In the manufacturing and logistics sectors, efficiency is crucial. Conveyor systems play a vital role in streamlining operations. A key component of these systems is the Conveyor Belt Slitter. This tool facilitates the precise cutting of conveyor belts. It helps in customizing belt sizes to fit various machinery.

Recent industry reports indicate that the conveyor belt manufacturing market is projected to reach $6.15 billion by 2025. The demand for tailored solutions drives the need for effective slitting tools. However, precision in cutting is not always achieved. Operators must ensure they employ proper techniques and maintenance. Misalignment in slitting could lead to increased waste and higher costs.

The Conveyor Belt Slitter is essential, yet challenges persist. Operators should receive adequate training to optimize performance. They must regularly assess the equipment to avoid unnecessary downtime. In a fast-paced environment, overlooking these factors can hinder production efficiency. The balance between quality and speed remains a continuous quest.

A conveyor belt slitter serves a critical role in manufacturing and material handling. It is designed to cut wide conveyor belts into narrower strips. This helps optimize the use of materials and improves efficiency in production processes. According to a market report, the demand for conveyor belt slitters is expected to grow by 5% annually over the next five years.

The primary purpose of a conveyor belt slitter is to enhance the adaptability of conveyor systems. Industries like mining, packaging, and food processing benefit significantly from this technology. Slitting allows for customization based on specific project requirements. Different widths can be produced to cater to distinct operational needs. Companies can utilize leftover belt material more efficiently through this process, reducing waste.

However, there are challenges associated with using conveyor belt slitters. Operators must constantly monitor the cutting process to ensure precision. Inadequate maintenance can lead to uneven cuts, compromising the product's integrity. According to some industry studies, improper usage can reduce the lifespan of both the slitter and the conveyor system. Regular training and operational reviews are essential for maintaining performance levels. It’s worth noting that some manufacturers still overlook these key aspects.

Conveyor belt slitters are essential tools in many industries. They customize conveyor belts to meet specific needs. Various types of slitting machines exist, each serving different applications.

Rotary slitters are common in the manufacturing sector. They use circular blades to cut belts into precise widths. This method ensures minimal waste, maximizing material use. Another type is the guillotine slitter. It operates with a straight blade, suitable for thicker materials. This approach can be less precise, but it is still effective for general trimming.

Many industries benefit from these machines. Packaging companies often require specific belt sizes for their operations. Food production facilities might need sanitizable belts cut to fit their machines. Each application comes with unique requirements. Reflection on the process reveals opportunities for improvement. Users must continually assess how to enhance efficiency and quality.

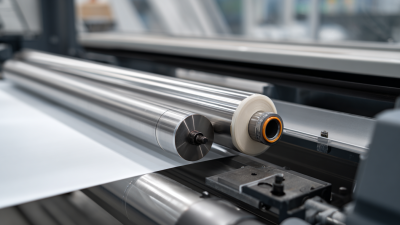

A conveyor belt slitter is a crucial tool in various industries. It slices conveyor belts into specified widths. Understanding how slitting machines operate is essential for effective use. These machines rely on sharp blades and precise controls.

Mechanically, conveyor belt slitters use rotating blades. The blades move quickly, cutting through tough materials. Tension is important; belts must be taut for clean cuts. Operators adjust the machine settings carefully. Improper settings may result in uneven slices or damaged belts. Inaccuracies can lead to wastage or costly repairs.

Tips: Regular maintenance can prolong the life of a slitting machine. Inspect blades for wear and replace them when necessary. Proper alignment is key. Misalignments can cause additional strain. Monitor the machine during operation, looking for unusual noises or vibrations. Addressing issues early can prevent bigger problems later.

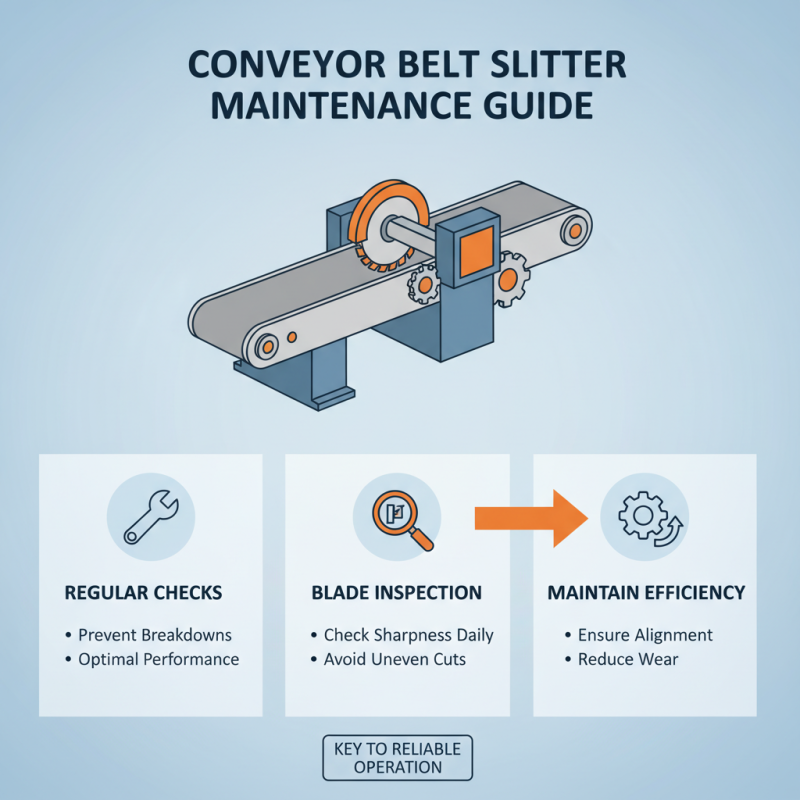

Maintaining a conveyor belt slitter is essential for optimal performance. Regular checks can prevent breakdowns. It's vital to inspect the blade condition frequently. Dull blades can lead to uneven cuts and excess wear on the machine. Ensure that the blade is sharp and properly aligned to maintain cutting efficiency.

Cleaning the slitter is another key task. Dust and debris can accumulate quickly. A clean machine operates smoothly. Use compressed air or a soft brush for safe cleaning. Regular lubrication of moving parts also helps to reduce friction. Remember, neglect can lead to costly repairs and downtime.

Check the tension of the conveyor belts routinely. Loose belts can cause slippage. This may affect the cutting precision. Adjust the tracking as needed to ensure that the slitter runs straight. Sometimes, operators overlook these details. A small adjustment can greatly enhance performance.

Safety is vital when using a conveyor belt slitter. These machines, while efficient, can pose risks if proper precautions are not taken. According to industry data, around 33% of workplace injuries arise from machinery-related incidents. Understanding operational safety can significantly reduce these risks.

Operators should wear appropriate personal protective equipment (PPE). This includes safety goggles, gloves, and steel-toed boots. Inadequate PPE is a common oversight. It's essential to ensure that all equipment is well-maintained and regularly inspected. These checks can prevent mechanical failures that might lead to accidents.

Another key consideration is ensuring a clear working area. Clutter can lead to accidents, and many workers underestimate this risk. Training staff on emergency procedures is equally crucial. About 40% of workers feel unprepared for emergencies. Regular drills help reinforce safety measures and build confidence among the workforce. Implementing these safety practices will enhance awareness and can lead to a culture of safety in the workplace.

| Dimension | Description | Safety Consideration |

|---|---|---|

| Working Width | The maximum width of the belt that can be slit | Ensure adequate space around the machine for operation |

| Cutting Speed | Speed at which the blade moves to cut the belt | Use proper protective gear to avoid injury from fast-moving parts |

| Blade Type | Type of blade used for slitting | Regularly check blade sharpness to reduce risks |

| Power Source | Source of energy used to operate the slitter | Ensure proper wiring and maintenance to prevent electrical hazards |

| Operator Training | Training provided to personnel for safe operation | Implement ongoing training and refreshers for safety compliance |