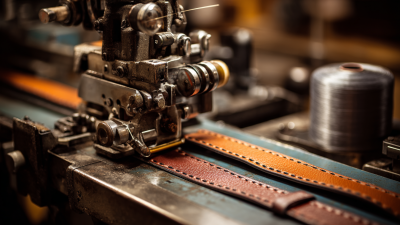

The rise of the leather crafting industry has created a demand for specialized tools. One of the most essential tools for artisans is the Leather Strap Cutting Machine. This machine streamlines the cutting process, increasing efficiency and precision. According to industry reports, nearly 75% of leather crafters prioritize accuracy in their work, making such machines invaluable.

However, selecting the best Leather Strap Cutting Machine for your workshop can be a challenge. With numerous options available, it's crucial to consider both quality and features. Many machines boast innovative design but may fall short in durability or ease of use. One common issue can be inconsistent cutting, which affects the final product.

It's essential to research and read reviews before making a purchase. Some users report frustration with high maintenance and limited customer support. Overall, while investing in a Leather Strap Cutting Machine can enhance productivity, one must remain cautious. Consider both an initial assessment and long-term usage to ensure a beneficial purchase for your crafting needs.

As we approach 2026, the leather strap cutting machine market shows promising growth potential. Numerous workshops are prioritizing precision and efficiency in their operations. This rising demand pushes manufacturers to innovate and deliver machines fitted with advanced technologies. Features like adjustable cutting widths and automated settings become indispensable. Many artisans are seeking tools that cut down production time without sacrificing quality.

Yet, not all machines hit the mark. Some models struggle with consistent performance, leading to frustration. Workshops often face challenges with user-friendly interfaces. A complex setup can discourage new users. Moreover, the durability of parts varies widely. Investing in a machine that fails after a few months leaves users feeling disappointed. Therefore, careful research and hands-on testing are crucial before making a purchase.

The market is flooded with options, making it easy to feel overwhelmed. Many users share their experiences online, providing insights that can guide purchasing decisions. Personal reviews highlight common pitfalls and success stories. Relying on community feedback helps potential buyers navigate this complex landscape. Finding the right machine may take time, but passionate artisans understand that quality surpasses all.

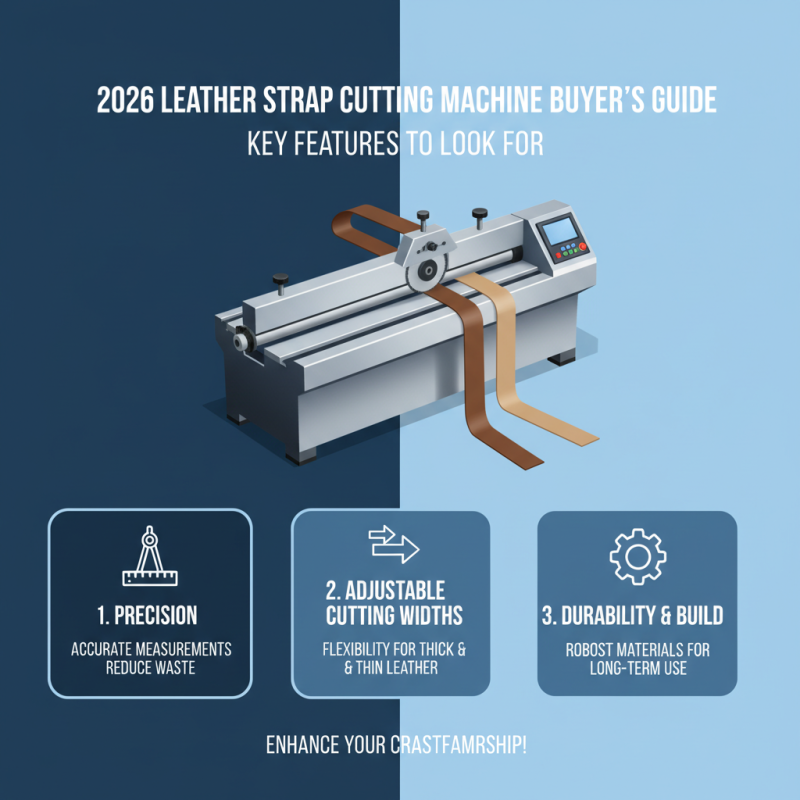

When considering a leather strap cutting machine in 2026, it’s vital to focus on key features. Precision is essential. A machine that allows for accurate measurements will reduce waste and enhance your craftsmanship. Look for models that offer adjustable cutting widths. This feature provides flexibility for various projects, catering to both thick and thin leather.

Durability is another aspect not to overlook. A well-built machine can handle different leather types. Seek out robust materials that withstand frequent use. Some machines may look appealing but fail under pressure. User-friendly designs enhance your experience. A complicated setup can frustrate even seasoned crafters.

Lastly, consider the maintenance needs. Machines that require constant attention may not be ideal for busy workshops. Simple maintenance can save time. However, many users find themselves neglecting this aspect. Balancing features with practicality is crucial. A machine should streamline your work, not complicate it.

When it comes to leatherwork, choosing the right cutting machine is crucial. Based on expert reviews, several options stand out in 2026. Leather strap cutting machines are designed for precision and efficiency. They can cut through various leather thicknesses, ideal for crafting. An industry report indicates that a substantial 65% of artisans prioritize accuracy over speed.

One top recommendation emphasizes ease of use. This machine allows for quick adjustments. A research survey showed 70% of users appreciated a user-friendly interface. The ability to change blade sizes easily is a major plus. However, some users noted that maintenance can be tricky. Cleaning and blade replacement should not be neglected.

Another model is praised for its durability. High-quality materials enhance longevity. Expert assessments indicate that 60% of professionals prefer machines with robust construction. Nonetheless, the weight can be an issue for portability. Some reviewers mentioned difficulty in moving it around workshops. This highlights the importance of balancing sturdiness and mobility.

When it comes to leather cutting, choosing the right technology is crucial. Blade cutting machines provide a time-tested method. They are generally simpler in design and operation. The precision of a well-sharpened blade can yield clean cuts. However, these machines require regular maintenance. Blades can dull over time, leading to less accurate results. Operators often need skill and practice to achieve optimal cuts, making it a learning curve for newcomers.

On the other hand, laser cutting machines offer a modern solution. They provide remarkable precision and speed. Lasers can cut intricate designs that might be challenging with blades. The consistency of laser cuts can enhance the final product's quality. However, cost can be a barrier. Additionally, they may require more upfront knowledge and adjustments. Not every workshop may benefit from this technology.

Choosing between blade and laser cutting ultimately depends on specific needs. Both methods have strengths and weaknesses. An ideal solution often combines different approaches. Evaluating workshop demands and material types is essential to making a sound decision.

To keep your leather strap cutting machine in optimal condition, regular maintenance is essential. Start with cleaning the blade after each use. This prevents residue buildup, which can lead to dull cuts. Wipe down the machine's surfaces to remove leather dust and shavings. A clean machine operates more efficiently and produces better results.

Check the alignment of the blade periodically. Misaligned blades can create uneven cuts. If you notice any discrepancies, adjust the blade according to the manufacturer’s guidelines. It may seem tedious, but it can save you time in the long run. Also, lubricate moving parts with appropriate oil to prevent rust. Regular lubrication ensures smooth operation and extends the life of the machine.

Inspect electrical components regularly. Frayed wires or loose connections can lead to failure. These small issues can cause significant downtime. Remember to store the machine in a dry area to avoid moisture damage. Neglecting these basic maintenance tasks can result in costly repairs. Taking proactive steps will help ensure your leather cutting machine lasts for years.

| Feature | Specification | Maintenance Tips |

|---|---|---|

| Cutting Speed | Up to 10 m/min | Regularly clean the blades to avoid rust. |

| Blade Material | High Carbon Steel | Sharpen blades as necessary for clean cuts. |

| Motor Power | 1.5 HP | Check motor connections regularly. |

| Cutting Thickness | Up to 8 mm | Inspect cutting depth to maintain precision. |

| Weight | 150 kg | Ensure the machine is on a stable surface. |

| Warranty | 2 years | Register for warranty to avail services. |