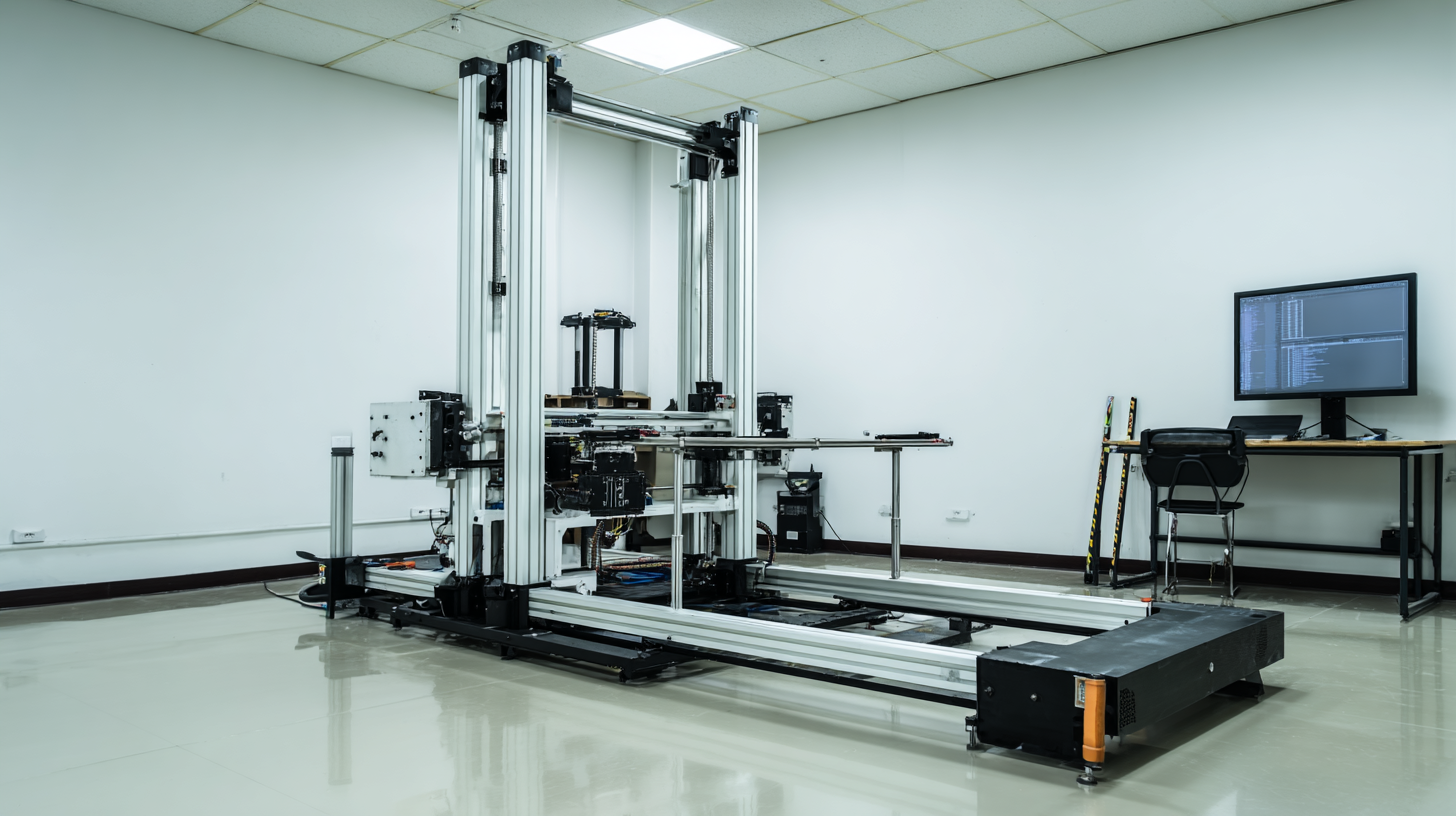

In today's fast-paced business environment, maximizing efficiency is crucial for staying competitive and meeting customer demands. One of the essential tools that can significantly enhance operational productivity is the Strap Cutter Machine. This advanced equipment not only streamlines the packaging process but also ensures precision and safety during material handling. By automating the cutting of straps, businesses can reduce labor costs, minimize waste, and improve the speed of their operations. In this guide, we will explore effective strategies to optimize the use of the Strap Cutter Machine, focusing on integration into existing workflows, maintenance practices, and tips for maximizing output. Whether you are managing a manufacturing facility or a packaging operation, understanding how to leverage this machine can lead to substantial gains in efficiency and overall business performance.

Using a strap cutter machine can significantly enhance the efficiency of your operations, particularly in industries that require packaging and securing goods. One of the main advantages is the time saved during the strapping process. Traditional manual cutting can be labor-intensive and prone to errors. A strap cutter machine streams the workflow by automating this task, leading to increased productivity and reduced labor costs. Additionally, these machines often provide a cleaner cut, which can prevent fraying and ensure the integrity of the strap used.

Tips: To maximize the benefits of a strap cutter machine, consider investing in a model with adjustable settings for different strap sizes. This flexibility allows you to accommodate varying requirements in your business, ensuring you’re always prepared for any project. Regular maintenance is also crucial; keeping the blades sharp and the machine clean will prolong its lifespan and maintain optimal performance.

Another advantage lies in safety. Manual cutting can pose a risk of injury, particularly in fast-paced environments. Strap cutter machines are designed with safety features that protect operators, which not only keeps your team safe but also reduces potential downtime due to accidents. Investing in user training can further enhance these safety measures, ensuring that all personnel operate the machines effectively.

When selecting a strap cutter machine for your business, it's vital to focus on its key features to optimize efficiency. First and foremost, consider the machine's cutting speed and accuracy. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), machines that offer cutting speeds of 100 straps per minute or more can significantly enhance operational efficiency. This is essential for businesses that handle large volumes of packaging materials daily.

Another important feature is the machine's adaptability to various strap sizes and materials. A versatile cutter can save time and labor costs, as it minimizes the need for multiple machines. According to a study by Smithers Pira, companies that invest in adaptable machinery experience a 30% reduction in operational downtime. Pay attention to the machine's ease of use and maintenance, as these factors can impact long-term efficiency and employee productivity.

**Tips:** Always prioritize machines with user-friendly interfaces and low maintenance needs. Consider conducting a cost-benefit analysis to assess how the specific features of a strap cutter machine align with your business goals, ensuring you make a well-informed investment. Look for customer reviews or case studies that highlight real-world applications and the efficiency gains experienced by other companies in your industry.

| Feature | Description | Importance Level | Example Products |

|---|---|---|---|

| Cutting Speed | Rate at which the machine can cut straps. | High | Model A, Model B |

| Ease of Use | User-friendly interface and operation. | Medium | Model C, Model D |

| Safety Features | Includes guards and automatic shut-off systems. | High | Model E, Model F |

| Portability | Weight and ease of transport for different work sites. | Low | Model G, Model H |

| Durability | Material quality and machine lifespan. | High | Model I, Model J |

| Maintenance Requirements | Frequency and type of maintenance needed. | Medium | Model K, Model L |

Integrating a strap cutter machine into your workflow can significantly enhance operational efficiency. Industry reports show that automating the strapping process can reduce labor costs by up to 30% while increasing productivity by at least 25%. To start, assess your current workflow and identify bottlenecks that the strap cutter machine can alleviate. This may involve evaluating the types of materials being used and the existing manual processes that are slowing down operations. A study from the Packaging Machinery Manufacturers Institute (PMMI) indicates that simplified workflows lead to a 20% reduction in operational errors, thereby improving overall efficiency.

The next step is to train your team on the new equipment. Proper training ensures that employees are familiar with the machine’s features and capabilities, which can lead to smoother operations and fewer interruptions. According to a report by the National Institute of Standards and Technology (NIST), effective training programs can boost equipment utilization rates by 40%. Additionally, consider periodic evaluations to gather feedback on the machine's performance, adjusting processes as necessary to ensure optimal integration into your daily tasks. Implementing these steps will not only streamline your operations but also contribute to a more efficient and productive business model.

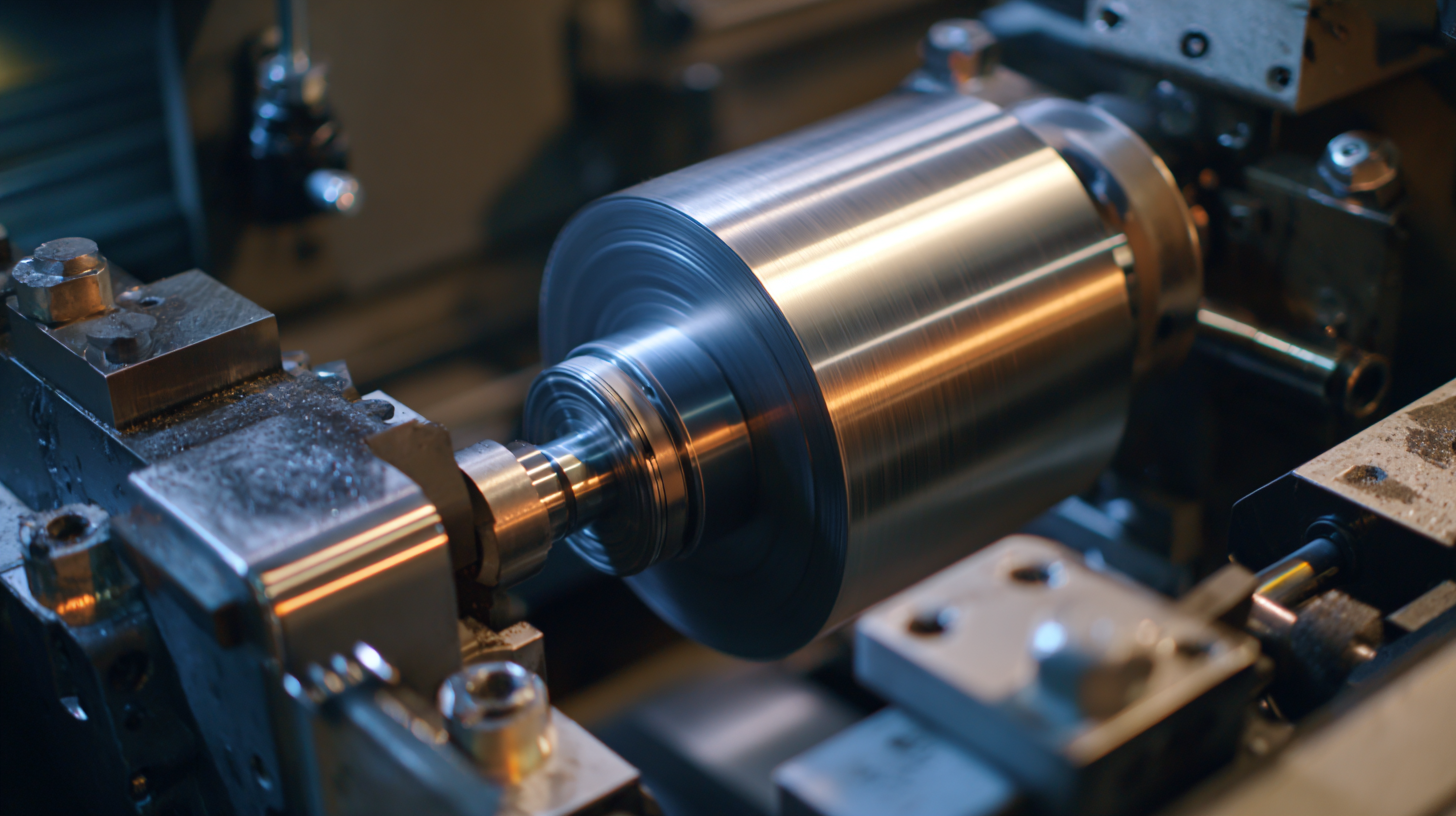

Maintaining your strap cutter machine is vital for ensuring its longevity and optimal performance in your business operations. Regular maintenance not only keeps the machine running smoothly but also enhances its capacity to handle various tasks efficiently. One key aspect of maintenance is keeping the rollers clean and lubricated. This practice can prevent the build-up of debris, which can hinder the machine's functionality and lead to premature wear.

Another important tip is to regularly inspect the blades for sharpness and damage. Dull or damaged blades can lead to inefficient cuts and may put extra strain on the machine. Replacing blades when needed can significantly extend the life of the strap cutter machine. Additionally, operators should monitor the machine for odd noises or vibrations that may indicate a need for repair or adjustment, as catching these issues early can prevent costly breakdowns.

Lastly, it’s essential to follow the manufacturer’s guidelines for maintenance schedules and practices. Keeping abreast of any new features or updates can also enhance your machine's performance. By prioritizing these maintenance practices, business owners can ensure that their strap cutter machines operate efficiently and retain optimal performance over time.

Training your staff effectively on the use of strap cutter machines is pivotal for maximizing operational efficiency. A well-trained workforce not only enhances productivity but also reduces the risk of workplace injuries. According to a study published in the Journal of Occupational Safety, companies that invested in employee training programs saw a 35% decrease in accidents. This statistic underscores the importance of educating staff on the correct and safe operation of such machinery.

Additionally, equipping your team with comprehensive knowledge of the machine's features can lead to significant time savings. For instance, the Industrial Equipment Efficiency Report highlights that businesses using strap cutter machines with trained personnel could reduce material waste by up to 15% within six months of training implementation. By understanding the nuances of the equipment, operators can make precise cuts and perform maintenance correctly, which contributes to a more streamlined production process. Thus, investing in training not only boosts morale but also aligns with business goals of efficiency and sustainability.