In today’s fast-paced manufacturing environment, optimizing processes is crucial for maintaining competitiveness and profitability. A recent report by Smithers Pira highlights that the global market for slitter technology, including Conveyor Belt Slitters, is expected to grow at a CAGR of 4.5% through 2025, driven by the increasing demand for precision cutting and material efficiencies.

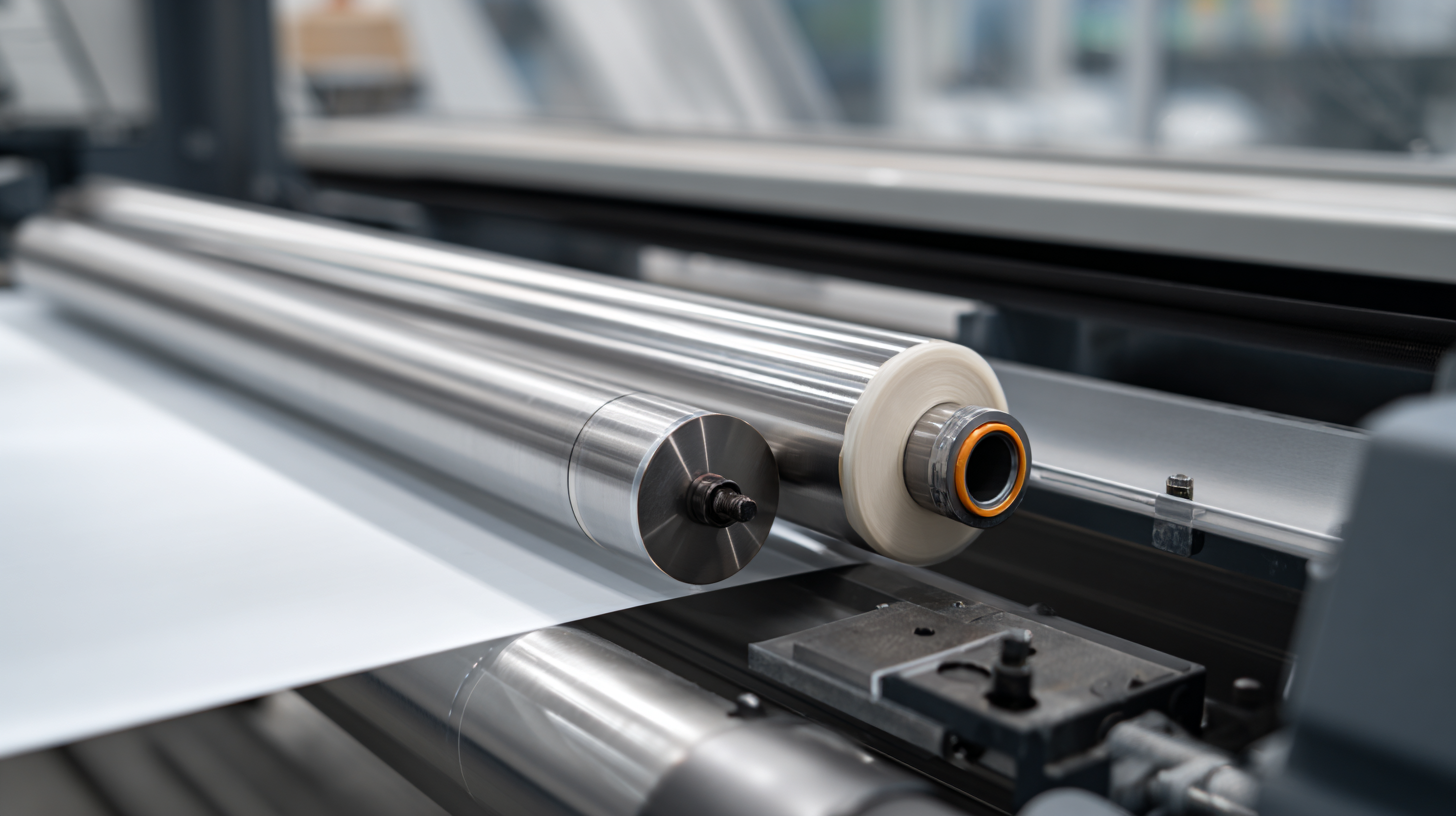

Conveyor Belt Slitters are essential tools in various industries, ensuring that materials are processed quickly and accurately, which in turn reduces waste and enhances productivity. By implementing top strategies for maximizing efficiency with these machines, manufacturing operations can significantly lower their operational costs while improving output quality.

This blog will explore best practices and innovative approaches to leverage Conveyor Belt Slitters effectively, enabling manufacturers to stay ahead in a competitive landscape.

Implementing conveyor belt slitters in manufacturing processes offers numerous benefits that can significantly enhance productivity and operational efficiency. These machines enable precise cutting of materials, ensuring consistency and reducing waste. With the ability to process different widths and lengths, manufacturers can quickly adapt to varying project requirements without the need for extensive downtime. This flexibility not only streamlines production but also helps in maintaining a competitive edge.

To maximize the benefits of conveyor belt slitters, consider these tips: First, regularly maintain the equipment to prevent breakdowns and ensure optimal performance. A well-maintained slitter will consistently deliver high-quality cuts, reducing the likelihood of costly errors. Second, invest in training for your operators so they can effectively utilize the machinery, which will enhance both speed and accuracy in the cutting process.

Additionally, integrating advanced control systems can provide real-time monitoring of the slitting process, allowing for immediate adjustments. This ensures that any potential issues are addressed swiftly, safeguarding production timelines and materials. By embracing these strategies, manufacturers can fully leverage the capabilities of conveyor belt slitters to boost efficiency and drive successful outcomes in their operations.

In the manufacturing sector, traditional conveyor belt slitters have long been a staple for cutting materials efficiently. However, with evolving technologies and the increasing demand for enhanced production speeds, innovative alternatives are redefining how we approach this aspect of manufacturing. Recent data from the Manufacturing Technology Nerds indicate that adopting advanced slitters can improve production efficiency by up to 30%, significantly reducing downtime and wastage.

One of the most promising alternatives includes automated laser cutting systems. According to a report from the International Journal of Advanced Manufacturing Technology, laser cut systems not only provide precision cuts but also operate at a 50% faster rate compared to conventional methods. This is particularly advantageous in high-speed environments, allowing for smoother transitions in the workflow. Additionally, the integration of smart technologies, such as IoT-enabled monitoring systems, facilitates real-time adjustments, leading to a marked improvement in overall production rates.

As businesses seek to optimize operations, investing in innovative slitting technologies is becoming critical. Reports suggest that manufacturers who implement these systems see a reduction in labor costs and an improvement in safety standards, resulting in a more streamlined production process. Embracing these innovative alternatives not only enhances efficiency but also positions companies as leaders in the highly competitive manufacturing landscape.

When considering alternatives to traditional conveyor belt slitters, several key features can significantly enhance efficiency and productivity in manufacturing processes. One important aspect is the slitting precision; advanced models can achieve tolerances as tight as ±0.5 mm. According to a report by the Manufacturing Technology Association, such precision not only minimizes material waste but also reduces the need for rework, ultimately leading to cost savings of up to 15% per project.

Another crucial feature is the speed of operation. Modern conveyor belt slitters can operate at speeds exceeding 300 meters per minute, allowing manufacturers to meet high-demand cycles without compromising quality. A study by the International Journal of Production Research highlights that increasing operational speed can boost output by nearly 25%, which is vital for companies aiming to optimize their production schedules amid fluctuating market demands.

Additionally, ergonomic design plays a significant role in worker safety and efficiency. Systems that incorporate adjustable height settings and intuitive controls can lead to a decrease in operator fatigue, as reported by the Occupational Safety and Health Administration. This improvement can further increase productivity by reducing downtime associated with worker injuries and enhancing overall workflow in manufacturing environments.

| Feature | Description | Benefit | Efficiency Gain (%) |

|---|---|---|---|

| Automatic Adjustments | Features sensors for real-time adjustments | Reduces manual intervention and downtime | 20% |

| Energy Efficiency | Uses lower power motors and innovative designs | Lower energy costs and environmental impact | 15% |

| Modular Design | Easily customizable parts for different applications | Increased versatility and reduced downtime | 25% |

| User-Friendly Interface | Intuitive controls for easier operation | Reduces training time for operators | 30% |

| Advanced Safety Features | Incorporates emergency stops and protective shields | Increases worker safety and compliance | 10% |

In the competitive landscape of manufacturing, optimizing efficiency is crucial. Companies are increasingly turning to innovative alternatives to traditional conveyor belt slitters, seeking to enhance operational productivity. Among the success stories, a leading packaging firm implemented a state-of-the-art slitter that not only improved material handling but also reduced downtime by 30%. This shift enabled them to streamline their production processes, proving that investing in modern technology can yield significant returns.

In the competitive landscape of manufacturing, optimizing efficiency is crucial. Companies are increasingly turning to innovative alternatives to traditional conveyor belt slitters, seeking to enhance operational productivity. Among the success stories, a leading packaging firm implemented a state-of-the-art slitter that not only improved material handling but also reduced downtime by 30%. This shift enabled them to streamline their production processes, proving that investing in modern technology can yield significant returns.

Another manufacturer in the automotive sector experienced a transformation by incorporating modular slitter systems. These adaptable solutions allowed for quicker adjustments and versatile production capabilities, ultimately cutting lead times in half. By sharing these success stories, it's evident that organizations willing to embrace new slitting technologies can not only solve existing inefficiencies but also position themselves as leaders in a rapidly evolving industry. Such innovations highlight the importance of staying ahead of the curve in manufacturing, ensuring that businesses can meet the demands of today’s market.

As the manufacturing landscape continues to evolve, the future trends in conveyor belt slitting technologies promise to significantly impact efficiency and productivity. Advanced automation and smart technology integration are at the forefront of these innovations. Manufacturers are increasingly utilizing AI-driven systems that optimize cutting processes, reduce waste, and shorten production times. This shift not only enhances operational efficiency but also lowers costs in the long run.

To maximize efficiency with conveyor belt slitters, companies should invest in training personnel on the latest technologies. Understanding how to operate and maintain automated systems can greatly reduce downtime and improve overall output. Additionally, regularly updating equipment to include the latest software can streamline processes, making it easier to monitor performance and implement improvements.

Another essential tip is to embrace predictive maintenance. By utilizing IoT sensors and data analytics, manufacturers can anticipate potential failures before they occur, ensuring that slitting operations run smoothly. This proactive approach minimizes disruption and extends the lifespan of equipment, ultimately contributing to a more efficient manufacturing process. As conveyor belt slitting technologies advance, staying informed and adaptable will be key to leveraging their full potential.