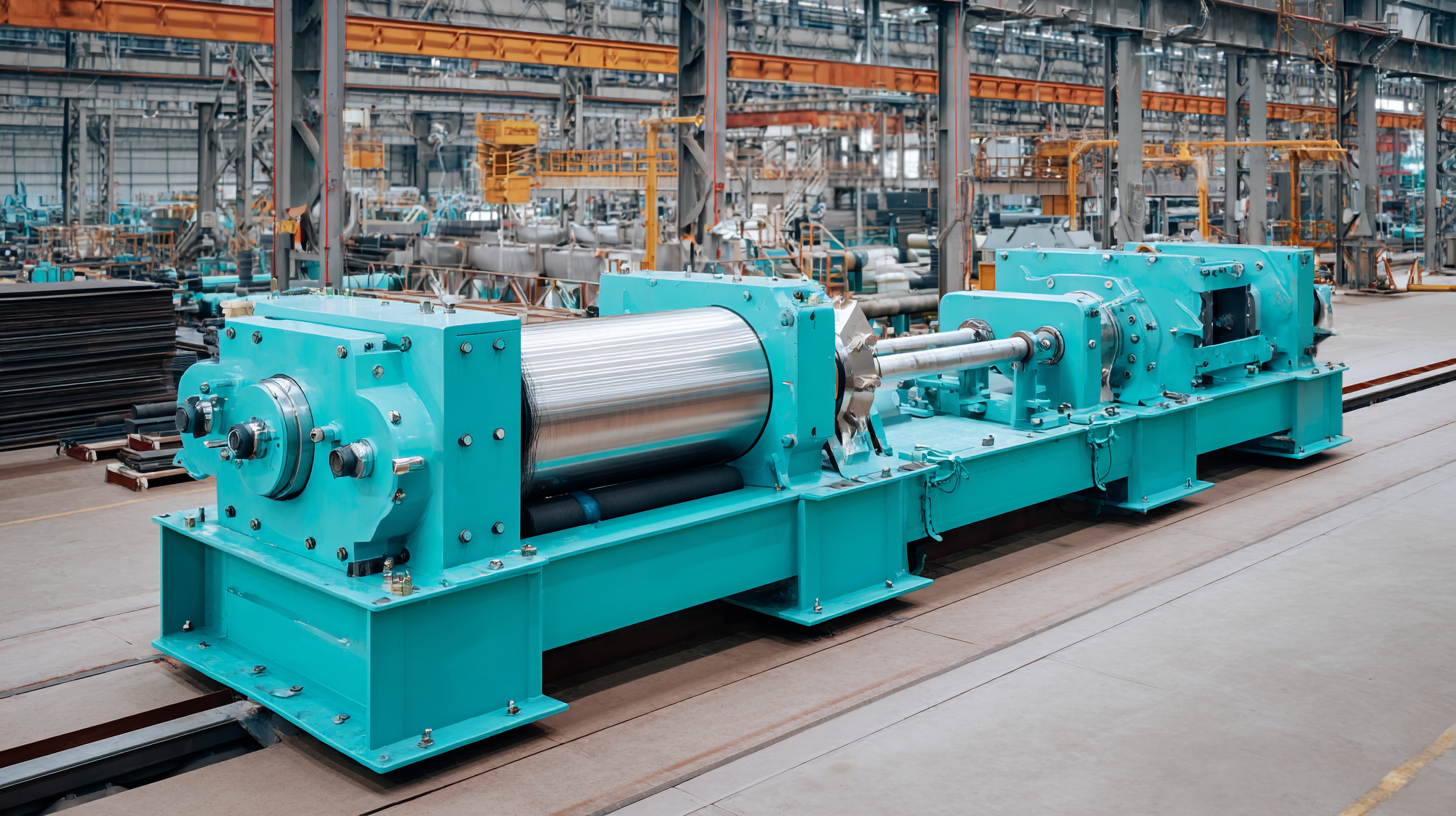

In the ever-evolving landscape of modern industry, the adoption of innovative machinery plays a pivotal role in enhancing operational efficiency and productivity. Among these advancements, the Rubber Belt Traction Machine stands out as a crucial component in various sectors, from manufacturing to transportation. Designed to optimize the movement and handling of materials, this machine employs flexible rubber belts that provide superior grip and traction, significantly reducing slippage and wear. As industries increasingly focus on automation and safety, understanding the benefits of Rubber Belt Traction Machines becomes essential for businesses aiming to improve their logistical capabilities and streamline their processes. This guide will explore the advantages of utilizing these machines, offering insights into how they can transform industrial operations and contribute to greater overall success.

Rubber belt traction machines have become integral to modern industrial applications, primarily due to their exceptional operational efficiency. These machines utilize flexible rubber belts that provide high friction and grip, allowing for smoother transfers of heavy loads and materials. By minimizing slippage and increasing the contact surface, rubber belt systems enhance the reliability and speed of production processes, making them ideal for various industries, such as manufacturing, logistics, and mining.

The operational efficiency of rubber belt traction machines is further amplified by their ability to adapt to different working conditions. They can operate effectively in environments with varying temperatures and humidity levels, which often affect traditional traction systems. Additionally, these machines are designed for easy maintenance, reducing downtime and enhancing productivity. Their versatility in handling diverse materials, shapes, and sizes makes them indispensable tools for industries aiming to optimize their operations and ensure a seamless flow of goods and resources.

In today's competitive manufacturing landscape, evaluating the cost-savings offered by rubber belt traction machines is essential for operational efficiency. These machines not only enhance productivity but also reduce downtime significantly. By utilizing rubber belts, industries can achieve smoother operations and minimize wear and tear on equipment. The resilience and flexibility of rubber ensure that traction machines can handle various loads and materials, which translates into fewer replacements and lower maintenance costs over time.

Moreover, the energy efficiency of rubber belt traction machines contributes directly to cost savings. Compared to traditional machinery, these systems often require less power to operate, leading to reduced energy bills. Additionally, their ability to smoothly transport materials minimizes the risk of product damage, further cutting costs associated with waste and rework. As manufacturers seek innovative ways to streamline processes, the integration of rubber belt traction machines stands out as a financially sound strategy, ultimately enhancing bottom-line results while maintaining high-quality production standards.

Rubber belt traction machines are rapidly gaining traction in modern industrial settings, particularly for their enhanced safety features. The design of these machines ensures that they operate smoothly with reduced slippage, which minimizes the risk of accidents that can occur from unexpected mechanical failures. By providing a consistent grip, rubber belts help to secure loads firmly, reducing the likelihood of injuries caused by heavy objects falling or shifting during transport.

**Tip:** Regular maintenance of rubber belt traction machines is critical. Ensure that you routinely inspect the belts for wear and tear, as this can significantly impact both performance and safety. Keeping the machinery clean and lubricated will extend its lifespan and prevent malfunctions.

Additionally, the non-slip and shock-absorbing qualities of rubber contribute to a safer working environment. They lower the vibrations transmitted through equipment, which not only protects the machinery but also enhances operator comfort. With the addition of safety features such as emergency stops and overload protection, users can confidently operate these machines knowing they are equipped with the necessary safeguards.

**Tip:** Invest in staff training focused on the safe operation of rubber belt traction machines. Education on proper handling techniques empowers employees to utilize the equipment effectively while prioritizing their safety and that of their colleagues.

This chart illustrates the safety improvements offered by Rubber Belt Traction Machines in various industrial settings. The data reflects the reduction of incidents over a five-year period in three different types of industries: manufacturing, construction, and logistics.

The adoption of rubber belt traction machines in modern industry is not only about enhancing operational efficiency but also addressing sustainability challenges. These machines significantly reduce energy consumption compared to traditional systems. According to the International Energy Agency (IEA), implementing advanced traction systems can lead to a 15-30% reduction in energy use in material handling processes. This transition is vital as companies increasingly prioritize eco-friendly practices to minimize their carbon footprint.

Moreover, the use of rubber belts over steel alternatives has profound environmental implications. Rubber belts are often lighter and less energy-intensive to produce, contributing to lower emissions during manufacturing. A report by the EPA indicates that switching to rubber belt traction systems can decrease greenhouse gas emissions by up to 20%, depending on operational scale. Such innovations not only enhance sustainability but also appeal to a growing consumer base prioritizing environmentally responsible companies.

Tips: When considering a switch to rubber belt traction machines, evaluate your current energy consumption and calculate potential savings. Additionally, research local suppliers of rubber materials that prioritize sustainable practices to amplify your environmental impact. Embracing this technology not only boosts operational efficiency but positions your business as a leader in sustainability.

Rubber belt traction machines have become indispensable in various key industries due to their efficiency and versatility. For instance, the manufacturing sector benefits significantly from these machines in transporting materials across production lines, enhancing productivity. Their ability to operate smoothly on uneven surfaces makes them ideal for mining and construction industries as well, where heavy loads and harsh environments are common. Performance metrics, such as load capacity and durability, highlight their superiority in these sectors, with many machines capable of withstanding extreme conditions while maintaining high operational efficiency.

**Tips:** When considering the integration of rubber belt traction machines, it's essential to evaluate the specific needs of your industry. Look for models with adjustable speed settings and load capacities that align with your operational requirements. Additionally, regular maintenance plays a crucial role in ensuring consistent performance and prolonging the lifespan of these machines.

In the agricultural sector, rubber belt traction machines facilitate the movement of heavy equipment and harvested products, reflecting their adaptability. Performance metrics such as fuel efficiency and maintenance frequency are crucial for evaluating the cost-effectiveness of these machines. The hydraulic systems used in many models also contribute to their powerful traction capabilities, making them an asset in plowing and harvesting applications.

**Tips:** Always consult with manufacturers about the specifications and best practices for maintenance to maximize efficiency and safety in your operations.

| Industry | Key Benefits | Performance Metric | Operational Efficiency (%) |

|---|---|---|---|

| Manufacturing | Increased durability and lower maintenance costs | Cycle Time Reduction | 85% |

| Mining | Enhanced traction and load handling | Payload Capacity | 90% |

| Agriculture | Improved soil protection and reduced slip | Soil Impact Minimization | 82% |

| Logistics | High efficiency in goods transportation | Delivery Time | 88% |

| Construction | Versatile applications across varied terrains | Operational Versatility | 87% |