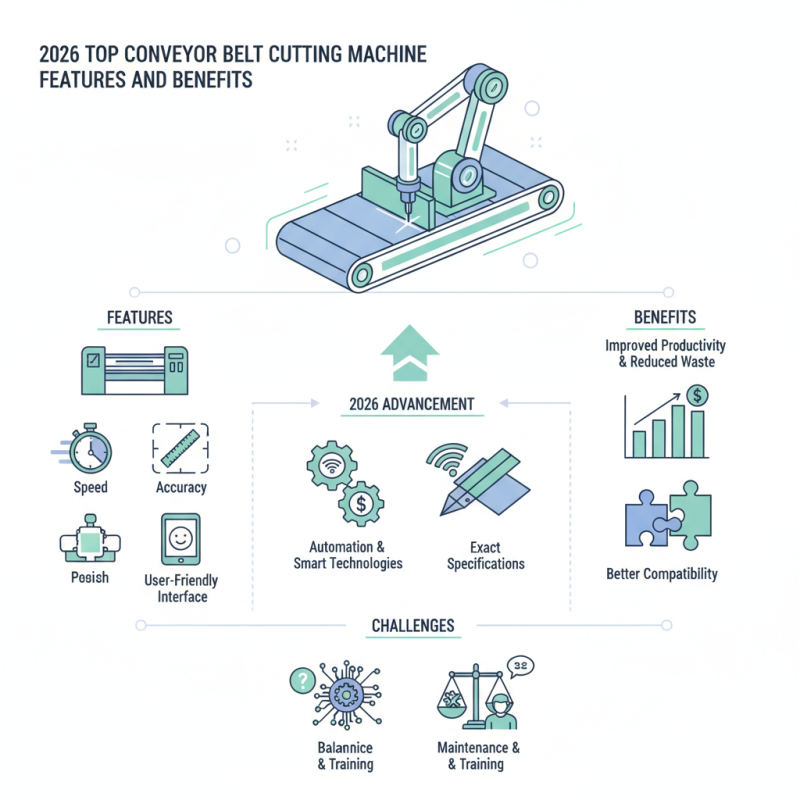

The Conveyor Belt Cutting Machine has become a vital tool in various industries. Its efficiency and precision streamline production processes. Features such as speed, accuracy, and user-friendly interfaces enhance its usability, making it indispensable for manufacturers.

In 2026, advancements in technology will bring even more benefits. Modern machines will incorporate automation and smart technologies, improving productivity and reducing waste. Cutting belts to exact specifications will ensure better compatibility with various applications. However, the complexity of these machines may pose challenges.

Understanding the features is essential for making informed decisions. Users must carefully assess their needs and the machine's capabilities. Balancing performance with cost is crucial. The right Conveyor Belt Cutting Machine can significantly impact output. Yet, one must not overlook potential drawbacks, such as maintenance challenges and operator training requirements.

In 2026, conveyor belt cutting machines have evolved significantly. They now offer precision cutting capabilities, enhancing efficiency in various industries. This innovation ensures that belts can be cut to exact specifications. Users can now cut belts up to 12 feet long with minimal error. This level of accuracy was previously hard to achieve.

Another exciting feature is the software integration. Advanced systems now allow for easy adjustments and custom patterns. Operators can program cuts directly into the machine, streamlining production lines. However, not all machines are user-friendly. Some require extensive training, which can slow down initial operations. It's a trade-off worth considering.

Safety enhancements are vital as well. Modern machines come equipped with locking mechanisms and emergency stops. These features reduce the risk of accidents significantly. Yet, some operators still overlook safety protocols. This oversight can lead to injuries, highlighting the need for ongoing training and awareness. Overall, while the advances are impressive, users must remain vigilant and informed.

Advanced conveyor belt cutting technology offers numerous benefits for industries reliant on efficient material handling. One key advantage is precision. With high-tech cutting machines, operators can achieve exact dimensions. This reduces waste and enhances production efficiency. A well-cut belt leads to improved equipment performance. Properly sized belts fit more securely, minimizing risks and downtime.

Another significant benefit is speed. Advanced machines can cut belts faster than manual methods. This efficiency translates to quicker production cycles. In today’s fast-paced environment, time is critical. Implementing cutting-edge technology can keep businesses competitive. Automated systems require less human intervention, lowering labor costs.

Tips: Always evaluate your cutting machine's capabilities. Regular maintenance ensures consistent performance. Consider investing in training for your staff. Knowledgeable operators will maximize machine potential. Keeping up with technology trends is vital. Some systems might not suit your specific needs, requiring careful consideration. Reflect on your processes regularly for improvements.

When analyzing conveyor belt cutting machines, a few factors stand out. Precision is key. Accurate cuts can reduce waste and improve efficiency. Features such as adjustable blade speeds allow for customization based on material thickness. Some machines offer easy blade changes, enhancing productivity during operation.

Another important aspect is security. Machines equipped with emergency stop buttons or safety guards provide added security for operators. Consider the ease of operation as well; user-friendly interfaces can significantly reduce the training time for new employees. A machine that is complicated may lead to frequent errors and frustration.

Tips: Always scrutinize machine specifications. Look for models that include detailed user manuals. Regular maintenance protocols are crucial to avoid breakdowns. Performance reliability can vary; it's wise to seek reviews from actual users. Don’t overlook the importance of customer support. Machines can have issues requiring expert assistance. Having access to good support can make a big difference.

In 2026, innovations in conveyor belt cutting processes will significantly enhance efficiency. New cutting machines will feature advanced laser technology for precise cuts. This ensures clean edges and minimizes material waste. Automation will play a crucial role. Many cutting machines will integrate AI to adjust the cutting speed based on belt material.

Here’s a tip: Regular maintenance of these machines is critical. It prevents overheating and prolongs their lifespan. Overlooked components can lead to errors.

Another exciting trend is the shift towards eco-friendly materials. These innovations aim to reduce environmental impact. However, some manufacturers may rush the transition, resulting in lower quality products. The industry must focus on balancing sustainability with performance.

Tip: Always test new materials in controlled conditions before full implementation. This can save time and money in the long run. Being cautious will help avoid failures that could disrupt operations.

| Feature | Description | Benefits |

|---|---|---|

| High Precision Cutting | Utilizes advanced laser technology for accurate cuts. | Ensures minimal material waste and improves product quality. |

| User-Friendly Interface | Equipped with a touchscreen control panel. | Increases operator efficiency and reduces training time. |

| Automated Operation | Incorporates robotics for automatic feeding and cutting. | Reduces labor costs and minimizes human error. |

| Advanced Safety Features | Includes emergency stop buttons and safety guards. | Enhances workplace safety and compliance with regulations. |

| Eco-Friendly Operation | Designed to minimize energy consumption. | Reduces operational costs and supports sustainability initiatives. |

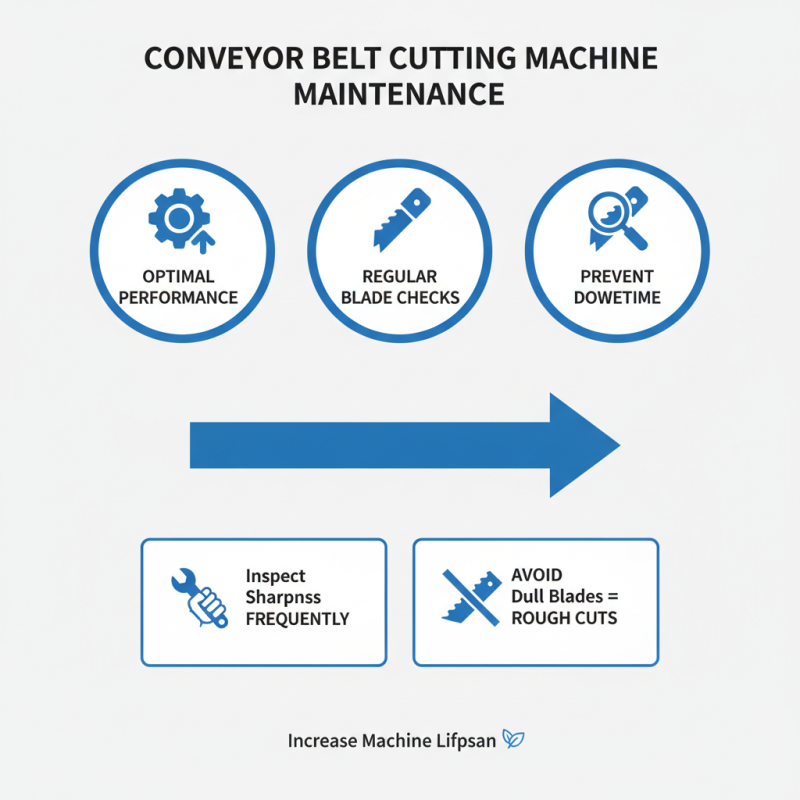

Maintaining conveyor belt cutting machines is essential for optimal performance. Regular checks on the blades can prevent unexpected downtime. Operators should inspect the blade sharpness frequently. Dull blades can lead to rough cuts and increased wear on the machine.

Safety is a critical aspect when using these machines. Proper training is necessary for all operators. They should understand how to operate the equipment safely. Additionally, wearing personal protective equipment, such as gloves and goggles, is essential. Even small accidents can lead to serious injuries.

Machine maintenance should include regular cleaning and lubrication. Dust and debris can compromise performance. Neglecting these tasks can result in costly repairs. Furthermore, operators must be aware of any unusual noises or vibrations, which could indicate issues. Reflecting on our practices can always lead to better safety and maintenance protocols.