In the fast-paced world of industrial applications, the effectiveness of tools can significantly influence productivity. The High Speed Air Drill has emerged as an essential instrument, renowned for its efficiency and performance in various tasks. According to John Smith, a leading expert in pneumatic tools, “Harnessing the capabilities of a High Speed Air Drill not only enhances precision but also reduces the time required to complete projects." This sentiment captures the essence of what makes these tools indispensable in both professional and DIY settings.

The High Speed Air Drill is engineered to deliver powerful performance with remarkable speed, making it ideal for operations that demand quick and accurate results. Users benefit from its lightweight design and ability to handle multiple materials, which allows for versatility across different applications. As industries continuously seek ways to optimize their workflows, the adoption of High Speed Air Drills provides a clear path to enhancing operational efficiency and achieving higher standards of workmanship.

In a competitive landscape, having the right tools can set businesses apart. By understanding the significant advantages of incorporating a High Speed Air Drill into their toolkit, professionals can elevate their performance and results. With recommendations from industry leaders like John Smith reinforcing the advantages, it is evident that investing in this technology is a strategic move toward achieving excellence in performance.

High-speed air drills are powerful tools designed for various applications, particularly in industries requiring precision and efficiency. These drills operate on the principle of compressed air, which drives the tool's motor at high RPMs (rotations per minute). The mechanism involves an air inlet, which directs compressed air into the motor, causing it to spin rapidly. This high-speed rotation allows for quick drilling, reducing the time needed for tasks significantly compared to traditional electric drills.

Tips for using high-speed air drills effectively include ensuring proper maintenance of the tool. Regularly check for leaks in the air hoses and ensure that the motor components are lubricated to prevent wear and tear. Additionally, it’s essential to choose the right drill bit for the material you are working with to maximize performance and efficiency. Using the appropriate bit helps to reduce friction and improves drilling speed.

Another useful tip is to maintain a steady hand and consistent pressure while drilling. This practice not only enhances the overall finish of the hole but also minimizes the risk of damaging the drill bit or the workpiece. Understanding the mechanics of high-speed air drills can significantly improve your productivity and the quality of your work.

| Feature | Description | Benefits |

|---|---|---|

| High Speed Operation | Operates at high RPMs for faster drilling. | Increases productivity and decreases job completion time. |

| Lightweight Design | Manufactured with lightweight materials for ease of use. | Reduces operator fatigue during extended use. |

| Versatile Applications | Suitability across various materials including metal and plastic. | Enables use in diverse projects and industries. |

| Improved Control | Features ergonomic grips and responsive triggers. | Enhances precision and reduces errors in drilling. |

| Low Noise Operation | Designed to operate quietly compared to electric drills. | Minimizes workplace noise pollution. |

High-speed air drills have emerged as a superior alternative to traditional drills, offering numerous advantages that enhance performance and efficiency. One of the primary benefits of high-speed air drills is their ability to deliver faster rotational speeds compared to electric or manual drills. This increased speed allows for quicker drilling, which can significantly reduce project completion times, especially in high-demand environments. Furthermore, the lightweight design of air drills reduces user fatigue, enabling operators to work longer without discomfort.

In addition to speed and ergonomics, high-speed air drills offer precision that is often unmatched by traditional drills. The consistent torque output provides greater control during operation, allowing users to achieve clean and accurate holes. This level of precision is particularly beneficial in applications where the quality of the workpiece is critical. Additionally, these drills have fewer moving parts, resulting in lower maintenance requirements and enhanced durability over time.

**Tip**: When using a high-speed air drill, always ensure that the air compressor is set to the appropriate pressure level for the job at hand. Too much pressure can lead to overdrilling, while too little can reduce efficiency.

**Tip**: Regularly check and clean the drill's air filter to maintain optimal performance and prevent clogging, which can affect speed and functionality.

The use of high speed air drills significantly enhances work efficiency and productivity across various industries. These tools, designed for rapid and precise drilling, reduce the time required for completing tasks. With their high rotating speeds, they enable workers to drill through various materials swiftly, minimizing downtime and allowing for a quicker turnaround on projects. This efficiency is particularly important in sectors such as construction and manufacturing, where project deadlines are crucial.

Moreover, high speed air drills contribute to improved worker ergonomics and comfort. Traditional drilling methods often lead to fatigue due to the physical exertion required, which can ultimately hamper productivity. In contrast, air drills are lightweight and easy to handle, allowing operators to work for extended periods without excessive strain. This not only enhances individual performance but also promotes a safer working environment, as workers can maintain focus and avoid the risks associated with fatigue. By investing in high speed air drills, businesses can foster a more streamlined workflow, thereby increasing overall productivity and effectiveness in operations.

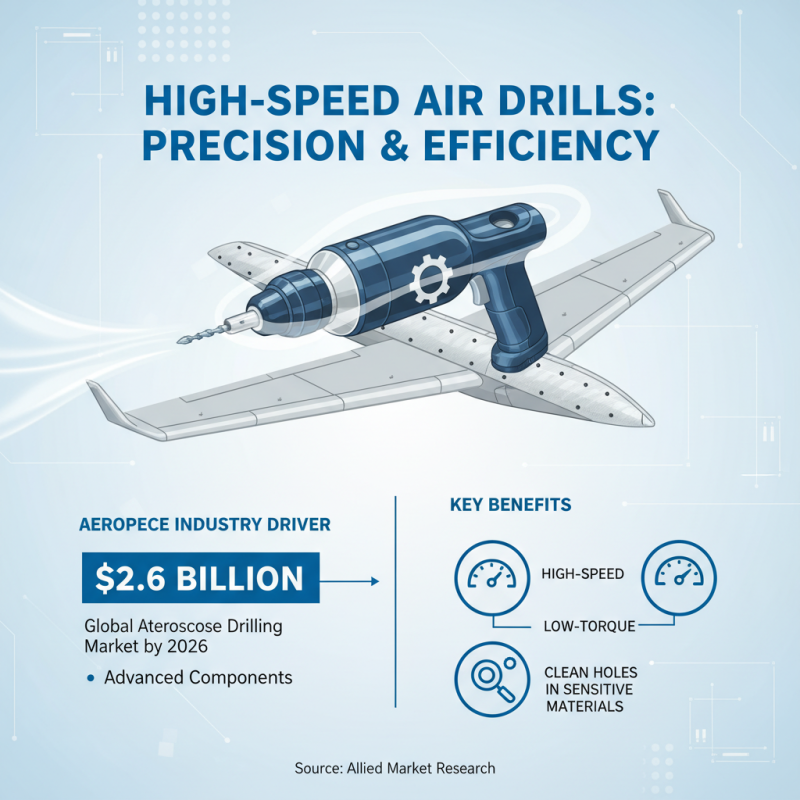

High-speed air drills are integral tools across various industries, enabling enhanced efficiency and precision in operations. In the aerospace sector, for instance, the demand for lightweight materials and intricate designs necessitates the use of high-speed drilling technology. According to a report by Allied Market Research, the global aerospace drilling market is projected to reach $2.6 billion by 2026, driven by the need for advanced components that require precision drilling capabilities. High-speed air drills facilitate this by providing low-torque, high-speed solutions, which are ideal for creating clean holes in sensitive materials without causing damage.

Similarly, in the automotive industry, high-speed air drills are employed for assembling parts with exact tolerances. The market for automotive tools within this context has been projected to expand significantly, with a CAGR of 7.3% from 2021 to 2028. This growth is attributed to innovations in manufacturing processes where high-speed air drills enhance productivity during mass production by minimizing cycle times and ensuring consistency in assembly lines. The ability of these drills to handle various materials like aluminum, steel, and composite components makes them indispensable for manufacturers aiming to optimize operational efficiency.

To maximize the performance of high-speed air drills, proper maintenance is crucial. Regularly inspecting the air valves and filters should be a priority. Clogged filters can reduce airflow and efficiency, leading to suboptimal drilling performance. It's essential to clean or replace these components at regular intervals to ensure smooth operation. Additionally, keeping the drill lubricated according to the manufacturer’s guidelines can prevent wear and tear, thereby extending the lifespan of the tool.

Another important aspect of maintenance is the inspection of the drill bits. Worn or damaged bits can not only cause inefficient drilling but also lead to increased operational challenges. Regularly check for signs of wear, and sharpness should be a priority to maintain drilling effectiveness. When bits become dulled, replacing them promptly will ensure that the drill operates at peak performance. Furthermore, storing the air drill in a dry, protective environment can help avoid rust and damage, promoting longevity and consistent functionality. By following these maintenance tips diligently, users can experience the full benefits of their high-speed air drills in terms of speed and efficiency.