In the ever-evolving landscape of construction and manufacturing, the introduction of advanced tools has become a game-changer for efficiency and precision. One such innovation is the High Speed Air Drill, a tool that not only enhances productivity but also significantly reduces the time spent on drilling tasks. According to John Smith, a respected expert in the field of pneumatic tools and an advocate for modern drilling technologies, “The High Speed Air Drill is revolutionizing the way we approach drilling in various applications, providing unparalleled speed and accuracy that traditional methods simply cannot match.”

This powerful tool harnesses compressed air to maximize drilling speed, making it an invaluable asset for contractors and manufacturers alike. Its benefits extend beyond mere speed; it also minimizes operator fatigue and maximizes versatility, allowing users to tackle a plethora of materials with ease. In projects where time and precision are critical, the High Speed Air Drill stands out as an indispensable resource, driving both innovation and efficiency in the industry. As we explore the capabilities and advantages of this remarkable tool, it becomes clear that investing in a High Speed Air Drill is not just a smart decision—it's a necessity for those who aim to excel in their projects.

A high-speed air drill is a specialized tool designed for enhanced efficiency in various drilling applications, particularly in industries such as aerospace, automotive, and construction. These drills typically operate using compressed air, providing a lightweight and powerful solution for drilling holes in a variety of materials, including metals, plastics, and composites. According to a study by the National Institute of Standards and Technology (NIST), high-speed air drills can achieve rotational speeds of up to 30,000 RPM, significantly outperforming traditional electric drills, which typically max out at around 10,000 RPM. This increased speed allows for quicker material removal and less downtime during projects.

The benefits of high-speed air drills extend beyond mere speed. Their design minimizes torque, which not only reduces operator fatigue but also enhances control during drilling operations. Research from the Society of Manufacturing Engineers indicates that projects using high-speed air drills can see productivity improvements of over 25% compared to those utilizing standard drills. Additionally, the use of air drills contributes to less heat generation, which is crucial in maintaining the integrity of the workpiece, particularly in sensitive applications like aerospace component manufacturing where precision is vital. This combination of speed, efficiency, and reduced thermal impact makes high-speed air drills an invaluable asset in modern manufacturing processes.

A high-speed air drill is a powerful pneumatic tool designed for precision drilling in various materials, from metal to wood. Understanding its components is essential for optimizing its performance and ensuring effective use on projects. At the heart of every high-speed air drill is its motor, typically a turbine or vane type, which allows for rapid rotation and high RPMs (revolutions per minute). According to a report by the Pneumatic Tools Institute, high-speed air drills can reach speeds of up to 30,000 RPM, making them ideal for drilling tasks that require finesse and accuracy.

The drill's body is often ergonomically designed for user comfort and control, which is crucial during extended use. Components such as the chuck securely hold drill bits, which can vary in size and type, offering versatility. Furthermore, advanced air filtration systems are incorporated to prevent debris from entering the motor and affecting performance. Data from the Industrial Maintenance Magazine indicates that using high-quality air drills can reduce downtime due to tool failure by approximately 20%, emphasizing the importance of component quality in maintaining operational efficiency. These intricate details not only showcase the drill's capabilities but also highlight its role in streamlining project timelines and enhancing output quality.

| Component | Description | Benefits |

|---|---|---|

| Motor | Provides the rotational power needed for drilling. | Enables high-speed operation for quicker project completion. |

| Air Compressor | Supplies the compressed air required for operation. | Provides consistent pressure for optimal performance. |

| Chuck | Holds the drill bit securely in place. | Ensures stability during operation for precise drilling. |

| Drill Bit | The component that actually penetrates the material. | Allows for various types of materials to be drilled effectively. |

| Trigger | Controls the airflow and, subsequently, the drill's operation. | Provides user-friendly control for precise drilling tasks. |

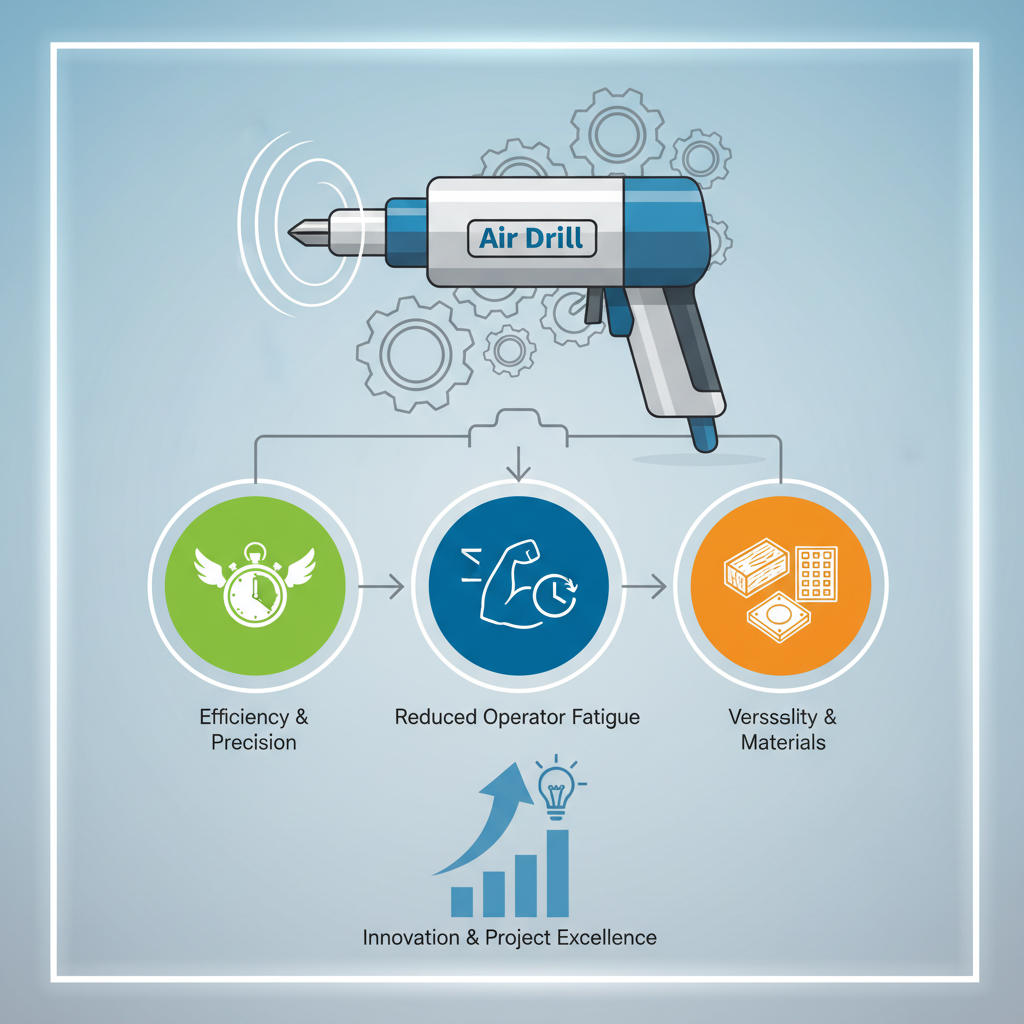

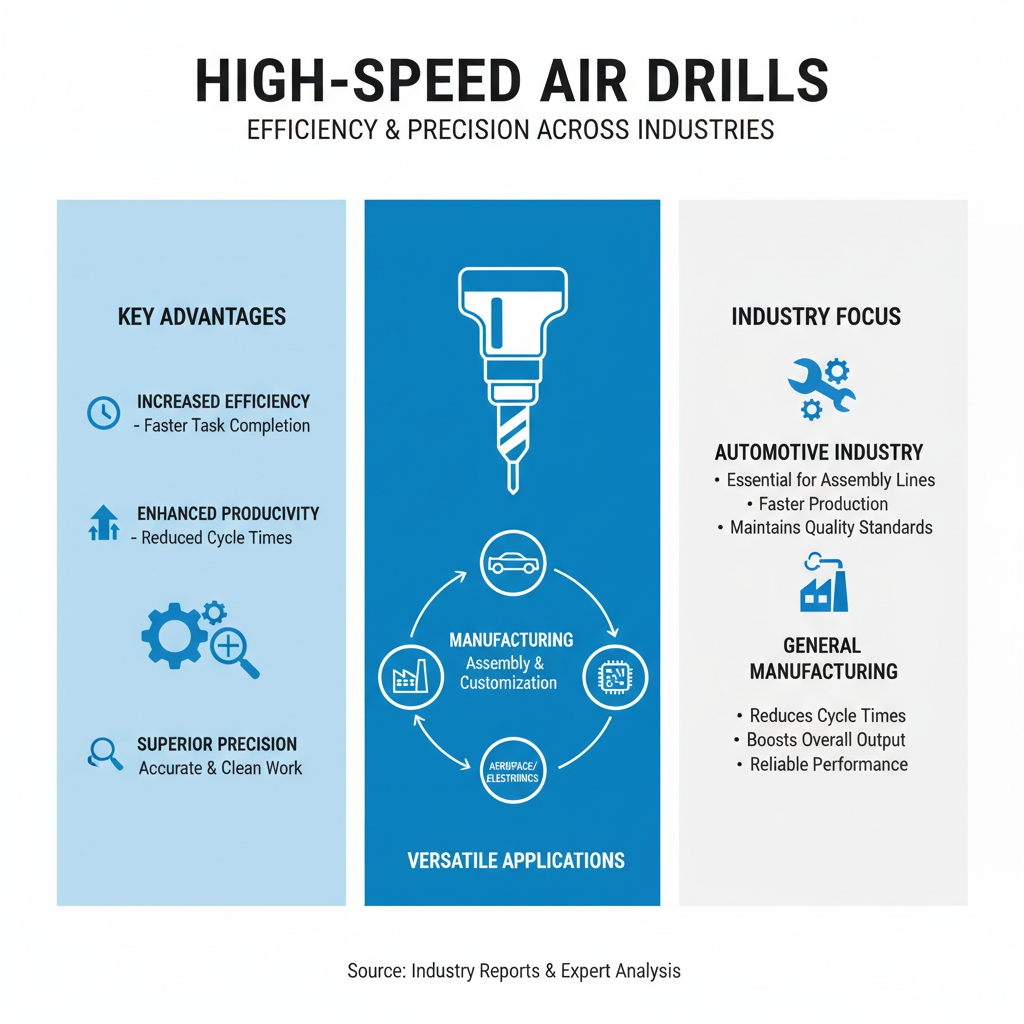

High-speed air drills are increasingly popular tools across various industries due to their efficiency and effectiveness. These drills offer a range of advantages, making them ideal for tasks that require precision and speed. For example, in the automotive industry, high-speed air drills are essential for assembly lines, allowing for faster production while maintaining high standards of quality. In manufacturing, they help to reduce cycle times, enhancing overall productivity.

Tips: When using high-speed air drills, always ensure that you use the appropriate drill bits for the materials you are working with. This not only maximizes efficiency but also extends the life of the drill bits. Regular maintenance checks are crucial to keep the equipment in top condition and to avoid any unexpected downtime.

In the construction sector, these drills are invaluable for tasks such as fastening and boring into various materials. Their lightweight design reduces operator fatigue, making them easier to handle over extended periods. Furthermore, high-speed air drills produce less heat, which minimizes the risk of damage to sensitive components, ensuring that your projects stay on track.

Tips: Always wear the recommended personal protective equipment (PPE) when operating high-speed air drills to ensure safety. Additionally, familiarize yourself with the tool's specifications to optimize its performance based on the specific requirements of each project.

When selecting the right high speed air drill for your project, it's essential to consider several key factors to ensure optimal performance and efficiency. First, evaluate the specifications of the drill, such as its speed, torque, and compatibility with various materials. A higher RPM is typically beneficial for tasks that require precision, like drilling in metal or composite materials. Additionally, consider the drill's air consumption rate; a tool that requires less air pressure can help maintain productivity without overloading your compressor.

Another critical aspect is the ergonomics of the drill. Choose a model that feels comfortable in your hand and is lightweight to reduce fatigue during prolonged use. Features such as adjustable grips and vibration dampening can enhance user comfort. Finally, don’t overlook the reputation and customer reviews of the brand to gauge reliability and performance. By focusing on these factors, you can select a high speed air drill that not only meets the demands of your project but also enhances your overall productivity and work quality.

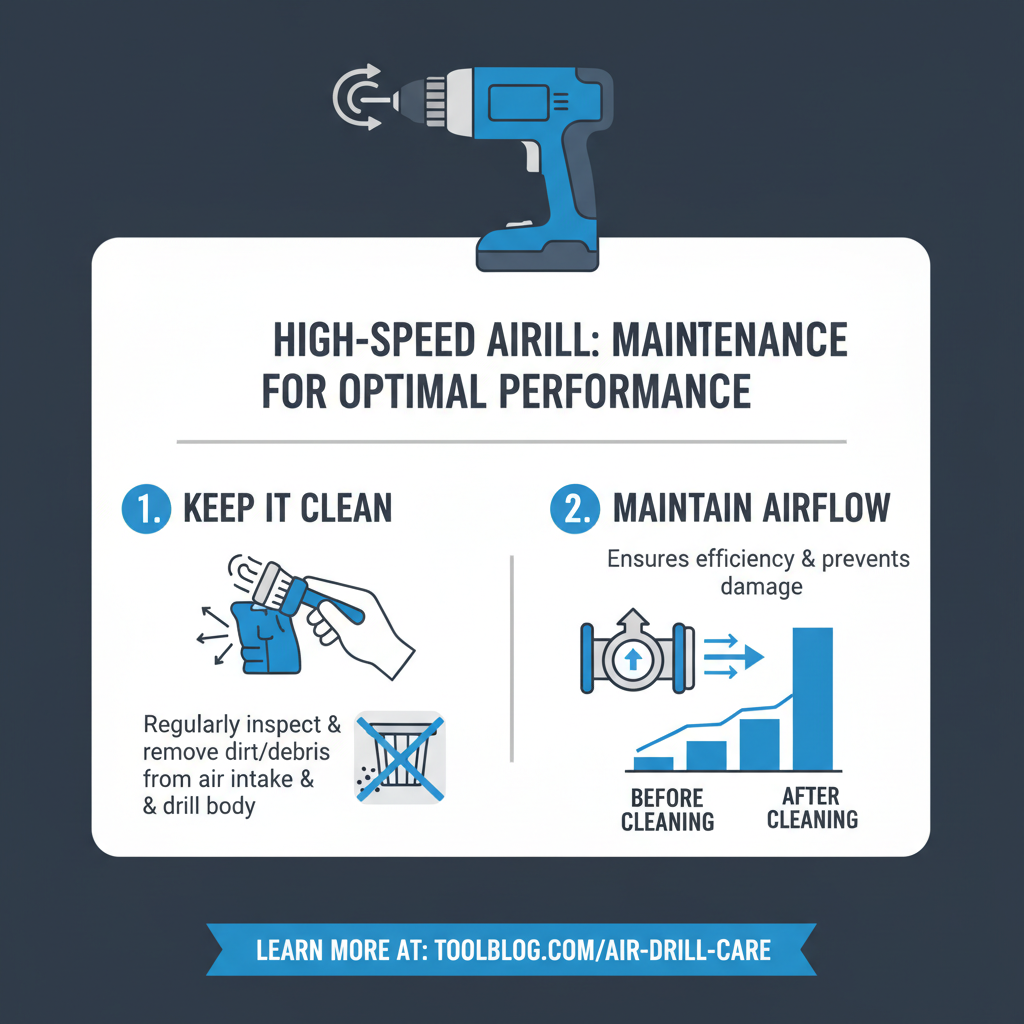

To ensure optimal performance of high-speed air drills, regular maintenance is crucial. First, it is essential to keep the tool clean. Dirt and debris can accumulate in the air intake and the drill itself, leading to reduced efficiency and potential damage. Regularly inspecting and cleaning these areas can help maintain airflow and improve overall functionality.

Another important maintenance tip is to check and replace the air filters regularly. Clogged filters can restrict airflow, causing the drill to work harder and leading to overheating. It is also advisable to lubricate the moving parts according to the manufacturer's recommendations. Proper lubrication minimizes friction, extends the lifespan of the tool, and ensures smooth operation during projects. By implementing these maintenance practices, users can enhance the performance and longevity of their high-speed air drills.