In the world of leather crafting, the efficiency and precision of the tools you choose can make a significant difference in the quality of your final product. "When selecting a Leather Belt Strap Cutting Machine, it's essential to consider not only the technology but also how it aligns with your specific production needs," says John Smith, a renowned expert in leather machinery. His insights highlight the growing importance of modern cutting machines in enhancing productivity and precision in the leather belt manufacturing process.

With the vast array of Leather Belt Strap Cutting Machines available today, making the right choice can be daunting for both seasoned artisans and newcomers alike. This guide will delve into the top five tips for choosing the best machine that not only meets your requirements but also elevates your craftsmanship. By understanding the key features and functionalities that matter most, you can invest in a machine that will optimize your leather cutting processes and ultimately lead to higher quality products. The right Leather Belt Strap Cutting Machine is not just a tool; it’s a crucial investment for your creative and business success.

When exploring the world of leather belt strap cutting machines, it's essential to understand the various types available, as each serves a unique purpose based on specific manufacturing needs. The two primary categories of cutting machines are manual and automatic.

Manual machines offer simplicity and control, allowing artisans to precisely cut leather for custom designs. They are ideal for small-scale production or hobbyists who prioritize craftsmanship and personal touches in their work.

On the other hand,

automatic leather belt strap cutting machines are designed for efficiency and mass production. These machines typically feature advanced technology that enables them to cut multiple leather pieces simultaneously, significantly reducing production time. While they may require a higher initial investment, the long-term benefits in productivity and consistency can be substantial for larger businesses. Understanding these differences is crucial when selecting the right machine, as it directly impacts the overall efficiency and quality of leather belt strap production.

When selecting a leather belt strap cutting machine, several key features play a crucial role in ensuring efficiency and quality. Firstly, precision is paramount. Look for machines equipped with high-quality cutting mechanisms that provide consistent and accurate cuts. This ensures that each belt strap maintains uniform width and shape, which is essential for producing professional-grade products. Additionally, adjustable settings for various thicknesses of leather can enhance versatility, allowing you to work with different materials seamlessly.

Another vital feature to consider is the machine's ease of use. User-friendly controls and clear instructions are important for achieving optimal results without complications. Machines with automated feeding systems can save time and reduce manual effort, contributing to a more streamlined workflow. Furthermore, durability and maintenance needs should not be overlooked. A well-constructed machine will withstand heavy use and provide longevity, while those that require minimal maintenance will enhance productivity in the long run. Investing in a cutting machine that combines these features will significantly elevate your leather crafting experience.

In this chart, we illustrate the key features to consider when selecting a leather cutting machine, including precision, speed, durability, and user-friendliness.

When selecting a leather belt strap cutting machine, one of the most crucial factors to consider is the brand reputation and customer reviews. Brands with a longstanding presence in the market tend to have established credibility, which can be a good indicator of quality and reliability. Researching the brand's history and its experience in manufacturing leather cutting machines can provide insights into their commitment to innovation and customer satisfaction. A reputable brand is more likely to offer robust customer support and reliable warranties, adding to the overall value of your investment.

In addition to brand reputation, delving into customer reviews is essential for making an informed decision. Analyzing feedback from users who have firsthand experience with the machine can reveal valuable insights regarding its performance, durability, and ease of use. Look for consistent themes in the reviews, such as mentions of build quality, efficiency, and specific features that set the machine apart from others. This real-world feedback can help identify potential challenges and advantages, ultimately guiding you toward a machine that best meets your needs in leather cutting projects.

When evaluating leather belt strap cutting machines, understanding the relationship between price and performance is crucial for making an informed decision. Data from industry reports indicate that the average price range for high-quality cutting machines falls between $2,000 to $10,000, depending on features such as precision, speed, and durability. Machines that offer advanced features, like automatic operation and programmable settings, can enhance productivity but may also come with higher upfront costs. It is essential for buyers to consider how frequently they will utilize the machine and the volume of production required to determine if the investment aligns with their operational needs.

Performance metrics, such as cutting speed and accuracy, play a significant role in overall machine efficiency. Industry analysis shows that machines capable of achieving cutting speeds of up to 30 meters per minute can significantly reduce production time, making them favorable for businesses with high throughput. Moreover, machines that maintain a precision tolerance of ±0.5 mm ensure that the finished product meets quality standards, minimizing waste and rework costs. Overall, the best choice is one that strikes a balance between operational performance and cost-effectiveness, allowing businesses to maximize their return on investment while meeting customer demand for high-quality leather products.

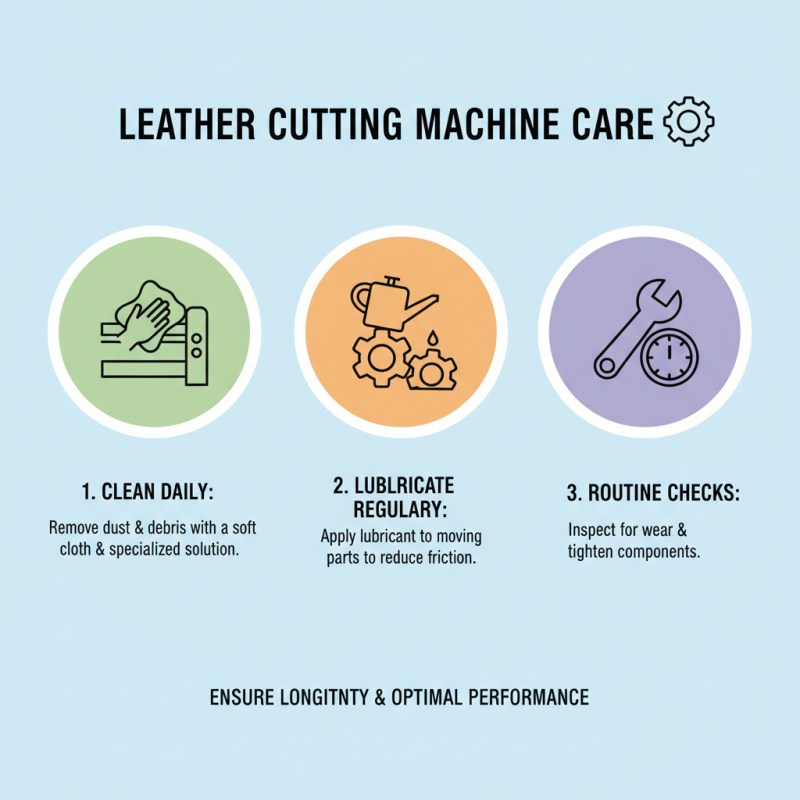

Maintaining a leather cutting machine is essential for ensuring its longevity and optimal performance. Regular maintenance routines should include cleaning the machine after each use to prevent dust and leather debris from accumulating in the components. It's advisable to use a soft cloth and appropriate cleaning solutions to avoid damaging the machine's surfaces. Additionally, lubricating moving parts at regular intervals minimizes friction and wear, ultimately extending the machine's operational life.

Another crucial aspect of maintenance is routine inspection of critical components such as blades and gears. Dull blades can lead to uneven cuts and increased stress on the machine, so sharpening or replacing these parts promptly can improve efficiency and prevent further damage. Ensure that all bolts and screws are tightly secured, as vibrations during operation can cause them to loosen over time. Following these maintenance practices not only enhances the machine’s performance but also safeguards your investment in the long run.