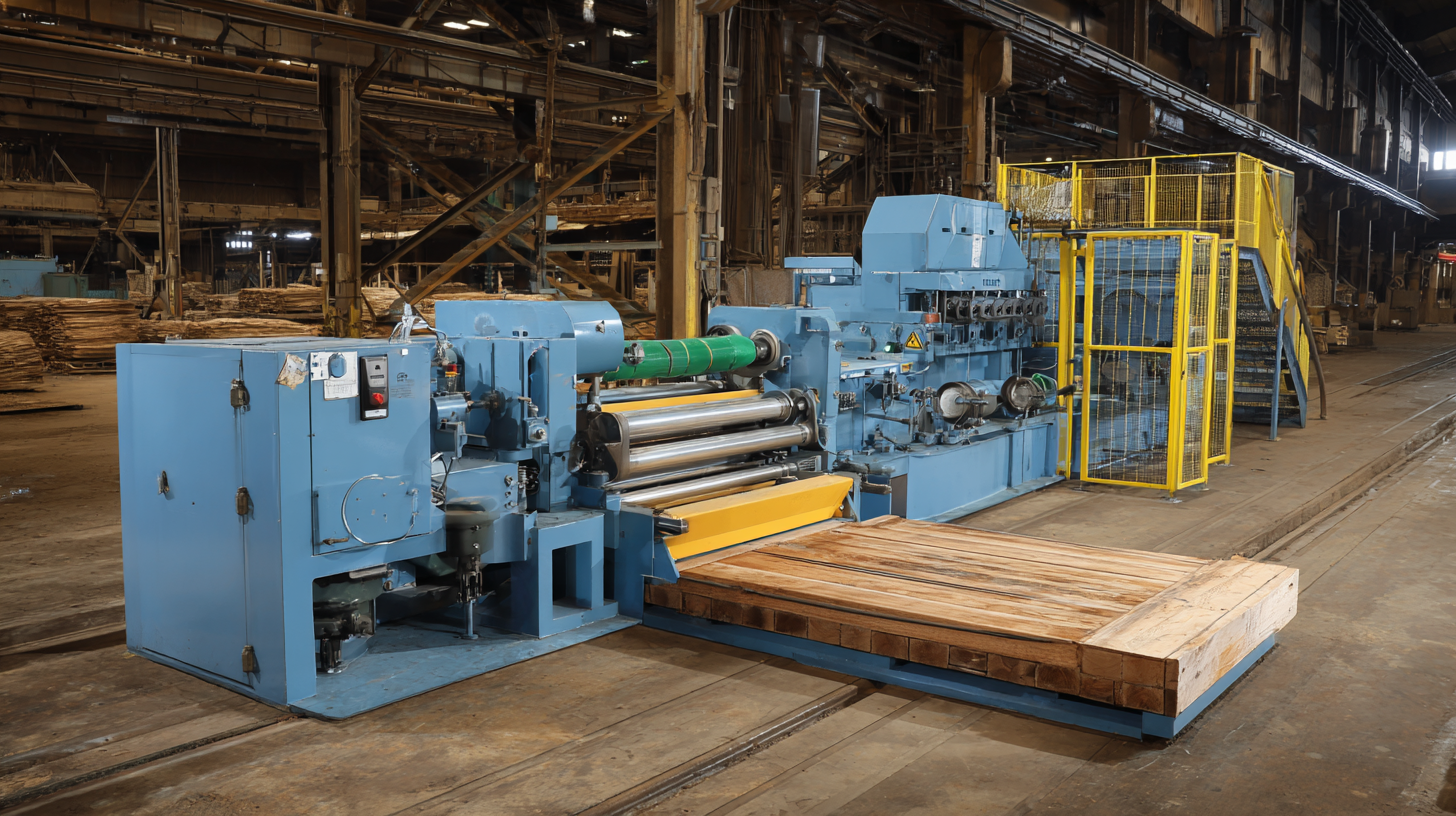

In an era where efficiency is paramount, the use of cutting-edge technology in manufacturing processes has become increasingly vital. Among these technologies, the Rubber Belt Layering Machine stands out as a key player in optimizing production workflows. This machine, designed for the precise layering of rubber materials, not only enhances the quality of the final products but also significantly reduces operational time and costs.

By exploring innovative techniques and best practices associated with the Rubber Belt Layering Machine, manufacturers can unlock a wealth of opportunities for improving their production capabilities.

This article aims to provide a comprehensive guide on how to effectively utilize this machinery, highlighting strategies that maximize efficiency and offer a competitive edge in the ever-evolving manufacturing landscape.

By exploring innovative techniques and best practices associated with the Rubber Belt Layering Machine, manufacturers can unlock a wealth of opportunities for improving their production capabilities.

This article aims to provide a comprehensive guide on how to effectively utilize this machinery, highlighting strategies that maximize efficiency and offer a competitive edge in the ever-evolving manufacturing landscape.

In the rapidly evolving landscape of industrial manufacturing, innovative rubber belt layering techniques are emerging as a pivotal solution for enhancing production rates. Advanced methodologies, particularly those integrating carbon fiber reinforced thermoplastics (CFRTs), promise significant boosts in efficiency due to their lightweight and high-performance capabilities. Recent studies indicate that utilizing CFRTs can lead to production enhancements of up to 30%, making them a game-changer for industries reliant on robust material performance.

Implementing these advanced rubber belt layering techniques not only improves the structural integrity of products but also optimizes the manufacturing process itself. The incorporation of graphene-reinforced elastomers presents a low-cost, effective alternative that can increase the durability of machinery, thereby reducing maintenance costs and downtime. According to industry reports, the shift towards composite materials, like those used in automobile applications, has shown that manufacturers can achieve up to a 20% increase in efficiency while reducing overall material costs.

**Tips:**

1. Consider automating the rubber belt layering process with CNC technology to minimize human error and enhance consistency.

2. Regularly evaluate the materials you use; integrating advanced composites can significantly extend the lifespan and performance of your products.

| Technique | Production Rate (Units/hour) | Efficiency Improvement (%) | Downtime Reduction (%) |

|---|---|---|---|

| Automated Layer Handling | 150 | 30 | 20 |

| Real-time Monitoring System | 180 | 25 | 15 |

| Layer Thickness Optimization | 200 | 35 | 10 |

| Smart Scheduling Software | 220 | 40 | 5 |

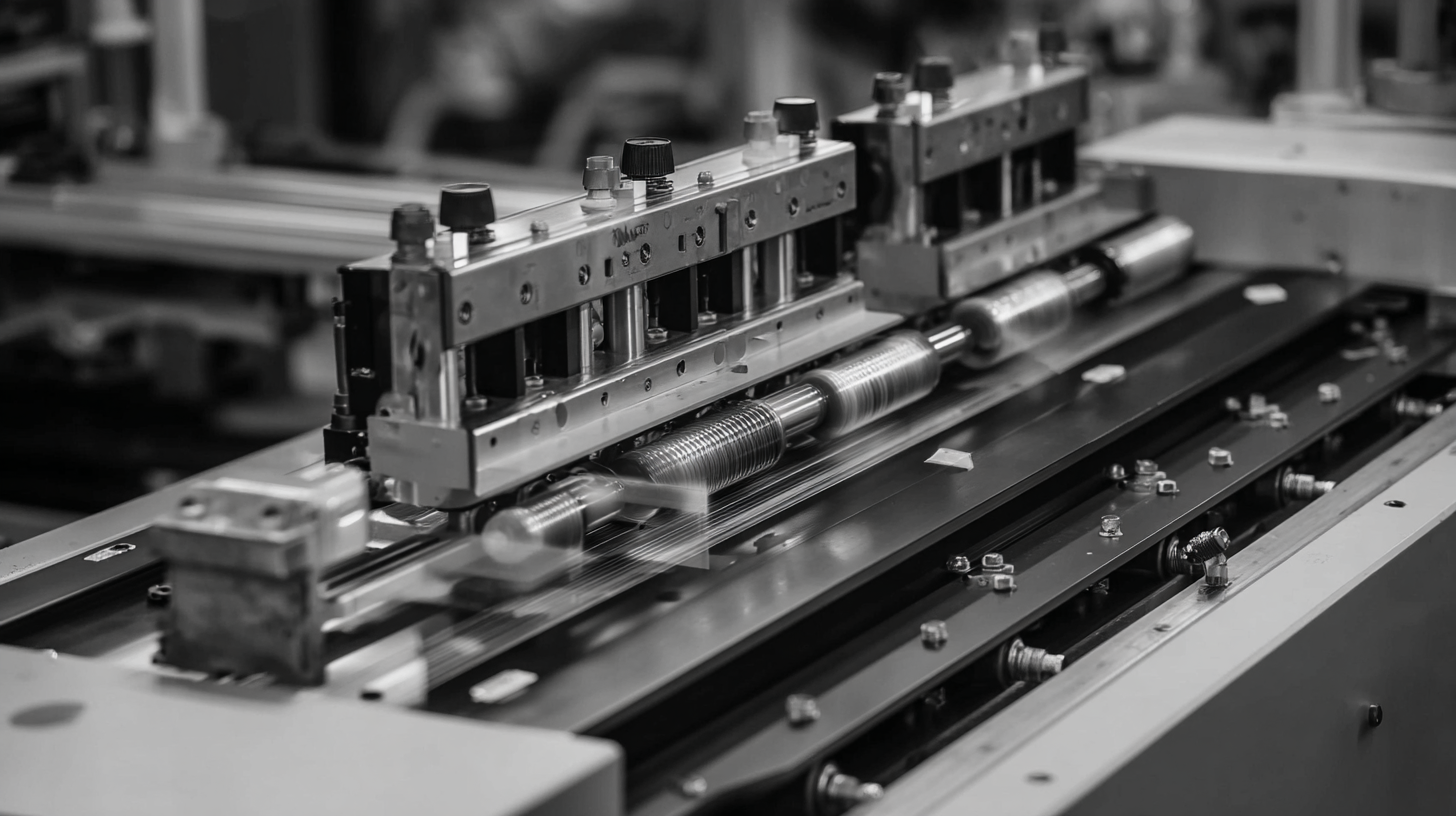

The integration of automation in rubber belt layering operations has revolutionized the manufacturing process, significantly elevating efficiency and output. By employing advanced robotic systems and automated controls, manufacturers can streamline repetitive tasks such as feeding materials, layering, and cutting. This automation reduces the likelihood of human error, enhances precision, and allows for continuous operation, which is vital for meeting increasing production demands. Moreover, real-time monitoring and data analytics enable operators to optimize machine performance and schedule maintenance tasks proactively, thus minimizing downtime.

Implementing smart technology within rubber belt layering machines also facilitates seamless communication between equipment. With Internet of Things (IoT) capabilities, these machines can share performance metrics and operational data, allowing for a more coordinated workflow. Additionally, automated systems can adjust parameters on-the-fly, ensuring that the layering process remains consistent under varying conditions. This adaptability not only maximizes material utilization but also contributes to cost savings across the production line. Overall, the integration of automation in this sector is a key driver for enhancing productivity and maintaining competitiveness in the fast-paced manufacturing landscape.

Upgrading rubber belt layering machines with innovative techniques can significantly enhance efficiency while driving down operational costs. One of the key advantages of implementing state-of-the-art technology is the reduction in material wastage. By utilizing precision layering systems, manufacturers can optimize the use of rubber, ensuring that every inch is used effectively. This not only minimizes production expenses but also contributes to more sustainable manufacturing practices.

Moreover, the integration of advanced automation and real-time monitoring systems plays a crucial role in quantifying cost savings. These upgrades allow for better tracking of production processes and immediately identify areas requiring adjustments. As a result, throughput increases, and downtime decreases, leading to higher overall productivity. On average, companies can expect noticeable reductions in labor and maintenance costs, ultimately boosting profitability. The investment in modern rubber layering machines pays for itself in enhanced performance and significant cost savings.

The integration of real-time data analytics in rubber manufacturing has emerged as a transformative approach to optimizing processes, particularly in the operation of rubber belt layering machines. By continuously collecting and analyzing data from production lines, manufacturers can identify inefficiencies and bottlenecks that impede productivity. This data-driven insight allows for immediate adjustments, enhancing not only the speed of production but also the quality of the final product.

Moreover, the implementation of predictive analytics can deepen the understanding of machine performance and maintenance needs. Using historical data, manufacturers can forecast when a machine is likely to fail or require servicing, thereby minimizing downtime and maximizing operational efficiency. Equally important is the ability to monitor environmental factors, such as temperature and humidity, which play a critical role in rubber processing. By leveraging real-time data, rubber manufacturers can create a more responsive and adaptive production environment, ultimately paving the way for innovations in product development and manufacturing techniques.

The performance of rubber belt layering machines heavily relies on the selection of materials used during the manufacturing process. Different materials can influence the durability, flexibility, and overall functionality of the belts produced. For instance, utilizing high-grade rubber compounds can enhance the longevity of the belts, reducing downtime and maintenance costs. Furthermore, the choice of additives plays a critical role in determining the belts' resistance to environmental factors such as temperature fluctuations and chemical exposure.

In addition to material properties, the thickness and layering techniques applied during production also affect the machine's efficiency. A well-optimized material selection process can lead to improved adhesion between layers, resulting in belts that can withstand higher stress levels during operation. By employing innovative techniques for material testing and evaluation, manufacturers can fine-tune their processes to achieve maximum output and performance. Consequently, a strategic focus on material selection not only boosts the efficiency of rubber belt layering machines but also enhances the quality of the end product, fostering greater customer satisfaction and market competitiveness.