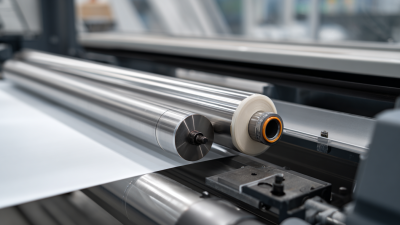

In today's competitive manufacturing landscape, the efficiency of production processes is paramount, and optimizing equipment is a critical aspect of achieving higher productivity levels. Among various tools used in production lines, the Conveyor Belt Slitter plays a vital role in processing materials with precision and speed. According to recent industry reports, companies that invest in efficient machinery like Conveyor Belt Slitters can experience up to a 30% increase in throughput and a significant reduction in material waste.

As industries strive to meet growing demands while minimizing operational costs, understanding how to maximize the efficacy of these slitting machines becomes essential. This guide will explore key strategies to enhance the performance of Conveyor Belt Slitters, ultimately contributing to streamlined production and improved bottom lines.

When it comes to enhancing production efficiency, selecting the right conveyor belt slitter is crucial. Key features such as blade quality, cutting precision, and operational speed can significantly impact the performance of the slitting process. According to a recent industry report by the International Conveyor Belt Manufacturing Association, companies that prioritize high-quality slitting equipment can achieve up to 20% higher throughput rates compared to those using standard machinery. Investing in advanced blade materials can reduce wear and tear, ensuring consistent performance and less downtime.

Tip: Regular maintenance of the slitter blade is essential. A sharp blade can improve cutting accuracy, which leads to lesser material waste and better product quality.

Furthermore, the integration of automated controls is becoming a game-changer. Automated systems allow for precise adjustments during operation, ensuring that slits are uniform and production levels remain high. Data shows that businesses employing automation in their slitting processes can reduce labor costs by approximately 15%, while simultaneously increasing output.

Tip: Consider incorporating real-time monitoring systems to track the performance of your conveyor belt slitter, as this can lead to data-driven decisions for continuous improvement.

In the quest for optimal production using a conveyor belt slitter, understanding the impact of blade quality on slitting efficiency is paramount. High-quality blades ensure precise cutting, which is essential for maintaining consistent slice thickness and preventing material waste. For instance, a study on motorized cassava slicers revealed that specific combinations of speed and blade projection significantly enhance mechanical and chipping efficiency. This underscores the necessity of selecting the appropriate blade specifications for the material being processed.

Tip: When assessing blade quality, consider the material and geometry of the blade, as these factors can influence durability and performance. Investing in high-speed steel or carbide blades can reduce wear and improve cutting efficiency, especially in challenging materials.

Moreover, the operational parameters, such as speed and blade projection depth, play a crucial role in slitting quality. Results from experiments indicate that proper calibration can significantly enhance productivity and slicing accuracy. As industries increasingly turn to advanced machining techniques—including ultrasonic and laser-assisted cutting—prioritizing blade quality becomes essential for remaining competitive.

Tip: Regularly monitoring blade condition and performance can preempt costly downtimes. Implement a maintenance schedule to inspect and replace blades as necessary, ensuring optimal operational efficiency.

| Blade Material | Blade Hardness (HRC) | Slitting Speed (m/min) | Production Efficiency (%) | Maintenance Frequency (weeks) |

|---|---|---|---|---|

| High-Speed Steel | 62 | 25 | 90 | 12 |

| Carbide | 68 | 30 | 95 | 16 |

| Ceramic | 75 | 20 | 88 | 20 |

| Diamond Coated | 85 | 35 | 98 | 25 |

Regular maintenance of your conveyor belt slitter is essential for enhancing efficiency and extending the lifespan of the equipment.

To begin with, establish a routine cleaning schedule to remove debris and dust that can accumulate in the machine. This not only keeps the equipment in optimal condition but also helps prevent unexpected breakdowns.

Inspect the blades regularly, ensuring they are sharp and aligned correctly to avoid excessive wear on the conveyor belt, which can lead to costly repairs and production delays.

In addition to routine cleaning and inspections, lubricating moving parts is critical. Proper lubrication minimizes friction, which can cause wear and tear over time.

Make sure to follow the manufacturer’s recommendations for lubrication intervals and types of lubricant to use.

Lastly, maintain a detailed log of all maintenance activities.

This documentation can help identify patterns in equipment performance and maintenance needs, allowing for more informed decision-making regarding repairs and replacements, ultimately leading to improved production efficiency.

Efficient material flow is crucial for maximizing throughput in production processes involving conveyor belt slitters. One effective approach is to analyze the layout of the conveyor system. By positioning the slitter closer to the subsequent processing stations, you minimize the distance that materials must travel, reducing downtime and potential bottlenecks. Consider utilizing a flow design that allows for optimal retrieval of slitted materials, ensuring that workers can quickly access finished products for packaging or further processing.

Additionally, setting up the conveyor belt slitter for optimal performance involves regular maintenance and adjustments. Ensuring that blades are sharp and properly aligned not only increases cutting precision but also enhances overall efficiency. Scheduling routine checks and calibrations can prevent unforeseen breakdowns and keep production running smoothly. Moreover, implementing a monitoring system to track material flow can provide valuable insights, allowing operators to adjust settings dynamically based on real-time production demands. This data-driven approach ensures that each component of the slitting process is working in harmony, ultimately boosting throughput and production efficiency.

This chart illustrates key efficiency metrics for optimizing your conveyor belt slitter operations. The data points include setup time, downtime, throughput, and material loss percentages, which are crucial for assessing and enhancing production workflows.

Training operators is crucial for ensuring consistent quality and minimizing downtime when using a conveyor belt slitter. A well-trained team can significantly enhance production flow, reducing the likelihood of errors that lead to waste and delays. Investing in regular training sessions will equip operators with the skills needed to troubleshoot common issues and effectively monitor the slitting process.

Training operators is crucial for ensuring consistent quality and minimizing downtime when using a conveyor belt slitter. A well-trained team can significantly enhance production flow, reducing the likelihood of errors that lead to waste and delays. Investing in regular training sessions will equip operators with the skills needed to troubleshoot common issues and effectively monitor the slitting process.

Tip: Implement a structured training program that combines hands-on experience with theoretical knowledge. Encourage operators to familiarize themselves with the machinery, understanding the nuances of blade adjustment and tension settings. This knowledge can help them manage day-to-day operations more efficiently.

Additionally, fostering a culture of continuous learning can lead to improvements in operational procedures. Regularly scheduled refreshers and updates on the latest technologies ensure that operators remain adept and informed.

Tip: Consider pairing experienced operators with new hires for on-the-job mentoring. This partnership not only enhances skills but also builds a sense of teamwork, empowering operators to take ownership of their roles in the production process. With well-trained staff, production will run smoother, resulting in optimal output and reduced downtime.