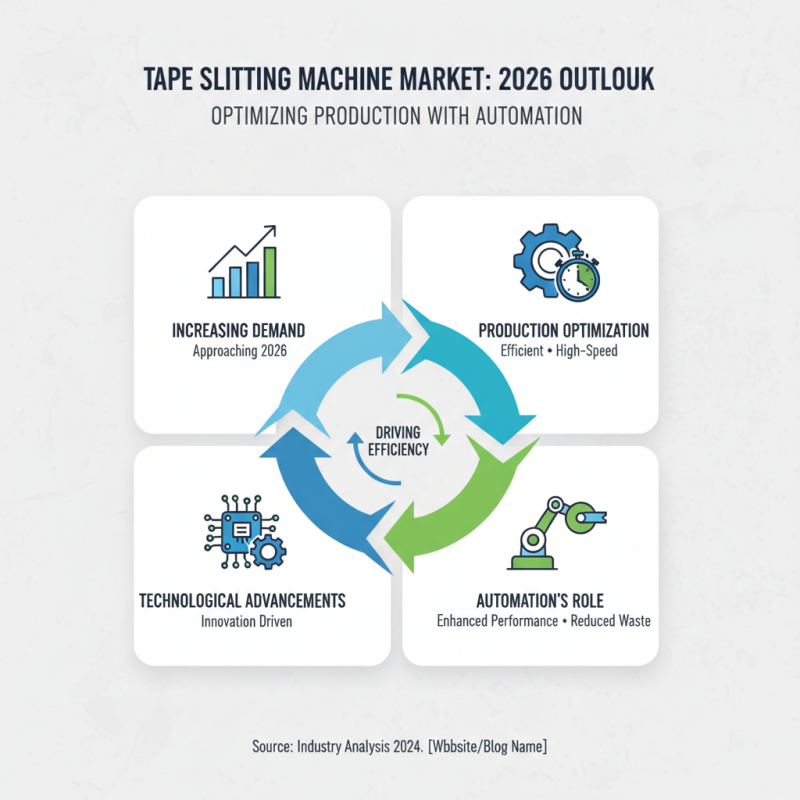

The demand for efficient manufacturing solutions has skyrocketed in recent years. The Tape Slitting Machine market is no exception. According to a recent industry report by Global Market Insights, the demand for slitting machines is expected to grow at a CAGR of 6.5% from 2022 to 2026. This growth is driven by advancements in technology and increasing applications across various sectors.

Dr. Emily Harper, a leading expert in tape slitting technology, states, "Choosing the right Tape Slitting Machine can significantly enhance production efficiency." The market is flooded with options, making it essential to understand key features like blade quality, precision, and speed. Many users overlook maintenance needs, which can lead to suboptimal performance over time.

Investing in a high-quality Tape Slitting Machine is crucial, yet many businesses still settle for subpar equipment. This can affect overall production and costs. Understanding what to look for is vital. Balancing price with features is often challenging, but necessary for making a wise investment.

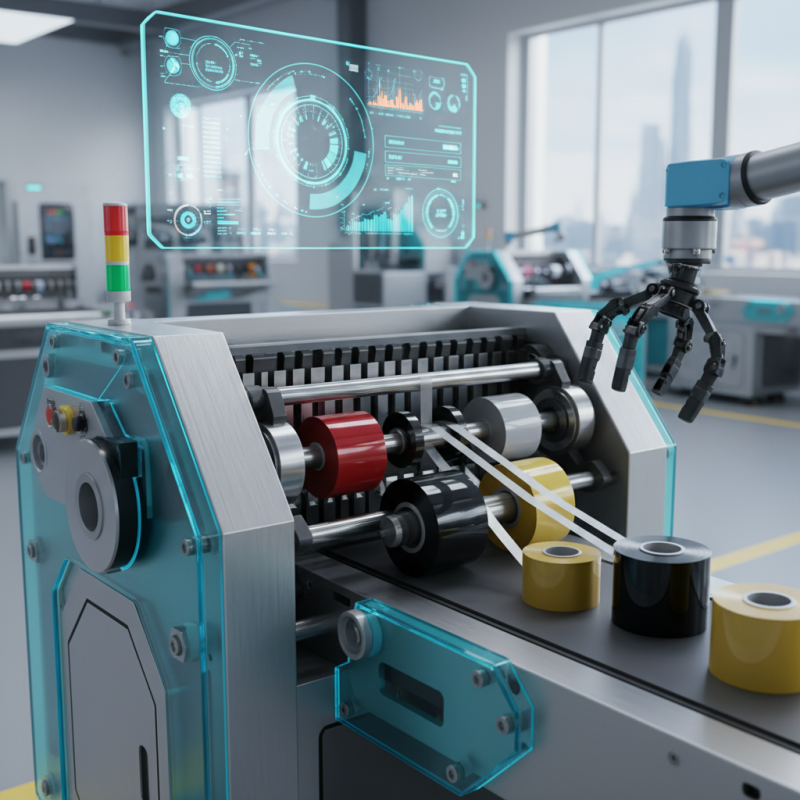

Tape slitting machines play a crucial role in the packaging industry. They cut large rolls of tape into smaller, more manageable sizes. This process is essential for companies that need specific tape dimensions for their products. A well-functioning tape slitting machine can significantly increase efficiency in production lines.

The need for precision is vital. Poorly slit tape can lead to waste. If the width is inconsistent, it creates issues downstream. Maintaining quality control is necessary. Regular checks on machine calibration can prevent costly errors. Industries rely on these machines to keep up with demand. Rushed operations can overlook maintenance, causing breakdowns. This can delay production timelines and increase costs.

Another aspect to consider is the adaptability of the tape slitting machine. Various tape types require different slitting techniques. Flexibility in machine capabilities can enhance productivity. However, not all machines deliver on this requirement. Buyers must evaluate their specific needs carefully. Each choice reflects on the overall effectiveness of their packaging operation.

When choosing a tape slitting machine, several key features stand out. First, consider the machine's speed. A faster machine increases productivity but may compromise precision. Balance is essential.

The cutting width is another critical aspect. It determines how versatile your machine will be. A narrow width might limit applications. However, a wider cutting capacity can be costly. Think about your specific needs.

Maintenance is vital too. Some machines require more upkeep than others. Regular maintenance can extend the machine's lifespan, but it can be time-consuming. Evaluate if you have the resources for this.

**Tips:** Look for user-friendly controls. Complex systems might slow you down more than you expect. Also, consider the durability of the components. Low-quality parts can lead to frequent repairs. An unplanned breakdown can disrupt operations significantly. Always double-check specifications before making a decision.

When selecting a tape slitting machine, industry standards and certifications play a crucial role. These certifications ensure that the machinery meets safety and performance requirements. Look for machines that comply with ISO standards. Such compliance indicates reliability and excellence in manufacturing. It’s also wise to check for CE marking, particularly in Europe. This certification ensures that the product meets EU safety standards.

Tips: Verify the machine's operational efficiency. A certified machine may still have varied performance ratings. Always compare different models. Robust testing reports can provide insight into their durability and performance under pressure.

Additionally, familiarizing yourself with regulatory requirements in your region is essential. Some areas have specific safety measures. Ignoring these can lead to operational setbacks. Remember to consider machine compatibility with existing workflows. Sometimes, certified machines can be complex or bulky. Reflect on whether your workspace can accommodate such a machine without compromising efficiency or safety.

Emerging technologies in tape slitting are transforming the industry. Companies are looking to enhance efficiency, speed, and precision. Innovations are making machines faster while reducing waste. This is crucial as industries now demand high-quality output in less time.

One significant development is the integration of AI. Machines equipped with AI can analyze patterns and adjust settings in real-time. This means less downtime and fewer errors. However, these systems require regular updates and training. The challenge lies in ensuring operators are well-versed in these technologies. Consequently, companies may face a learning curve.

Automation is also on the rise. Automated tape slitting machines can operate independently, increasing production rates. The downside is the initial investment. Adopting such technology may strain budgets. Balancing costs with long-term gains is essential for sustainable growth. Businesses must reflect on their current capabilities before diving into automation.

As we approach 2026, the demand for tape slitting machines continues to increase. Businesses are looking for efficient ways to optimize production. Technological advancements are driving this trend. Automation plays a critical role in enhancing performance and reducing waste.

When considering a tape slitting machine, think about versatility. The ability to handle various tape types is essential. Look for models that support different widths and materials. This flexibility can significantly impact your production line.

**Tip:** Evaluate your current production needs. Identify potential growth areas. This can pave the way for better investments.

Market forecasts indicate a rising interest in eco-friendly solutions. Many manufacturers are prioritizing sustainability. Efficient machines that reduce energy consumption are gaining traction. It’s essential to balance efficiency with environmental impact.

**Tip:** Keep an eye on emerging technologies. Some innovations may not meet expectations. Critical assessment is necessary. Not all new features will enhance productivity. Make informed choices to avoid potential pitfalls.