When considering a Belt Strap Cutting Machine, understanding its features is essential. This type of machine is widely used in various industries, from fashion to automotive. Their efficiency in cutting straps can save time and resources.

Key features of a Belt Strap Cutting Machine include precision cutting, speed, and ease of use. The right machine should accommodate different strap materials, providing versatility. Buyers might struggle with options, leading to confusion. Yet, having a clear guide can simplify the process.

Investing in this equipment involves reflection. It’s important to assess not just the price, but also your specific needs. Quality machines are available, but not all are perfect. Each brand may offer unique functions that require careful consideration. Some choices may lead to regrets later.

When exploring the belt strap cutting machine, understanding industry standards is crucial. These machines vary in capabilities and specifications. Often, they are designed to handle different widths and materials. Precision is essential for creating high-quality straps that meet market demands.

Tips for selecting a machine include checking its cutting speed and accuracy. A reliable model should easily cut through various materials. Observe the machine's build quality. A sturdy construction usually translates to longevity.

Consider the machine's ease of use. A complicated interface can slow down production. Look for models with clear instructions and user-friendly features. This clarity can significantly impact efficiency. Explore user reviews too. They often highlight real-world performance and potential issues.

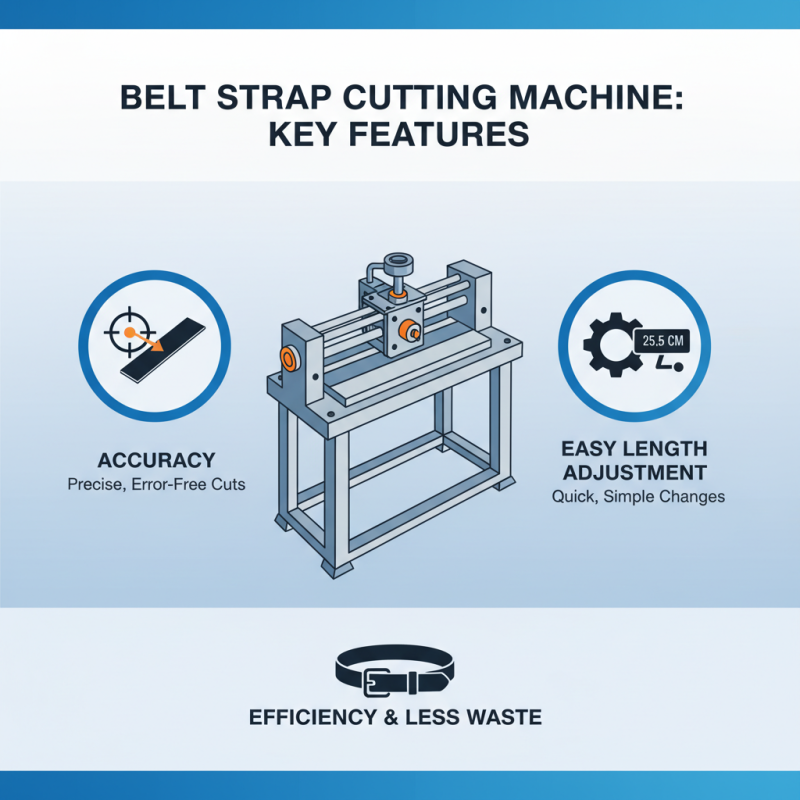

When looking for a belt strap cutting machine, several key features can greatly enhance your efficiency. Accuracy is vital. A machine should make precise cuts without error. This ensures your straps fit perfectly, reducing waste and saving time. Consider how easy it is to adjust cutting lengths. Manual adjustments can be tedious, leading to frustrations and potential mistakes.

Another important aspect is speed. A good machine should handle multiple straps quickly. If the production line is too slow, it may lead to delays. Look for machines with high-speed capabilities. Additionally, user-friendly controls can make a significant difference. Simple interfaces allow operators to focus on production rather than troubleshooting. Some machines may appear advanced but can be confusing to operate.

Lastly, durability matters. Machines made from high-quality materials will often last longer. Regular maintenance can prevent breakdowns, saving you from costly repairs. However, it’s important to reflect on your choices. Sometimes, tempting features may lead to overcomplicated operations. A balance between functionality and simplicity is essential for long-term success.

When considering cutting techniques, it's crucial to understand the options available. Different methods cater to various materials and project requirements. Common techniques include die cutting, laser cutting, and rotary cutting. Each has its unique advantages and limitations.

Die cutting is precise and ideal for specific shapes. It's commonly used in industrial settings. However, it can be costly and requires careful setup. Laser cutting offers high precision and can handle intricate designs. But it may not be suitable for thicker materials. Rotary cutting is fast and efficient for long materials, but it might lack the fine detail other methods provide.

Tip: Assess your material before choosing a cutting technique. The wrong choice can lead to wasted resources.

Choosing the right machine can be daunting. Not every machine fits every project. Understanding the materials you’ll work with is essential. For leather, a machine designed for thicker materials is necessary. But, for textiles, a more delicate approach is needed.

Tip: Experiment with samples first. This helps identify the best technique without committing to a large project. It’s a wise step to avoid costly errors.

When choosing a belt strap cutting machine, several factors come into play. The type of cutting mechanism is vital. Blades can vary in material and sharpness. A dull blade can lead to uneven cuts. This discrepancy may result in wasted materials and time. It’s crucial to consider the maintenance needs of the blades.

Speed is another essential feature. Some machines provide adjustable speeds, allowing for versatility. A slower speed may be ideal for intricate patterns. However, faster speeds can enhance production efficiency. Users often find themselves experimenting to find the perfect balance. Finding that sweet spot can be quite challenging.

The machine's size and portability matter too. A compact design may save space, but it could limit functionality. Conversely, a larger machine might offer more cutting options but could be cumbersome. Users should think about their workspace before making a decision. Reflecting on the intended use will help in choosing the right option.

When it comes to belt strap cutting machines, the market offers a range of options. A comparative analysis reveals significant variances in features among leading models. According to a recent industry report, nearly 45% of users prioritize cutting precision. Machines designed with advanced laser cutting technology perform exceptionally well in this area, minimizing material waste.

Durability is another crucial factor. A study showed that 65% of businesses consider the machine's build quality before purchase. Many popular choices employ high-strength materials, ensuring longevity. However, some models fall short of expectations, especially under heavy usage. This discrepancy can often lead to increased maintenance costs.

User experience varies significantly based on the machine's interface. Intuitive controls tend to enhance productivity. Yet, several users report frustrations with complicated setups that detract from operational efficiency. This feedback indicates a need for brands to refine user interfaces further. Prioritizing both functionality and user-friendly design is essential for improving satisfaction among operators.