In the rapidly evolving leather industry, the demand for precision and efficiency has never been greater, making the choice of the right machinery pivotal for business success. According to a report by Smithers Pira, the global leather goods market is expected to reach a staggering $413 billion by 2025, highlighting the need for businesses to invest in high-quality tools to maintain a competitive edge.

One critical piece of equipment is the Leather Strap Cutting Machine, which not only enhances productivity but also ensures consistent quality in strap production. With various models and features available, selecting the right machine tailored to specific business needs can significantly impact operational efficiency. In this ultimate guide, we will explore key considerations and factors to help you choose the most suitable Leather Strap Cutting Machine for your business.

One critical piece of equipment is the Leather Strap Cutting Machine, which not only enhances productivity but also ensures consistent quality in strap production. With various models and features available, selecting the right machine tailored to specific business needs can significantly impact operational efficiency. In this ultimate guide, we will explore key considerations and factors to help you choose the most suitable Leather Strap Cutting Machine for your business.

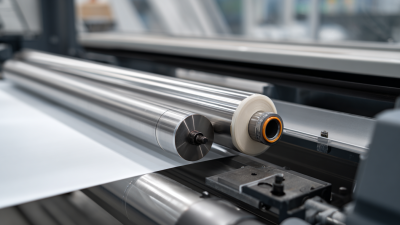

When selecting the right leather strap cutting machine for your business, there are several key features and specifications that should guide your decision-making process. First and foremost, consider the machine's cutting capacity. This includes both the thickness of leather it can handle and the maximum width of the straps. Machines designed for thicker materials often come with more robust cutting components, ensuring precise and clean cuts essential for high-quality leather products.

Another important consideration is the type of cutting mechanism used. Options range from manual to automated systems, with some advanced machines featuring digital controls that enhance accuracy and reduce material waste. Additionally, consider the speed and efficiency of the machine, especially if your business demands high production rates. Look for machines that offer adjustable speeds to accommodate various project requirements while maintaining optimal performance. Finally, don't overlook the importance of build quality and warranty options, as these factors can significantly impact your long-term satisfaction and machine reliability in a demanding business environment.

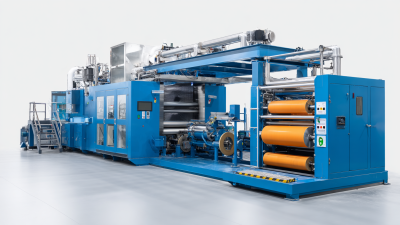

When selecting a leather strap cutting machine, understanding the various types available is crucial for optimizing your business operations. There are primarily two categories of machines: manual and automatic.

Manual machines typically cater to smaller businesses or hobbyists, offering a cost-effective solution that allows for precise cuts without the need for extensive machinery. However, they require a more hands-on approach, which can slow down production rates.

On the other hand, automatic leather strap cutting machines are designed for larger scale operations, providing speed and efficiency. These machines often feature advanced technology, such as programmable cutting patterns, which enable businesses to produce consistent and intricate designs with minimal labor.

Applications for these machines extend beyond just leatherworking; they can be leveraged in various industries, including fashion, accessories, and upholstery. Understanding these distinctions will help you choose a machine that not only meets your immediate needs but also supports your business growth in the long run.

When choosing a leather strap cutting machine, the cost-effectiveness of your investment plays a vital role in ensuring long-term business success. It's essential to balance quality with budget while exploring various options in the market.

High-quality machines may come at a premium, but their durability and performance can lead to significant savings over time. By carefully assessing the specifications and capabilities of each machine, you can avoid potential pitfalls that arise from cheaper, less reliable alternatives.

Moreover, it's crucial to consider the specific needs of your business. Different machines cater to varying production scales and complexities, so identifying your primary requirements will streamline the decision-making process.

Invest time in comparing not just initial costs but also factors such as maintenance expenses, replacement parts availability, and the manufacturer’s warranty. This comprehensive evaluation will empower you to make informed choices that align with your financial constraints while ensuring that you invest in a machine that meets your quality standards.

When choosing a leather strap cutting machine, the performance and reliability of the equipment are paramount factors to consider. Leading industry brands such as Tandy Leather, Cobra, and Pro-Series have set high standards in crafting machines that not only meet but exceed the expectations of leather artisans. Tandy Leather, for instance, is renowned for its user-friendly design and precision, making it ideal for both beginners and seasoned professionals. Their machines often come equipped with adjustable settings that allow for intricate cuts, ensuring that each strap is made with absolute accuracy.

In comparison, Cobra's range of cutting machines is celebrated for its heavy-duty construction and robust capabilities. These machines are designed to handle thicker leather, making them suitable for businesses focused on high-volume production. The durability of Cobra models translates to a reliable investment, minimizing downtime and maintenance costs. Furthermore, Pro-Series machines offer innovative features like automatic feed systems, which enhance efficiency and reduce labor efforts. By evaluating the strengths of these top brands, businesses can select a leather strap cutting machine that aligns perfectly with their operational needs and production goals.

When it comes to maintaining your leather strap cutting machine, implementing best practices can significantly enhance its longevity and efficiency. Regular maintenance not only ensures optimal performance but also minimizes operational costs. According to industry reports, machines that are well-maintained can last up to 30% longer than those that are neglected. This involves routine cleaning, lubrication, and calibration, which can reduce wear and tear over time.

One critical aspect of maintenance is the inspection of cutting blades. Sharp, well-aligned blades are essential for precision cuts and can impact the overall quality of the products. A study from the Leather Innovation Institute highlights that proper blade maintenance can improve cutting accuracy by over 20%. Additionally, keeping the machine environment clean and free of debris can prevent unnecessary breakdowns and prolong its lifespan.

Lastly, staying informed about your machine’s specific requirements is crucial. The manufacturer's guidelines often contain vital information about maintenance schedules and recommended practices. Investing in training for your staff on machine upkeep may yield significant returns, as a knowledgeable workforce can spot potential issues before they escalate into costly repairs. Following these best practices will ensure that your leather strap cutting machine remains an asset for years to come.