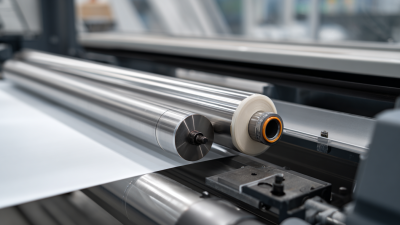

As the 138th China Import and Export Fair approaches in 2025, the Conveyor Belt Slitting Machine industry is expected to experience significant transformations driven by advances in technology and shifts in market demand. According to a recent report by Market Research Future, the global conveyor belt slicing market is projected to grow at a CAGR of 5.2% between 2021 and 2027, largely fueled by expansions in manufacturing and logistics sectors. In particular, automation and precision in slitting operations are becoming increasingly vital as companies prioritize efficiency and cost-effectiveness. This shift not only enhances productivity but also aligns with the broader Industry 4.0 trend, where smart manufacturing and interconnected systems define operational excellence. The upcoming fair will highlight these emerging trends and showcase innovations that cater to an evolving landscape, making it a pivotal event for stakeholders within the Conveyor Belt Slitting Machine sector.

The conveyor belt slitting machine industry is poised for significant advancements as we approach the 2025 China Import and Export Fair. Emerging technologies in this sector are crucial for optimizing production efficiency and meeting global market demands. According to a report, the global conveyor segment is expected to reach a staggering US$9.2 billion by 2030, driven by a compound annual growth rate (CAGR) of 5.7%. Innovations specifically tailored for conveyor belt slitting machines emphasize improved precision and speed, helping manufacturers enhance operational capabilities and reduce waste.

Furthermore, industries are increasingly integrating advanced machine learning and computer vision technologies into their manufacturing processes. These developments not only streamline sorting and processing in applications like agriculture but also raise the bar for quality control in conveyor operations. The advancements in smart technologies are crucial for adapting to the ever-evolving requirements of operators and consumers alike, positioning the conveyor belt slitting machine industry to thrive in a competitive global market. As we advance towards 2025, the synergy of innovation and market adaptability will be essential for manufacturers seeking to leverage these emerging trends.

| Trend | Description | Projected Impact | Market Demand |

|---|---|---|---|

| Automation Integration | Increased use of automated systems for slitting processes, improving efficiency. | High | Rising due to labor cost reductions and higher throughput needs. |

| Eco-friendly Materials | Shift towards using recyclable and sustainable materials in production. | Medium | Increasing as regulatory pressures rise and consumer preferences shift. |

| Data Analytics | Utilization of data analytics for optimizing production and maintenance. | High | Growing demand for better operational insights and efficiency. |

| Customizable Solutions | Increase in demand for flexible, customizable machine configurations. | Medium | Rising as different industries seek specialized solutions. |

| Smart Technologies | Integration of IoT and AI technologies for smarter operations. | High | Strong growth anticipated with the rise of Industry 4.0. |

The 2025 China Import and Export Fair is set to spotlight the conveyor belt slitting machine industry, particularly highlighting the innovations brought forth by key players in the sector. Companies like Yancheng City Dongfang Machinery Co., Ltd. and Hangzhou Hanghu Machine Co., Ltd. are leading the way with advancements that focus on efficiency and automation. Recent industry reports indicate that the global market for conveyor belt slitting machines is expected to grow by approximately 7.2% CAGR from 2023 to 2028, reflecting a rising demand for high-precision cutting technologies and customization in manufacturing processes.

Innovations in this field include the integration of AI-driven control systems that enhance operational precision and reduce waste. For instance, Xuzhou Xinyao Machinery Co. has developed a new line of slitting machines that utilize advanced sensors and analytics, which reportedly improve cutting accuracy by up to 30%. Additionally, sustainable practices are becoming increasingly crucial as companies strive to reduce their environmental footprint. Reports suggest that over 60% of manufacturers are investing in eco-friendly materials and energy-efficient machinery, aligning with global sustainability goals while meeting the diverse needs of the conveyor belt market.

The impact of trade policies on the conveyor belt machinery sector has become increasingly significant, especially in light of the recent tariffs imposed by the U.S. government. The 25% tariffs on imports from Canada and Mexico are expected to create ripples across various industries, including machinery manufacturing. According to a recent industry report, the conveyor belt slitting machine market is projected to grow at a CAGR of 6.7% from 2023 to 2028, reaching an estimated value of $2 billion by 2025. With the complexities of international trade agreements playing a major role, manufacturers must navigate these challenges carefully to maintain their competitive edge.

Moreover, the evolving landscape necessitates a proactive approach to supply chain management. Exporters and importers are urged to stay informed about the changing trade dynamics and adjust their strategies accordingly. For instance, companies can consider diversifying their suppliers to mitigate risks associated with tariffs. As the fair approaches, it will be crucial for industry players to showcase innovations in conveyor belt slitting machines while addressing how their businesses adapt to trade policy changes.

Tip: Engage with industry experts during the fair to gain insights on how to leverage the evolving trade policies for business growth.

In addition, embracing automation and advanced technology in production lines can help offset increased costs from tariffs. By investing in smarter machinery, companies can improve efficiency and reduce operational overhead, thus maintaining profitability in a tightening market.

The conveyor belt slitting machine industry is currently experiencing significant transformations driven by evolving market trends and customer demands. As industries seek enhanced efficiency and automation, the demand for advanced slitting machines is on the rise. Customers are increasingly looking for machines that not only improve precision and speed but also integrate smart technologies such as IoT capabilities for better monitoring and control of production processes. This shift towards automation indicates a clear preference for machines that can deliver higher output while reducing operational costs.

Moreover, sustainability is becoming a crucial factor in the decision-making process for purchasing slitting machines. Customers are more inclined to favor equipment that minimizes waste and promotes environmentally friendly practices in manufacturing. This trend is influencing manufacturers to innovate and offer machines that utilize energy-efficient technologies and recyclable materials. As the industry progresses towards 2025, these emerging trends will play a pivotal role in shaping product offerings and competitiveness in the conveyor belt slitting machine market.

As the global industry shifts toward sustainable practices, the conveyor belt slitting machine manufacturing sector is increasingly embracing eco-friendly methods. Manufacturers are now utilizing biodegradable materials and energy-efficient technologies to minimize their environmental footprint. These innovations not only comply with regulatory standards but also attract environmentally conscious clients who prioritize sustainability in their purchasing decisions.

Tips: When selecting a supplier for conveyor belt slitting machines, check their commitment to sustainable practices. Look for certifications like ISO 14001, which indicates strong environmental management systems.

Incorporating recycled materials into production processes is another emerging trend in the industry. This reduces waste and lowers costs, reflecting a double win for manufacturers. As more companies adopt these practices, the competition will intensify, pushing others to follow suit and innovate further. By investing in sustainable technologies, firms can enhance their brand reputation and appeal to a broader audience.

Tips: Evaluate the sustainability of machinery by asking potential suppliers about their recycling policies and waste management strategies. Engaging with vendors who share these values can significantly improve your sourcing practices.