In the world of leather crafting, precision is paramount, and the right tools can significantly impact the quality of the final product. The "Leather Strap Cutting Machine" stands out as an essential piece of equipment for artisans dedicated to achieving excellence in their craft. According to leatherwork expert Johnathan Reid, "A well-calibrated cutting machine transforms raw leather into a canvas of possibilities, allowing makers to focus on creativity rather than manual errors." This statement highlights the critical role that precise cutting plays in the overall craftsmanship of leather goods.

As we delve into the intricacies of mastering leather strap cutting, we will explore the essential features, benefits, and types of Leather Strap Cutting Machines available on the market. From manual to automated options, understanding these machines can help craftsmen select the best equipment that aligns with their specific needs. Emphasizing the significance of precision, our guide aims not only to inform but also to inspire artisans to elevate their leather crafting skills through the right tools.

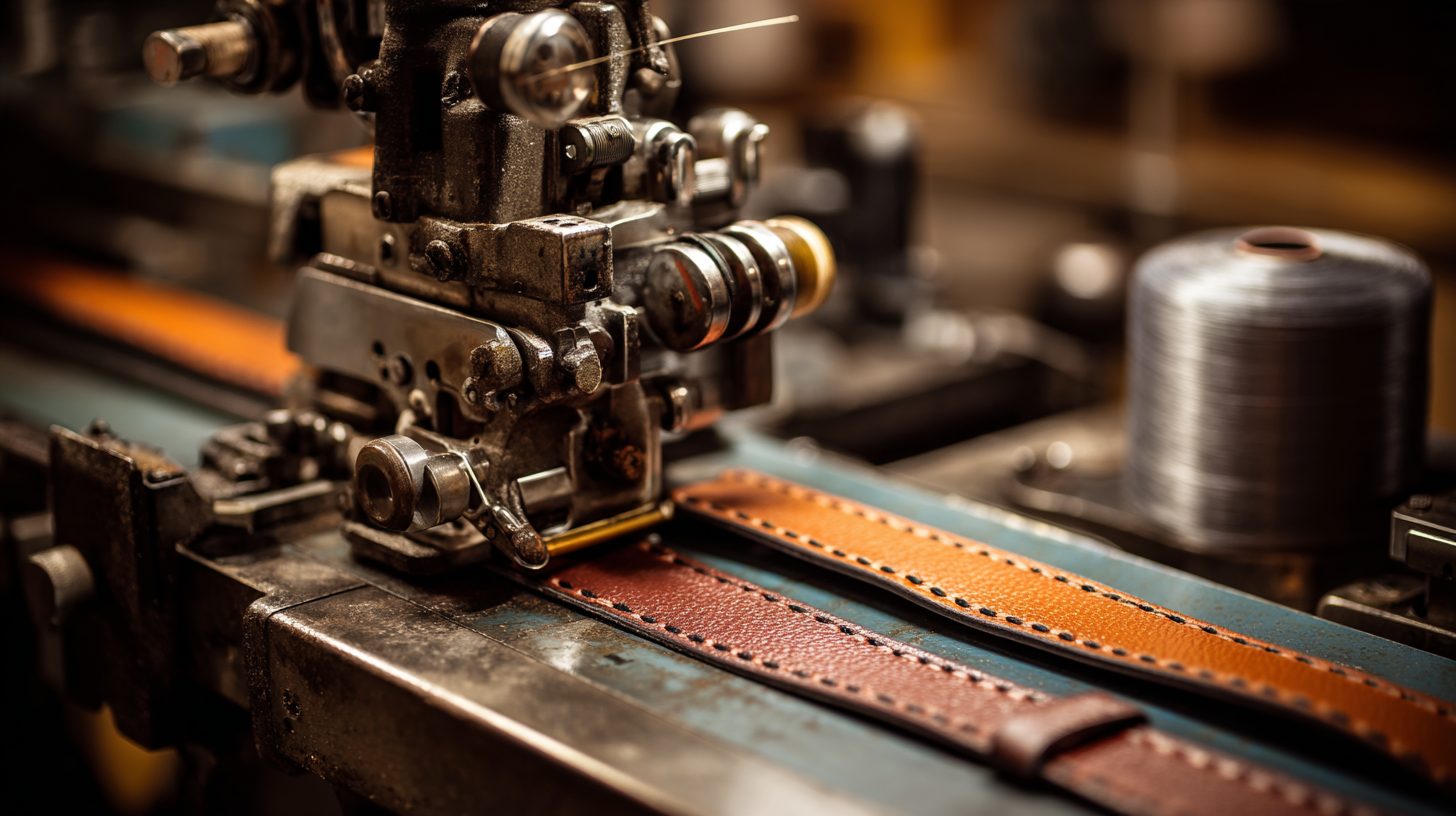

When it comes to crafting high-quality leather goods, precision is paramount. Leather strap cutting machines are designed to ensure exact cuts, streamlining the crafting process and enhancing the overall product quality. Key features to consider include adjustable cutting depths, blade sharpness, and the ability to handle various leather thicknesses. Selecting a machine with a robust construction will also ensure durability and consistent performance over time.

Tips for choosing a leather strap cutting machine include assessing your specific needs, such as the volume of production and the complexity of designs you aim to achieve. Make sure to test the machine for ease of use and adjustability, as these factors can significantly affect your workflow. Additionally, look for machines that offer safety features, ensuring a secure working environment while maintaining high efficiency.

Another important aspect is maintenance. Regular blade sharpening and machine cleaning can prolong the life of your equipment and maintain cutting precision. Invest in high-quality blades and familiarize yourself with the manufacturer's guidelines to optimize performance and ensure your creative projects come to life with finesse.

| Feature | Description | Importance |

|---|---|---|

| Cutting Precision | Ability to cut leather straps accurately to specified dimensions. | Ensures high-quality finished products with minimal waste. |

| Blade Type | Variety of blades available, including rotary and straight blades. | Different blades cater to various types of leather and cutting styles. |

| Speed Settings | Adjustable speed settings for different cutting tasks. | Enhances precision and control during the cutting process. |

| Material Compatibility | Capable of cutting various materials besides leather, such as fabric and rubber. | Flexibility for multi-material crafting projects. |

| Safety Features | Includes guards, automatic shut-off, and safety locks. | Protects users from accidents during operation. |

| Portability | Compact and lightweight design for easy transport. | Ideal for workshops and crafting events on the go. |

| User Interface | Intuitive controls with digital displays for ease of use. | Reduces learning curve and enhances operational efficiency. |

Automated leather cutting solutions have revolutionized the crafting industry, offering a range of benefits that elevate quality and efficiency. One of the key advantages is precision; CNC machines ensure that cuts are made to exact specifications, reducing material waste and enhancing the overall quality of the final product. According to industry reports, the CNC machine blade market is projected to expand significantly, with significant growth attributed to the increasing demand for accuracy in manufacturing processes. The adoption of high-speed steel and carbide blades is on the rise, offering crafters enhanced performance when working with various materials, including leather.

Automated leather cutting solutions have revolutionized the crafting industry, offering a range of benefits that elevate quality and efficiency. One of the key advantages is precision; CNC machines ensure that cuts are made to exact specifications, reducing material waste and enhancing the overall quality of the final product. According to industry reports, the CNC machine blade market is projected to expand significantly, with significant growth attributed to the increasing demand for accuracy in manufacturing processes. The adoption of high-speed steel and carbide blades is on the rise, offering crafters enhanced performance when working with various materials, including leather.

Moreover, automated leather cutting machines significantly reduce production time, allowing artisans to focus on creativity rather than labor-intensive cutting processes. As reported, the shift towards automation in industries like automotive and aerospace has further popularized these technologies, underscoring the importance of efficiency. With advancements in blade geometry, including single-point and multi-point designs, users benefit from optimized cutting performance tailored to specific applications. The integration of such technology not only increases output but also improves consistency across products, making automated solutions indispensable for modern craftsmanship.

Achieving accuracy in leather cutting is crucial for professionals and hobbyists alike, as it directly impacts the quality of the final product. The first step in mastering precision is selecting the right tools. High-quality cutting machines equipped with sharp blades can make a significant difference in ensuring clean cuts. Additionally, consider using cutting mats specifically designed for leather, as they provide a stable surface and prevent blade wear. A reliable ruler or cutting guide can further enhance your ability to achieve straight lines and consistent widths in your leather straps.

Techniques also play a vital role in achieving precision. Familiarize yourself with different cutting methods, such as die cutting or rotary cutting, to find what works best for your projects. Practicing on scrap pieces of leather can help refine your skills and build confidence before working on your final materials. Moreover, maintaining a steady hand and proper body posture during the cutting process can reduce the likelihood of errors. By combining the right tools with effective techniques, you can elevate your leather crafting projects to new heights of excellence.

When selecting a leather strap cutting machine, understanding machine specifications is crucial for achieving the desired thickness and versatility. Different machines are designed to accommodate various leather types, from soft suede to thick full-grain leather. It's essential to check the blade type and cutting action, as these components significantly affect how smoothly the machine can handle different leather thicknesses. A machine with adjustable pressure settings can enhance your ability to work with a wide range of materials.

**Tips:** Always test your machine with scrap pieces of leather to determine the optimal settings for thickness and type. This practice will prevent costly mistakes and ensure that you can fine-tune your machine for specific leather attributes.

Moreover, consider the adaptability of the machine. Many modern strap cutting machines offer additional attachments or features that enable users to switch between cutting styles or shapes easily. This versatility can be particularly beneficial for crafters who work with various leather products. Investing in a machine that can handle multiple leather types not only broadens your crafting capabilities but also elevates the overall quality of your work.

**Tips:** Research customer reviews and feedback on various models to find one that meets your specific needs for versatility and precision in leather crafting.

This chart compares the maximum leather thickness capabilities and the versatility in types of leather supported by various leather strap cutting machines. Understanding these specifications is essential for craftsmen aiming for excellence in leatherworking.

The leather crafting industry has witnessed a significant transformation with the rising adoption of precision cutting machines. As artisans strive for higher quality and efficiency, these machines have become indispensable tools. Market trends indicate that more leather craftsmen are transitioning from traditional cutting methods to automated solutions, allowing for intricate designs and consistent results. This shift not only enhances the quality of leather products but also boosts productivity, enabling businesses to meet growing demand.

Moreover, the increasing availability of advanced software and technology has further propelled the integration of precision cutting machines in leather crafting. These innovations allow users to customize patterns and optimize material usage, minimizing waste. As the market continues to evolve, it is clear that precision cutting machines are not just a luxury but a necessity for maintaining competitive advantage in the leather industry. This growing trend reflects a broader movement towards tech-driven craftsmanship, where skill meets innovation to create unparalleled craftsmanship.