When it comes to manufacturing belts and straps, the right equipment can make all the difference. A Belt Strap Cutting Machine is an essential tool for businesses in the leather, textile, and synthetic material industries, allowing for precision cutting that meets specific design requirements. With various models available, choosing the best machine to suit your needs involves careful consideration of several factors, including cutting speed, size, material compatibility, and ease of use.

In today's competitive market, efficiency and quality are paramount. A well-selected Belt Strap Cutting Machine not only enhances productivity but also ensures consistency in the final product. Understanding the features and capabilities of different machines will empower manufacturers to make informed decisions, optimizing workflow and reducing waste. As we explore the key considerations for selecting a Belt Strap Cutting Machine, we will highlight the critical aspects that can guide you in finding the perfect fit for your production line.

When choosing a belt strap cutting machine, it's essential to understand the different types available, as each serves distinct manufacturing needs. Firstly, manual belt cutting machines are ideal for small-scale operations or workshops. They offer greater flexibility and control, allowing operators to cut materials to precise dimensions with minimal setup. These machines typically require more physical labor but are cost-effective and easy to maintain.

On the other hand, automatic belt strap cutting machines are designed for high-volume production environments. These machines increase efficiency by automating the cutting process, which reduces wasted material and enhances precision. They can handle various types of materials, from leather to synthetic straps, and are equipped with advanced features such as programmable settings and safety mechanisms. Understanding your production requirements and the materials you will be working with will help you decide between manual and automatic options.

Lastly, there are specialized machines available for specific applications, such as multi-layer cutting machines or those equipped with laser technology for intricate designs. These machines can fulfill niche market demands and improve the overall quality of the final product. By considering both your operational scale and the specific capabilities needed, you can select a belt strap cutting machine that best aligns with your production goals.

When selecting a belt strap cutting machine, several key features should be taken into account to ensure you are investing in the right equipment for your needs. First and foremost, the cutting precision of a machine is critical. Machines that can achieve cutting tolerances of less than 0.5 mm are often preferred, particularly in industries where high-quality finishes are essential. According to a market report by ResearchAndMarkets, the demand for precision cutting machines has surged by over 20% in the past five years as businesses seek to enhance their production efficiency while minimizing waste.

Another important consideration is the material compatibility of the cutting machine. Depending on the type of belt material—be it leather, synthetic fibers, or textiles—it is crucial to choose a machine that can handle specific thicknesses and materials without compromising on performance. Data from IBISWorld indicates that companies utilizing versatile cutting technologies can optimize their production processes and expand their product offerings, thus gaining a competitive edge in the market.

Finally, the ease of operation and maintenance cannot be overlooked. Machines with user-friendly interfaces and automated features tend to reduce the learning curve for operators, thereby improving productivity in the long run. Additionally, selecting a machine with comprehensive support and service options can minimize downtime, which is a vital factor in maintaining continuous production flow. Reports show that businesses with regular maintenance schedules reduce unexpected breakdown risks by approximately 30%, which highlights the importance of considering long-term operational efficiency when making a purchase decision.

When selecting the best belt strap cutting machine, assessing your production needs is paramount. The right machine should align with your manufacturing volume and the specific requirements of your production process. According to a report by MarketsandMarkets, the global demand for cutting machines in the leather goods sector is projected to grow at a CAGR of 6.5% from 2023 to 2028, driven by increasing automation in manufacturing processes. Understanding your production capacity—whether you require a machine that can handle small batch sizes or large-scale operations—will significantly influence your choice.

In addition to production volume, it's crucial to consider the types of materials you'll be working with. Different cutting machines offer varying capabilities, such as laser cutting or die cutting, suited for diverse materials like leather, synthetic fabrics, or heavyweight textiles. The 2022 Leather Industry Global Outlook reported that the increasing complexity of designs has led manufacturers to invest in versatile cutting solutions that can efficiently adapt to changing styles and materials. By identifying the types of materials and designs you regularly work with, you can choose a machine that not only meets your current demands but also allows for future scalability and innovation in your production line.

| Feature | Description | Production Need Level | Recommended Machine Type |

|---|---|---|---|

| Cutting Speed | The speed at which the machine can cut material. | High Demand | High-Speed Automated Machine |

| Material Compatibility | Types of materials the machine can cut. | Versatile | Multi-functional Machine |

| Precision | Accuracy of cuts made by the machine. | High Precision | Laser Cutting Machine |

| Ease of Use | How user-friendly the machine is. | Beginner Friendly | User-Friendly Manual Machine |

| Maintenance Requirements | Frequency and ease of machine maintenance. | Low Maintenance | Durable Industrial Machine |

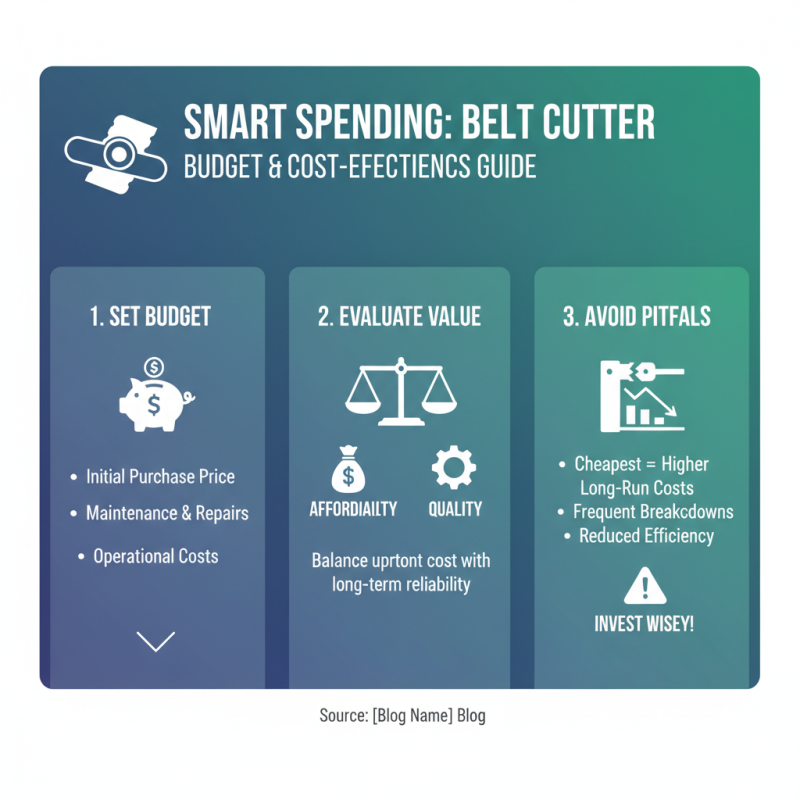

When selecting the best belt strap cutting machine, evaluating budget and cost-effectiveness is crucial to making an informed decision. Start by establishing a clear budget that encompasses not only the initial purchase price but also potential ongoing costs such as maintenance, repairs, and operational expenses. It’s essential to balance quality with affordability; opting for the cheapest option may lead to higher costs in the long run due to frequent breakdowns or inefficiencies.

Additionally, consider the machine's productivity and how it aligns with your business needs. Investing in a more advanced model might require a larger upfront cost, but if it significantly increases output and reduces labor costs, the initial investment could be justified. Analyze the cost per unit produced and the machine's longevity as these factors will play a pivotal role in determining its overall cost-effectiveness. By closely examining these aspects, you can choose a cutting machine that not only fits your financial situation but also aids in maximizing efficiency and productivity in your operations.

When selecting a belt strap cutting machine, it is essential to consider maintenance and support to ensure its longevity and optimal performance. Regular maintenance routines, such as cleaning, lubricating moving parts, and checking for wear, can prevent small issues from escalating into costly repairs. Establishing a schedule for these routine checks not only enhances the machine's lifespan but also keeps it functioning at its best, leading to consistent production quality. It's advisable to have clear guidelines on how to perform these maintenance tasks and to educate all operators on best practices.

Moreover, support considerations play a pivotal role in the successful operation of your cutting machine. Evaluate the availability of technical support and customer service from the manufacturer or supplier. A reliable support system ensures quick problem resolution, reducing downtime in production. It's beneficial to look for suppliers that provide comprehensive training, detailed operational manuals, and prompt assistance to address any potential issues. By prioritizing these maintenance and support factors, you can maximize the efficiency of your belt strap cutting machine and invest in its long-term productivity.