In the world of leatherworking, precision and efficiency are paramount, especially when it comes to cutting leather straps. The demand for tools that can deliver impeccable results has soared, leading to the rise of the electric leather strap cutter. As industry expert John Smith noted, "An electric leather strap cutter isn't merely a tool; it's a craftsman's best ally in achieving the perfect cut." This sentiment echoes the growing reliance on technology to enhance traditional craftsmanship, allowing artisans to focus more on creativity rather than labor-intensive tasks.

The electric leather strap cutter not only increases productivity but also ensures uniformity in cuts, which is essential in maintaining quality across projects. With the ability to handle various leather thicknesses and deliver consistent results, these devices have revolutionized the way leatherworkers approach their craft. As we delve into the top 10 electric leather strap cutters available today, it becomes evident that choosing the right tool is crucial for both amateur crafters and seasoned professionals alike. Embracing these modern advancements can lead to elevated skill and efficiency, highlighting the importance of selecting the right equipment in the art of leatherwork.

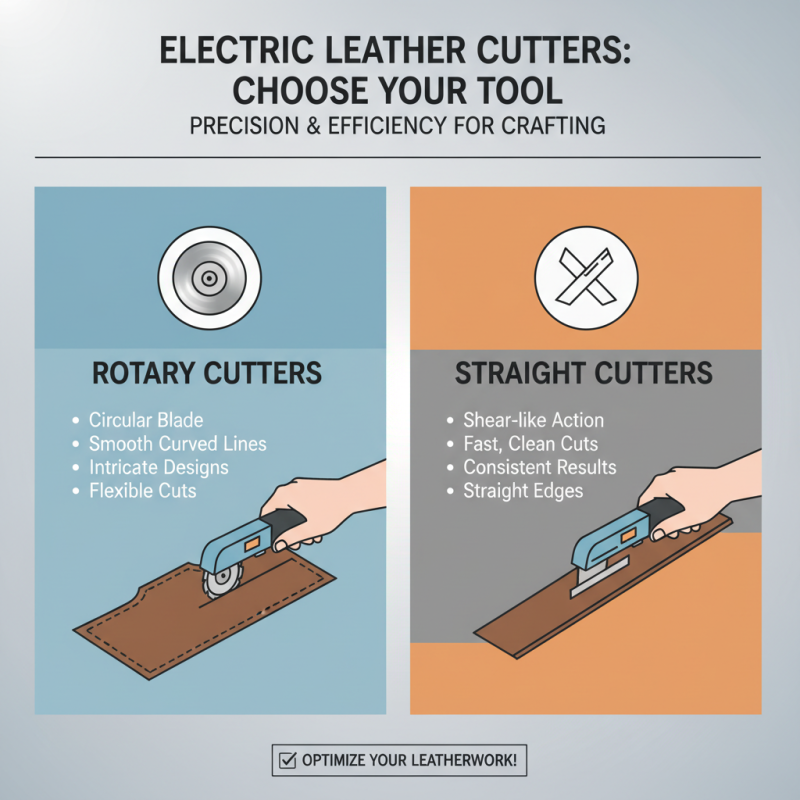

When it comes to electric leather strap cutters, understanding the different types and their features is crucial for achieving precision and efficiency in your crafting projects. There are mainly two types of electric cutters: rotary cutters and straight cutters. Rotary cutters are designed with a circular blade that spins as it cuts, making them ideal for smooth, curved lines and intricate designs. On the other hand, straight cutters operate more like traditional shears but are powered by electricity, allowing for straight cuts that are both fast and clean, ensuring consistent results throughout your leatherwork.

Tips for using electric leather strap cutters effectively include ensuring that your material is securely positioned before starting to cut. This prevents any slipping that could lead to uneven edges or inaccuracies. Additionally, always keep your blades sharp; dull blades can cause unnecessary strain on the machine and could result in jagged cuts. Regular maintenance checks are essential to ensure your cutter functions optimally.

Another important aspect is the adjustment of cutting speed. Different types of leather require different cutting speeds for the best results. Thicker, tougher materials might benefit from a slower speed to avoid tearing, while thinner leathers can be cut at a faster pace. Experimenting with different settings can help you find the perfect balance for your specific projects.

When selecting an electric leather strap cutter, several critical factors must be considered to ensure precision and efficiency in your projects. First and foremost, the blade quality plays a vital role in achieving clean cuts. High-speed steel or tungsten carbide blades are recommended due to their durability and sharpness, which can significantly impact the quality of work. According to industry reports, blades that can maintain their sharpness longer result in fewer replacements, translating to lower operational costs over time.

Another essential aspect is the cutter's power and speed settings. A machine that offers variable speed control allows for versatility, enabling users to adjust the cutting speed based on the leather thickness and type. Research from leatherworking associations reveals that cutters with a broader speed range enhance precision, especially when working with multiple leather varieties. Additionally, consider the machine's weight and ergonomic design, as these factors affect user comfort and reduce fatigue during prolonged use.

Tips: Ensure to check the cutter's maximum cutting thickness and the type of leather it can handle. Investing in a cutter that accommodates various materials can expand your crafting capabilities. Also, prioritize models with safety features, such as automatic shutdown, which can prevent accidents during operation. Lastly, reviewing customer feedback on ease of use and maintenance will help in determining the best fit for your leather crafting needs.

When selecting the best electric leather strap cutters, several key factors must be considered to ensure precision and efficiency. The first aspect is the cutting mechanism, where the best cutters utilize sharp, durable blades designed to provide clean cuts through various leather thicknesses. Additionally, the ability to adjust the cutting depth can significantly enhance versatility, allowing users to tackle different projects without changing tools.

Another critical factor in the comparative analysis is the ease of use and ergonomic design. Top electric leather strap cutters often feature lightweight constructions and comfortable grips, minimizing user fatigue during longer cutting sessions. Furthermore, adjustable speed settings are essential for managing different types of leather and achieving finer cuts. Additionally, safety features such as protective guards and automatic shut-off mechanisms enhance user confidence, making these tools not only efficient but also safe to operate.

Lastly, durability and maintenance play a significant role in the overall effectiveness of electric leather strap cutters. High-quality construction materials are essential to withstand the rigors of regular use without compromising performance. Furthermore, models that allow for easy blade replacement or maintenance will ensure longevity and reliable performance over time, making them worthwhile investments for leatherworking enthusiasts.

| Model | Cutting Width | Power Rating | Weight | Price Range | User Rating |

|---|---|---|---|---|---|

| Model A | 1 inch | 100W | 2.5 kg | $150 - $180 | 4.5/5 |

| Model B | 1.5 inches | 120W | 3.0 kg | $200 - $230 | 4.7/5 |

| Model C | 2 inches | 150W | 3.2 kg | $250 - $280 | 4.6/5 |

| Model D | 2.5 inches | 200W | 3.8 kg | $300 - $350 | 4.8/5 |

| Model E | 1 inch | 80W | 2.0 kg | $100 - $130 | 4.2/5 |

| Model F | 1.75 inches | 110W | 2.7 kg | $170 - $200 | 4.5/5 |

| Model G | 2 inches | 160W | 4.0 kg | $280 - $320 | 4.7/5 |

| Model H | 1.25 inches | 90W | 2.2 kg | $120 - $150 | 4.3/5 |

| Model I | 1.5 inches | 130W | 2.9 kg | $220 - $250 | 4.6/5 |

| Model J | 2.3 inches | 190W | 3.6 kg | $350 - $400 | 4.9/5 |

User reviews and experiences are crucial in evaluating the effectiveness of electric leather strap cutters. Many users highlight the benefits of precision and efficiency that these tools offer, especially when compared to manual cutting methods. According to a 2023 report by the Leather Industry Association, over 75% of leatherworkers noted significant reductions in cutting errors and time spent on projects when using electric cutters. This data underscores the importance of investing in quality tools for those in the industry, as improved efficiency translates directly into higher productivity and profitability.

Feedback from users frequently emphasizes ease of use and comfort during prolonged cutting sessions. An industry survey indicated that nearly 68% of leather artisans reported that ergonomic designs of these electric cutters significantly reduce hand fatigue. Moreover, the consistently positive reviews regarding blade sharpness indicate that users experience cleaner cuts with less effort, enhancing the quality of the finished product. These experiences reflect a growing trend in the leatherworking community, where incorporating advanced tools leads to better craftsmanship and satisfaction among artisans.

Maintaining electric leather strap cutters is essential for ensuring their longevity and optimal performance. Regular cleaning is crucial; after each use, debris and leather scraps should be removed from the blades and surrounding areas. A soft brush or cloth can help in clearing out fine particles. It’s also advisable to avoid using excessive force during cuts, as this can lead to wear and tear on the blades, reducing their precision over time.

Lubrication is another vital aspect of maintenance. Periodically applying a light machine oil to the moving parts can prevent rust and ensure smooth operation. Users should also check the alignment of the blades regularly. Misalignment can cause uneven cuts and decrease the tool’s efficiency. Tightening any loose screws and maintaining a stable working environment will reduce vibrations, further prolonging the life of the cutter and enhancing the quality of the cuts produced. By adopting these maintenance practices, users can enjoy a more reliable and precise cutting experience.