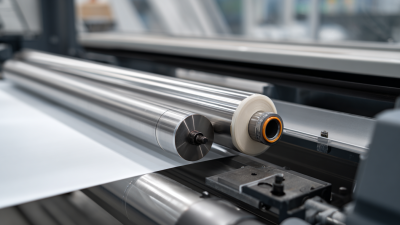

In the dynamic world of manufacturing, selecting the right equipment is crucial for optimizing production efficiency and maintaining product quality. Among the various machines that play a vital role in the production process, the Rubber Belt Layering Machine stands out for its ability to streamline operations and enhance product durability. Whether you are in the automotive industry, textiles, or any sector that utilizes rubber components, understanding how to choose the best Rubber Belt Layering Machine tailored to your specific business needs is paramount. This decision not only impacts your workflow but also affects the overall reliability of your products. In this blog, we will explore key factors to consider when selecting a Rubber Belt Layering Machine, including features, compatibility with existing processes, and potential return on investment, ensuring you make an informed choice that drives your business forward.

When it comes to selecting the right rubber belt layering machine for your business, understanding the various types available is crucial. Rubber belt layering machines are designed for different applications, each requiring specific features to optimize performance. For instance, continuous layering machines are perfect for high-volume production as they provide rapid and consistent layering, making them suitable for manufacturing conveyor belts and automotive components. On the other hand, semi-automatic and manual machines are ideal for smaller operations that may require flexibility and customization in their layering processes.

Another important factor to consider is the type of rubber used in your applications. Machines specialized for handling various rubber compounds can enhance the quality and durability of the end product. Some machines are crafted to work with specialty rubbers like silicone or neoprene, while others may be versatile enough to handle a range of materials. Evaluating your specific needs, such as production speed and material compatibility, will guide you in choosing the machine that will best serve your business requirements.

This chart compares the efficiency of various types of rubber belt layering machines in terms of units produced per hour. Understanding these metrics can help your business select the best machine suited to your production needs.

When selecting an alternative layering machine for your business, several key features should be at the forefront of your decision-making process. First, consider the machine’s compatibility with various rubber belt types. The ability to adjust and accommodate different thicknesses and materials can significantly enhance your production versatility and efficiency. You should look for machines that offer quick-change capabilities, allowing for fast transitions between jobs without extensive downtime.

Next, evaluate the automation level of the layering machine. Advanced automation features can streamline your processes, reduce labor costs, and minimize human error. Machines equipped with smart sensors and programmable controls can provide real-time monitoring and adjustments, ensuring consistent quality across production runs. Additionally, check the machine's ease of maintenance and availability of support from the manufacturer. A user-friendly design will save time and resources during operation, while responsive customer service can be invaluable for troubleshooting and spare parts supply.

| Feature | Importance | Recommended Specification | Benefits |

|---|---|---|---|

| Layering Width | High | At least 300mm | Suitable for a variety of sizes |

| Layering Speed | Medium | 20-40 m/min | Increases productivity |

| Control System | High | Digital with touchscreen | User-friendly operation |

| Build Material | Medium | Stainless Steel | Durable and easy to clean |

| Power Supply | High | 220V / 380V | Suitable for heavy-duty use |

When it comes to choosing the best rubber belt layering machine for your business, understanding the cost-effectiveness of various models is crucial. According to a report from the Rubber Manufacturing Association, the initial investment for a high-capacity rubber belt layering machine can range from $15,000 to $50,000, depending on features and automation levels. However, the return on investment (ROI) can be substantial, with studies indicating that businesses often see a 20-30% increase in production efficiency within the first year of operation.

Tips: Evaluate the long-term operational costs, including maintenance and energy consumption, which can significantly affect your overall expenditures. A machine that is initially more expensive might save you money in the long run if it has a higher efficiency rate and lower parts replacement frequency.

Additionally, consider the versatility of the machine you choose. Industry surveys reveal that businesses prioritizing adaptability to various belt sizes and materials report an average increase in revenue of 15% due to the ability to cater to diverse customer needs. This adaptability can make a huge difference in staying competitive in a dynamic market.

Tips: Look for machines that offer customizable features or different layering techniques, as these can help maintain flexibility in your production line.

When selecting a rubber belt layering machine for your business, evaluating brand reputation and customer support is crucial. According to a recent industry report from MarketsandMarkets, the rubber machinery market is projected to reach $6.9 billion by 2026, reflecting a growing trust in established brands that deliver reliability and innovation. Companies with robust reputations often have a history of durability and efficiency, which can significantly influence your operational success. Research shows that brands recognized for quality can reduce downtime by up to 30%, a crucial factor in maintaining productivity in competitive environments.

Moreover, customer support plays a vital role in the long-term satisfaction with your machinery investment. A survey by IndustryWeek reveals that 85% of manufacturers prioritize customer service and support when choosing equipment providers. Rapid response times and comprehensive technical assistance can minimize operational disruptions and enhance user experience. Brands that offer extensive warranties and quick access to replacement parts typically see higher customer retention rates, with statistics indicating a 50% increase in repeat purchases when customers feel supported. Therefore, meticulous research into a brand’s service metrics can lead to informed purchasing decisions that align with your business needs.

When selecting a rubber belt layering machine, customization can significantly enhance its performance to meet specific business needs. Different industries have varying requirements, and a one-size-fits-all approach may fall short. Customization options can include adjustable layering speeds, various belt widths, and the ability to handle different rubber materials. By fine-tuning these features, businesses can optimize their layering processes, maximizing efficiency and output.

Furthermore, the integration of advanced technologies such as automation and precision control can be tailored to suit specific operational demands. Features like programmable settings allow operators to maintain consistent quality while adapting to changing production volumes. Exploring these customization options not only enhances the machine’s performance but also provides businesses with a competitive edge in the ever-evolving market. Investing in a rubber belt layering machine that can be tailored to your unique requirements ensures that your operations remain agile and responsive to customer needs.