In the rapidly evolving landscape of modern manufacturing, efficiency and precision are paramount, particularly in industries that require bulk bag handling and production. The advent of the Fibc Belt Cutting Machine has revolutionized the way manufacturers approach the cutting process, enabling them to achieve higher productivity rates while minimizing material waste. According to a report by Grand View Research, the global flexible intermediate bulk container (FIBC) market is projected to reach USD 5.4 billion by 2025, underscoring the increasing demand for innovative solutions within this sector. The integration of automated cutting technology not only streamlines operations but also enhances the overall quality of the final product. As manufacturers continue to seek competitive advantages, investing in a Fibc Belt Cutting Machine represents a crucial step toward modernizing production lines, ensuring consistency, and meeting the rigorous standards of today's market.

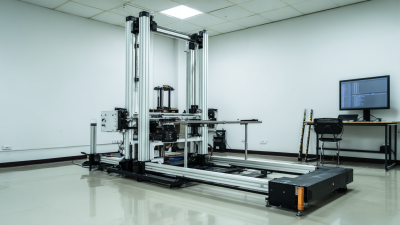

FIBC (Flexible Intermediate Bulk Container) belt cutting machines have become an essential asset in modern manufacturing, enabling businesses to streamline production processes and enhance efficiency. These machines are specifically designed to cut belts with precision, which is crucial when creating bags and containers that require specific dimensions and strength. The use of FIBC belt cutting machines not only reduces material waste but also minimizes labor costs by automating a task that historically involved manual labor.

FIBC (Flexible Intermediate Bulk Container) belt cutting machines have become an essential asset in modern manufacturing, enabling businesses to streamline production processes and enhance efficiency. These machines are specifically designed to cut belts with precision, which is crucial when creating bags and containers that require specific dimensions and strength. The use of FIBC belt cutting machines not only reduces material waste but also minimizes labor costs by automating a task that historically involved manual labor.

Tips: When integrating a FIBC belt cutting machine into your workflow, consider investing in training for your team to ensure they are well-versed in operating the equipment. This can lead to reduced errors and increased productivity over time. Additionally, regular maintenance of the machine can prevent costly downtime and prolong its lifespan.

Another significant advantage of these cutting machines is their adaptability to various materials and thicknesses. Manufacturers can select machines that accommodate their specific needs, whether they're dealing with woven polypropylene or other synthetic fibers. This versatility allows companies to maintain high standards of quality while responding rapidly to changing market demands.

Tips: Conduct a thorough assessment of your material types before purchasing a belt cutting machine to ensure you choose one that meets your requirements. It's also beneficial to review different models and their capabilities to find the best fit for your production needs.

In modern manufacturing, efficiency is paramount, and utilizing a FIBC belt cutting machine presents significant benefits. One of the primary advantages is the machine's precision in cutting. Traditional methods often lead to material wastage due to human error or inaccurate measurements. With the advanced technology of belt cutting machines, manufacturers can achieve consistent dimensions and reduce offcuts, thereby optimizing material usage and lowering production costs.

Another key benefit is the enhanced speed at which production can occur. FIBC belt cutting machines are designed for high throughput, allowing manufacturers to process large volumes of materials in a shorter timeframe. This acceleration in production not only meets the increasing demand but also enables companies to respond more swiftly to market changes. Furthermore, by automating the cutting process, manufacturers can allocate human resources to more value-added tasks, further improving overall operational efficiency.

| Feature | Benefit | Impact on Efficiency | Cost Savings (% Reduction) |

|---|---|---|---|

| Precision Cutting | Ensures consistent sizes and shapes | Reduces material waste | 10% |

| Increased Speed | Faster production cycles | Improves overall output | 15% |

| Automation | Minimizes manual intervention | Enhances labor efficiency | 20% |

| Versatility | Suitable for various material types | Flexibility in production processes | 5% |

| Safety Features | Reduces risk of injury | Promotes a safer work environment | N/A |

In modern manufacturing, choosing the right cutting method can significantly impact efficiency and product quality. Traditional cutting methods, such as manual cutting or using outdated machines, often lead to inconsistencies and increased production time. These methods can be labor-intensive, requiring skilled workers to ensure precision, which may not always be achievable. As a result, manufacturers face challenges such as higher labor costs and potential wastage of materials.

Conversely, FIBC (Flexible Intermediate Bulk Container) belt cutting machines provide a modern solution to these issues. These machines offer precision cutting, reducing waste and promoting uniformity in production. The automation inherent in FIBC machines speeds up the cutting process, allowing for quicker turnaround times and reduced labor costs. Additionally, they require less skill to operate compared to traditional methods, enabling manufacturers to train workers quickly and efficiently.

Tips:

The advancement of technology in the manufacturing sector has significantly transformed the way FIBC (Flexible Intermediate Bulk Container) belt cutting is conducted. Innovative machinery now utilizes programmable logic controllers (PLCs) and advanced sensors to enhance precision, efficiency, and scalability in production lines. According to a recent report by the International Association for the Flexible Intermediate Bulk Container Industry, the use of automated cutting machines has increased production rates by approximately 35% while reducing material waste by up to 10%. This added efficiency not only translates into cost savings but also allows for quicker turnaround times in manufacturing processes.

Moreover, the integration of computer-aided design (CAD) systems into FIBC belt cutting machines has revolutionized product customization. Manufacturers can now create tailored designs with extreme accuracy, accommodating various customer specifications with minimal lead time. A study from MarketsandMarkets indicates that the global market for automated FIBC machinery is expected to grow at a CAGR of 6.5%, driven by these technological innovations. As industries increasingly prioritize sustainability and efficiency, the adoption of modern FIBC belt cutting machinery is set to become a critical factor in maintaining competitiveness in the manufacturing landscape.

This chart highlights the advantages of using a FIBC belt cutting machine, illustrating the significant benefits in terms of efficiency, waste reduction, cost savings, precision, and safety in modern manufacturing processes.

The use of a FIBC (Flexible Intermediate Bulk Container) belt cutting machine has become a game-changer in modern manufacturing, particularly in terms of production costs and waste reduction. According to a recent report from the International Packaged Goods Council, implementing automated cutting machines can reduce labor costs by as much as 30%, allowing manufacturers to allocate resources more efficiently. By automating the cutting process, manufacturers not only streamline their operations but also mitigate the risks associated with manual errors, which can lead to material wastage and higher operational costs.

Moreover, the environmental benefits of using a FIBC belt cutting machine are significant. The same report indicates that automated cutting can diminish material waste by approximately 25% due to its precision and ability to optimize fabric usage. This reduction in waste not only contributes to lower disposal costs but also aligns with the industry’s growing focus on sustainability. As businesses increasingly adopt eco-friendly practices, utilizing advanced machinery like the FIBC belt cutting machine is a strategic move that enhances both economic performance and environmental responsibility, ultimately shaping a more sustainable manufacturing landscape.