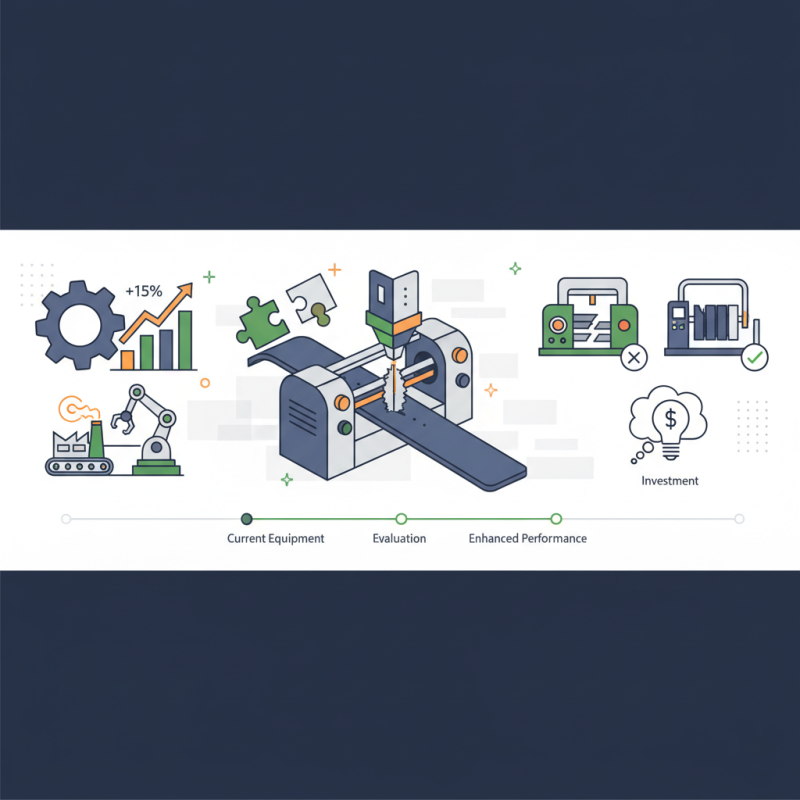

The demand for precision in manufacturing has never been higher, particularly in the belt strap cutting industry. A recent industry report indicates that the market for Belt Strap Cutting Machines is projected to grow by 15% over the next five years. This growth is driven by increased automation and the need for higher efficiency in production lines. However, some manufacturers still struggle with outdated machinery that hinders their potential.

Expert John Anderson, a leader in industrial cutting technology, states, “Investing in a modern Belt Strap Cutting Machine can significantly enhance output and reduce waste.” Many companies overlook the importance of precision tools, leading to inaccuracies that could affect overall productivity. Choosing the right machine is not just about cost; it’s about investing in long-term efficiency.

The right cutting machine ensures clean, precise cuts that meet rigorous standards. Nonetheless, with many options available, evaluating features can be overwhelming. Some machines may promise high efficiency but fail to deliver on quality. This creates an opportunity for companies to reflect on their current equipment and make informed decisions for better performance in their operations.

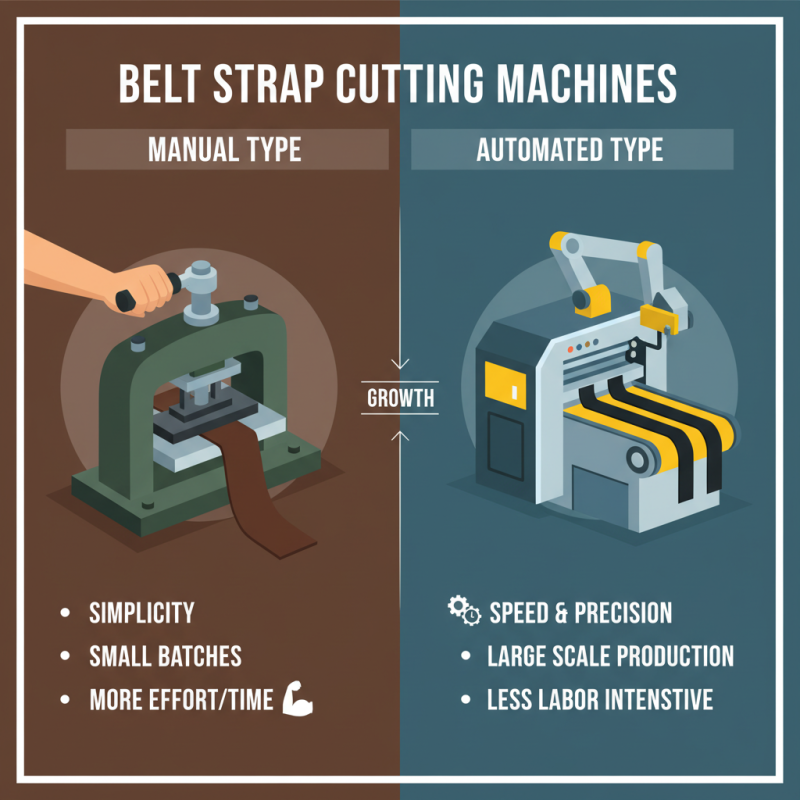

When selecting a belt strap cutting machine, various types are available to consider. Manual machines offer simplicity and control. They are ideal for small projects or businesses. However, manual options require more effort and time. Users may find these machines less efficient for larger tasks.

Automatic belt strap cutting machines provide speed and precision. They can handle large volumes, reducing labor costs. This option is suitable for industries needing high output. However, users must maintain these machines frequently. Failure to do so can lead to breakdowns, affecting productivity.

**Tips:** Always evaluate your specific needs before choosing a machine. Consider the types of materials you'll cut and the volume required. Investing in professional training for employees can enhance efficiency. Regular maintenance checks can prevent costly repairs. Balancing cost with quality is essential for long-term success. Choosing the right machine enhances both precision and efficiency in cutting belt straps.

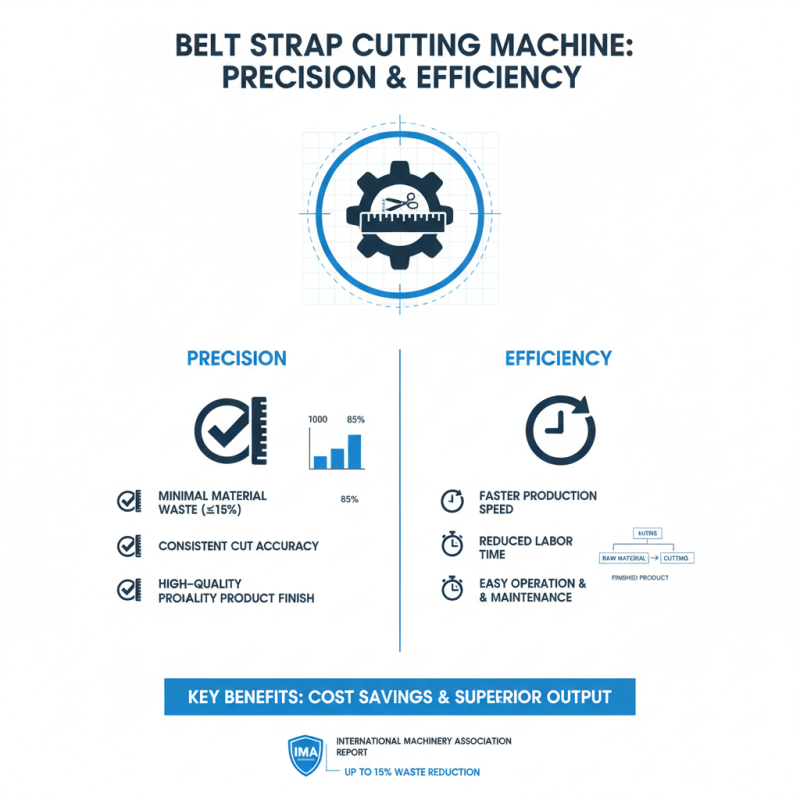

When selecting a belt strap cutting machine, precision and efficiency are crucial. In industries requiring high-quality products, a machine's cutting accuracy can significantly influence the final output. A recent report by the International Machinery Association highlighted that inaccuracies in cutting can result in up to 15% material waste. This emphasizes the need for reliable equipment that ensures precise cuts with minimal waste.

Key features to look for include adjustable cutting speeds. Machines with variable speeds can adapt to various materials and thicknesses. This adaptability can enhance cutting efficiency. Additionally, machines equipped with advanced sensors can improve precision by detecting material variations in real-time. It’s reported that companies utilizing such technologies see a 20% increase in production efficiency.

Another aspect to consider is the machine’s ease of maintenance. Frequent downtime for servicing can disrupt workflows. A user-friendly interface and accessible components can save time. Yet, not all machines are created equal. Sometimes, users face challenges with software integration or ergonomic design. Therefore, it is vital to choose a machine that combines technology with practical usability.

Belt strap cutting machines are vital for precision in manufacturing. They streamline the process of cutting materials like leather, fabric, or synthetic materials. Efficient machines improve productivity. However, not all machines operate the same way. Some struggle with thicker materials, causing delays and errors. It’s essential to evaluate each model’s capabilities before investing.

Efficiency depends on speed and accuracy. A good machine should cut precisely without fraying the edges. Operators often face challenges with blade dullness. A dull blade can lead to inaccuracies. This can waste time and material. Maintenance is crucial. Regular checks can help prolong the life of cutting blades.

Considering the overall design is also important. Some machines are bulky and hard to maneuver. This can affect workflow, slowing down production. Furthermore, user training is often overlooked. An untrained operator can miss nuances in machine settings. This may result in wasted resources and increased costs over time. Understanding these factors can lead to better decision-making for businesses.

| Model | Cutting Speed (m/min) | Max Cutting Thickness (mm) | Precision (mm) | Power Consumption (kW) |

|---|---|---|---|---|

| Model A | 25 | 5 | 0.1 | 3.0 |

| Model B | 30 | 6 | 0.05 | 4.5 |

| Model C | 20 | 4 | 0.15 | 2.5 |

| Model D | 35 | 7 | 0.08 | 5.0 |

When searching for the best belt strap cutting machines, precision and efficiency are crucial factors. Numerous reports highlight that the quality of the cutting process significantly affects production rates. For example, companies using high-performance cutting machines reported a 30% increase in output compared to those with outdated technology.

Top models often feature advanced cutting capabilities. Look for machines that utilize high-speed blades for clean cuts. Some machines can handle various belt materials, enhancing versatility. Additionally, models with programmable settings ensure that you can replicate cuts with high precision, reducing waste.

**Tips**: Regular maintenance is essential. A well-maintained machine operates more efficiently. Avoid long downtimes by checking the cutting parts frequently. It’s also beneficial to provide training for operators to minimize errors during the cutting process.

In selecting machinery, reflect on the learning curve involved. Some high-tech models require time to master. Consider the experience of your team and their comfort with complex machines. A balance between technology and user-friendliness can lead to better outcomes.

Belt strap cutting machines can significantly enhance productivity. However, maintaining these machines is crucial for optimal performance. Regular checks on blades and cutting surfaces help ensure precision. Dull blades can compromise the quality of cuts. Regularly replacing them is necessary. A sharp blade will produce cleaner edges and reduce material wastage.

Troubleshooting issues is another key aspect of maintaining these machines. Odd noises during operation may indicate misalignment. Vibrations can be a warning sign, signaling that something is off. Ignoring these signals may lead to bigger problems. Simple adjustments can often resolve minor issues. Regularly cleaning components helps prevent build-up that impairs functionality. Dust and debris can affect the machine's performance, leading to uneven cuts.

Monitoring the machine's performance metrics is vital for operational efficiency. Inconsistencies in cutting lengths can point to mechanical problems. Tracking these discrepancies can uncover patterns that require attention. Even with the best machines, human error can play a role. Operators must stay alert and disciplined to catch potential mistakes early. Regular training can also sharpen skills and improve outcomes.