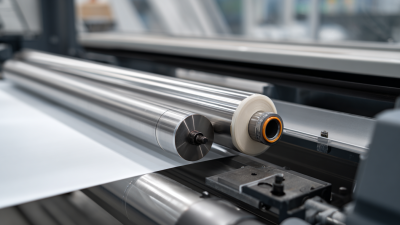

Conveyor belt slitting machines are essential tools in modern production lines, allowing manufacturers to optimize their processes with precision and efficiency. These machines enable the customization of conveyor belts to specific widths and lengths, adapting to diverse production needs. Understanding the basics of these machines is crucial for integrating them effectively into any production setup. By leveraging automated technology, manufacturers can achieve seamless transitions between cutting operations, minimizing downtime and maximizing productivity.

Conveyor belt slitting machines are essential tools in modern production lines, allowing manufacturers to optimize their processes with precision and efficiency. These machines enable the customization of conveyor belts to specific widths and lengths, adapting to diverse production needs. Understanding the basics of these machines is crucial for integrating them effectively into any production setup. By leveraging automated technology, manufacturers can achieve seamless transitions between cutting operations, minimizing downtime and maximizing productivity.

Recent advancements in machinery highlight the trend towards automation and smart technology in the manufacturing sector. For instance, various industries are adopting solutions that enable real-time monitoring and adjustments, which can significantly enhance the performance of conveyor belt slitting machines. The implementation of automated cutting processes not only streamlines production but also aligns with the broader movement towards Industry 4.0, where interconnected systems elevate operational efficiency. By prioritizing the integration of these innovative technologies, businesses can attain higher throughput and reduced labor costs, ultimately strengthening their competitive edge in the market.

When it comes to optimizing your production line, integrating conveyor belt slitting machines can significantly enhance efficiency and streamline operations. One of the key benefits of using these machines is their ability to deliver precise cuts, ensuring that material wastage is minimized. This precision not only leads to cost savings but also improves the overall quality of the end products. With accurate slitting, manufacturers can meet exact specifications, which is crucial in industries such as packaging and textiles.

Tips for choosing the right slitting machine include assessing the types of materials you'll be working with and ensuring the machine can handle their specific properties. Additionally, consider the speed and automation capabilities of the machine to keep up with your production demands. Regular maintenance is also vital; keeping blades sharp and machinery clean can prevent production downtime and ensure consistent performance.

Implementing conveyor belt slitting machines enhances not just productivity but also safety in the workplace. By automating the cutting process, human error is reduced, and workers can focus on other critical tasks, maximizing the flow of production. Ensure that your team is well-trained on the use of these machines to further enhance operational efficiency and safety standards.

Integrating slitting machines into existing workflows can significantly enhance efficiency in production lines. To achieve this, it’s essential to first assess the current layout and workflow dynamics. Identify the areas where slitting machines can be most beneficial, such as near the loading and unloading zones. This strategic placement minimizes downtime and maximizes productivity. In addition, ensure that all staff are adequately trained to operate the new machinery, as familiarity with the equipment can greatly reduce errors and increase throughput.

Another best practice is to implement a continuous feedback loop among operators and maintenance teams. This allows for ongoing adjustments and improvements in the workflow. Regular meetings to discuss challenges and solutions can foster a collaborative environment conducive to optimization. Moreover, consider integrating automation where feasible, as it can enhance precision and reduce labor costs while seamlessly working alongside slitting machines. By aligning the goals of both operators and machinery, manufacturers can create a more streamlined and efficient production line.

| Dimension | Details |

|---|---|

| Machine Type | Horizontal Slitting Machine |

| Cutting Width | 1-4 meters |

| Max Speed | 120 meters/minute |

| Material Type | Plastic, Paper, Textile |

| Energy Consumption | 5kW/h |

| Maintenance Frequency | Every 200 hours of operation |

| Operator Training | Required |

| Integration Options | Automation, Manual Feeding |

| Average ROI | 12-18 months |

To ensure optimal performance of conveyor belt slitting machines, regular maintenance is crucial. Cleanliness is the first step; debris and scraps can accumulate and impede the machine's effectiveness. Daily inspections of the cutting blades for wear or damage are essential, as dull or nicked blades can compromise cut quality, leading to waste and increased downtime. Lubricating moving parts according to the manufacturer’s specifications not only extends the life of the machine but also enhances its operational efficiency.

Another vital maintenance tip involves monitoring the tension of the conveyor belt. Incorrect tension can lead to uneven slicing and additional strain on the machine's motor, resulting in premature wear. Operators should be trained to adjust belt tension as needed and routinely check for signs of fraying or damage. Additionally, keeping a detailed maintenance log will help track performance issues, allowing for predictive maintenance actions that can avert costly breakdowns, ultimately ensuring the smooth operation of the production line.

In recent years, the implementation of slitting machines in manufacturing has proven to be a game-changer, as highlighted by various case studies across different industries. Companies have reported significant improvements in efficiency and precision by integrating advanced slitting technologies into their production lines. These machines not only enhance the quality of the finished products but also reduce waste, ultimately leading to a more sustainable manufacturing process.

For instance, one notable case involved a company that specialized in electronic components, which successfully adopted a precision slitting machine. This upgrade allowed them to achieve high-level accuracy in their processes, significantly cutting down the production time and increasing output. Such advancements illustrate a broader trend in manufacturing, where organizations recognize the importance of investing in cutting-edge equipment to drive innovation and maintain competitiveness in an evolving market.