In today’s fast-paced manufacturing environment, optimizing operational efficiency is paramount, especially for industries relying on Rubber Belt Rewinder Machines. According to a recent market analysis by Industry Research, the demand for advanced rewinding technologies has grown by approximately 15% year-over-year, highlighting the essential role these machines play in enhancing productivity and reducing waste. The Rubber Belt Rewinder Machine not only streamlines the processing of rubber materials but also minimizes downtime and operational costs, thereby contributing to a more sustainable production model. As manufacturers seek to improve their competitive edge, understanding and implementing top strategies for maximizing the efficiency of these machines has never been more critical.

This ultimate guide will delve into effective approaches that can help businesses leverage the full potential of Rubber Belt Rewinder Machines, ultimately driving profitability and operational excellence.

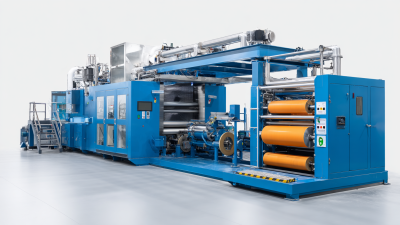

Rubber belt rewinder machines have become essential tools in various industries, significantly enhancing productivity through efficiency and reliability. These machines not only streamline the process of rewinding rubber belts but also minimize downtime, leading to higher output levels. Employing these machines can lead to substantial cost savings by reducing material waste and labor hours.

One effective tip for maximizing productivity with rubber belt rewinder machines is to maintain regular maintenance schedules. Ensuring that machines are regularly checked and serviced can prevent unexpected breakdowns and prolong their lifespan. Furthermore, training operators to use the machines effectively can increase their proficiency, leading to quicker setups and smoother operation.

Another strategy is to invest in technology that enhances automation. Integrating advanced controls can optimize the rewinding process, allowing for precise adjustments and real-time monitoring. This not only accelerates production rates but also ensures consistent quality, catering to the diverse needs of the manufacturing process.

This chart illustrates the impact of rubber belt rewinder machines on production efficiency in terms of time saved, waste reduced, and overall productivity improvement.

When selecting a rubber belt rewinder machine, several key features can significantly influence efficiency and performance. First and foremost, consider the machine's speed and throughput capacity. A higher speed not only reduces downtime but also increases productivity, enabling you to manage larger workloads without compromising quality. Look for models equipped with variable speed settings to tailor the operation according to your specific needs.

Another important factor is the adjustability and ease of use of the machine. A user-friendly interface and easy adjustment features can help operators minimize setup time and streamline the rewinding process. Machines that allow quick and accurate changes to belt sizes and tension settings will ensure consistent results and reduce the risk of operational errors.

Tips for maximizing performance include regularly maintaining the equipment to prevent unexpected breakdowns, ensuring that all parts are lubricated and in good working condition. Additionally, proper training for operators can significantly enhance efficiency; knowledgeable staff can react swiftly to challenges and make informed adjustments, leading to smoother operations. By focusing on these essential features and tips, you can optimize the performance of your rubber belt rewinder machine.

When it comes to rubber belt rewinding, industries often face the decision between manual and automated solutions. A recent industry report indicates that automated rubber belt rewinders can increase production efficiency by up to 30% compared to their manual counterparts. This is largely due to reduced operator intervention, minimizing human errors, and streamlining the workflow. Manual rewinders, while cost-effective initially, may lead to higher operational costs in the long run due to slower processing times and increased labor reliance.

**Tip:** To enhance efficiency, organizations should evaluate their production volume and consider investing in automated systems that align with their workload. Though the upfront costs might be higher, the long-term ROI through improved efficiency can be substantial.

Furthermore, automated systems often come equipped with smart technology that allows for real-time monitoring and adjustments. According to a study published by the Manufacturing Technology Institute, these systems can minimize material waste by as much as 20%. This not only saves on raw material costs but also supports sustainability initiatives within the industry.

**Tip:** Regular maintenance and training for staff on automated systems can further amplify the benefits gained from these technologies, ensuring peak performance and durability.

When considering the implementation of rubber belt rewinder machines, evaluating their long-term returns on investment (ROI) is crucial for businesses striving for cost-effectiveness. According to a recent report by IBISWorld, companies in the manufacturing sector that invest in automated machinery, such as rewinder machines, have seen productivity increases of up to 30%. This surge in efficiency not only streamlines operations but also reduces labor costs significantly over time.

Moreover, the upfront costs of rubber belt rewinder machines are often offset by the decrease in waste and downtime. For instance, a study by the National Association of Manufacturers indicates that improved machinery maintenance and reduced processing time can save companies up to $200,000 annually. These savings, combined with the enhanced product quality from consistent rewinding processes, demonstrate that investing in high-quality rubber belt rewinder machines can yield compelling financial returns in the long term. By prioritizing such investments, businesses can ensure they remain competitive and resilient in an ever-evolving marketplace.

| Strategy | Initial Investment ($) | Annual Operating Cost ($) | Lifetime (Years) | Estimated Total Returns ($) | ROI (%) |

|---|---|---|---|---|---|

| Regular Maintenance | 15,000 | 2,000 | 10 | 80,000 | 350% |

| Operator Training | 10,000 | 1,500 | 8 | 60,000 | 500% |

| Upgrading Equipment | 25,000 | 3,000 | 12 | 120,000 | 380% |

| Process Optimization | 5,000 | 1,000 | 5 | 30,000 | 500% |

| Energy Efficiency Improvements | 8,000 | 800 | 7 | 40,000 | 400% |

To ensure optimal performance of rubber belt rewinder machines, regular maintenance is essential. According to a report by the International Rubber Study Group, companies that implement rigorous maintenance routines see a 20% increase in the longevity of their equipment. Regular inspection of components such as belts, rollers, and drive systems can prevent unexpected downtime and extend the machine's lifespan. Key maintenance activities include cleaning, lubrication, and tension adjustments, which can contribute significantly to operational efficiency.

Additionally, it is crucial to monitor the environmental conditions under which the machines operate. A study published by the American Society for Quality indicates that maintaining stable temperature and humidity levels can reduce wear and tear on rubber belts by up to 30%. Ensuring that the machines are operated within the manufacturer-recommended parameters not only helps maintain performance but also leads to better energy efficiency. By integrating these maintenance protocols, companies can maximize efficiency and minimize costs associated with repairs and replacements.